Membrane press system and method for production of shell-shaped tooth correction appliance

A dental appliance and lamination technology, applied in the field of orthodontics, can solve the problems of high labor intensity, low production efficiency, unsatisfactory orthodontic effect, etc., and achieve the effects of improving processing efficiency and shortening lamination time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

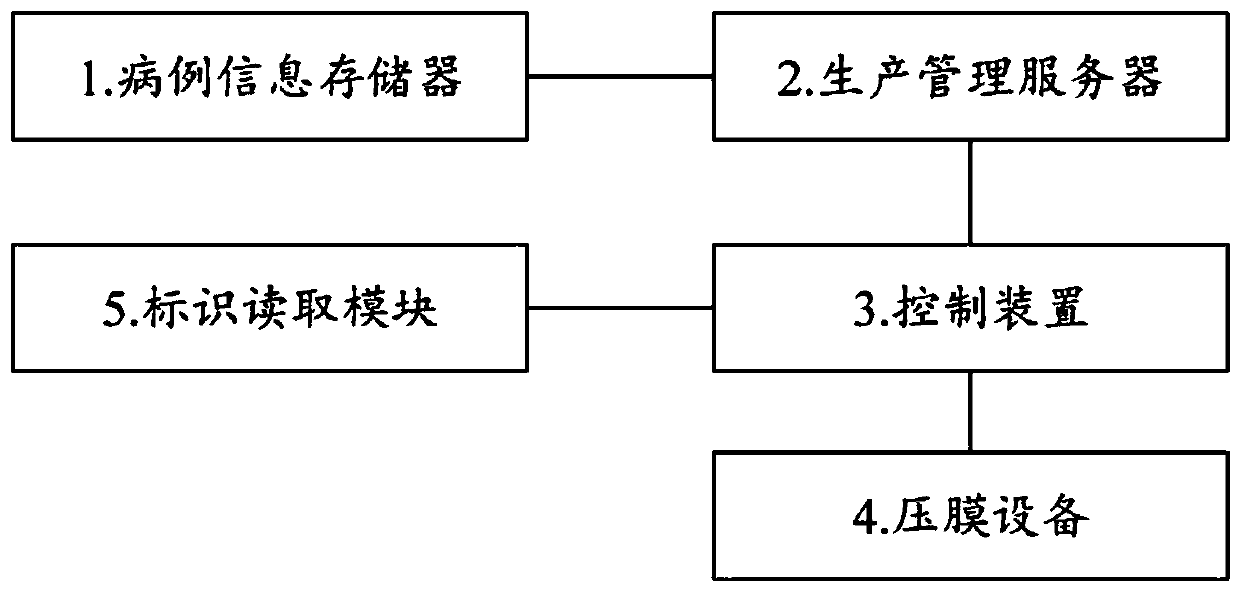

[0038] This embodiment provides a laminating system for the production of shell-shaped dental appliances, the principle diagram of which is as follows figure 1 As shown, it includes case information storage 1 , production management server 2 , control device 3 and lamination equipment 4 .

[0039] Case information storage 1 (such as ERP system, Enterprise Resource Planning, enterprise resource planning system), case information storage 1 can store the collected basic case information, and perform data processing on the basic case information, including according to the oral state of the orthodontic user, Comprehensive parameters such as age and gender are designed to meet the needs of orthodontic users. The correlative information of the lamination process of the shell-shaped dental appliance and the user identification information matching each shell-shaped dental appliance are designed, and the two information are associated and set. Forming interactive and usable case infor...

Embodiment 2

[0083] Based on Embodiment 1, this embodiment provides a laminating method for producing shell-shaped dental appliances, which is applied to the lamination system for producing shell-shaped dental appliances provided in Embodiment 1. The flow chart is as follows Figure 10 As shown, it specifically includes the following steps.

[0084] Step S100: Synchronously pick up the diaphragm and jaw model components and send them to the first station and the second station synchronously.

[0085] Specifically, the feeding signal is obtained, and according to the feeding signal, it is judged that when the diaphragm and the jaw model assembly reach the set position, the first driving device is controlled to drive the feeding assembly to move, and the feeding assembly is controlled to pick up the diaphragm and the jaw model assembly at the same time. Dental model components, and the diaphragm and dental model components are sent to the first station and the second station synchronously.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com