Conveying belt module

A technology of conveyor belts and bumps, applied in the field of conveying, can solve the problems of insufficient limit force, affecting the transportation stability of the conveyor belt, sheet breakage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

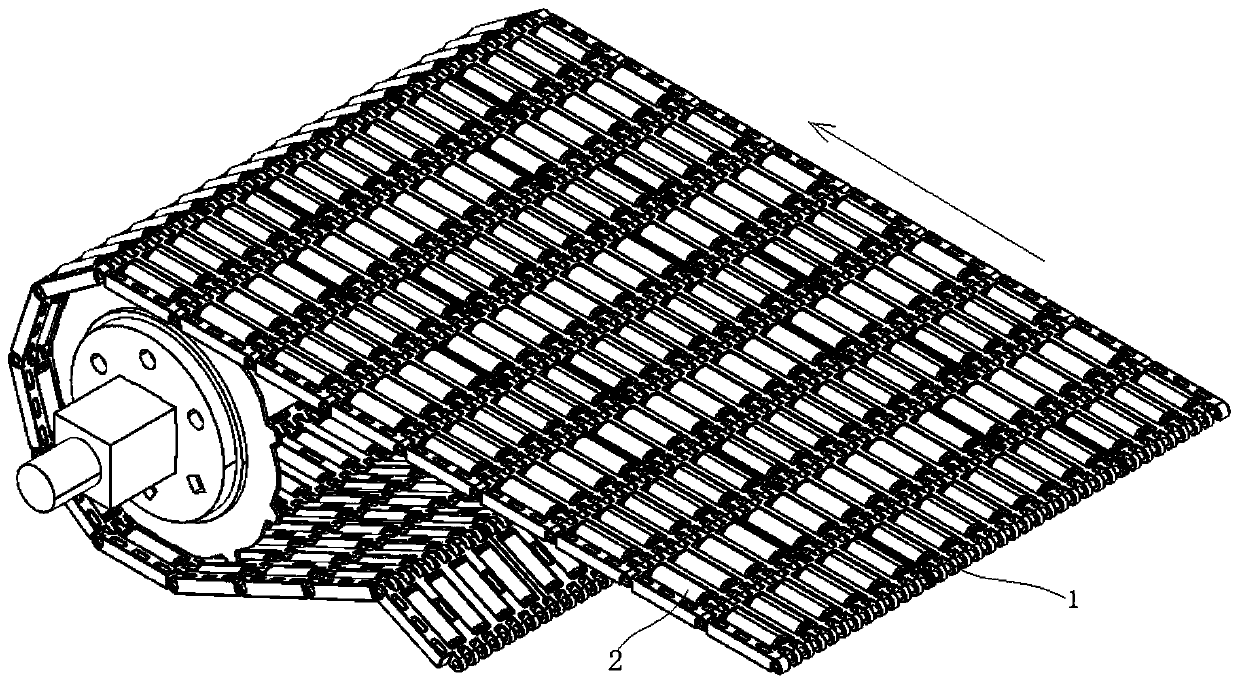

[0025] A conveyor belt module, which belongs to the partial module in the modular conveyor belt, such as figure 1 As shown, multiple modules can be spliced together to form a complete conveyor belt; there are longitudinally distributed slots on the lower surface of the conveyor belt, and the slots coincide with the teeth of the gear on the conveyor belt. When the gear rotates, the teeth of the gear The teeth drive the conveyor belt forward. Wherein a single conveyor belt module includes a sheet 1 and a ball 4 limited on the sheet 1 .

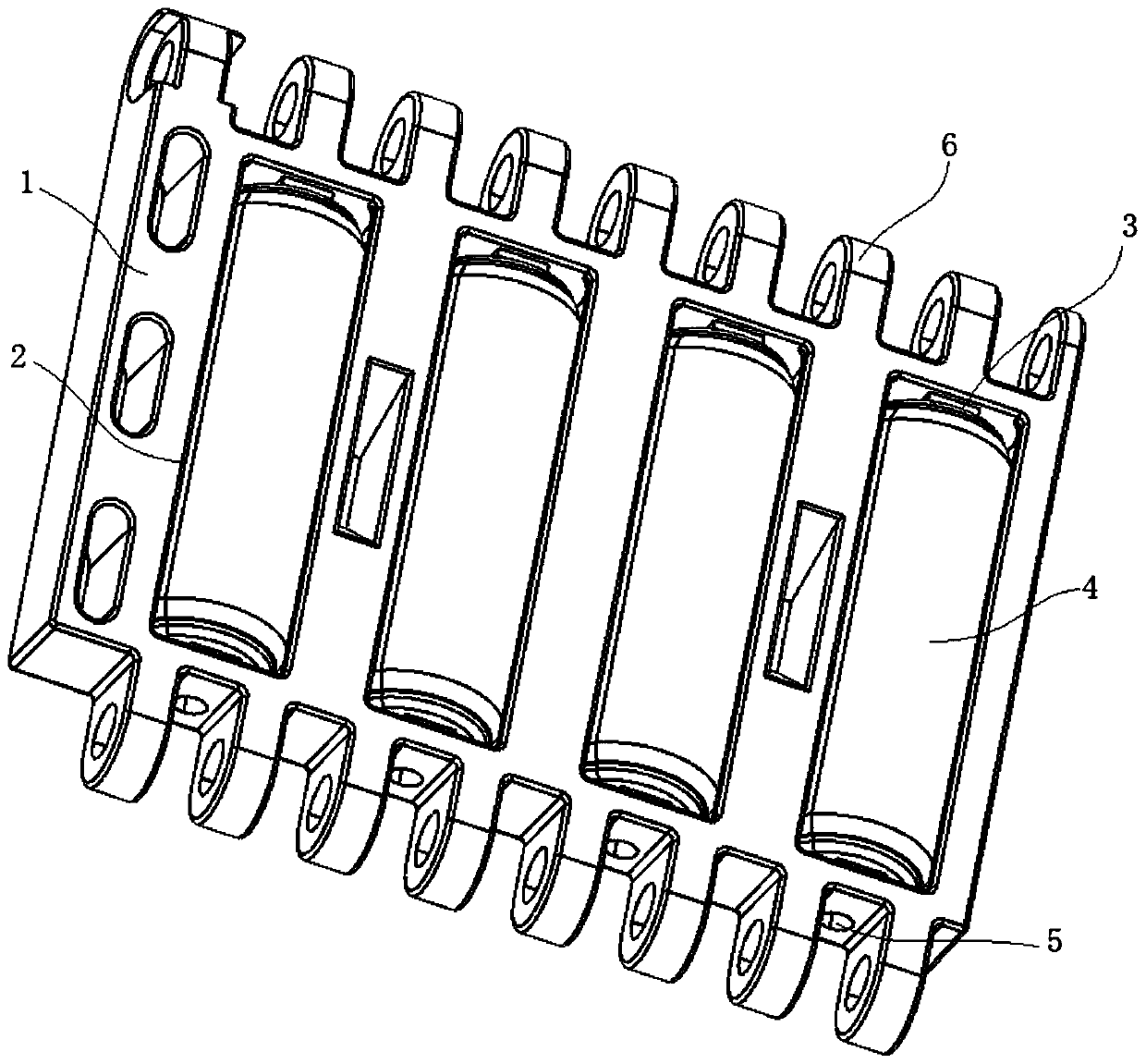

[0026] The width of the sheet 1 can be set according to actual conditions, such as Figure 2 ~ Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com