Bimetallic functionalized znco-mof catalytic material prepared by dry glue one pot method and its preparation method and application

A catalytic material and bimetallic technology, applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve high yield, enhanced stability, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

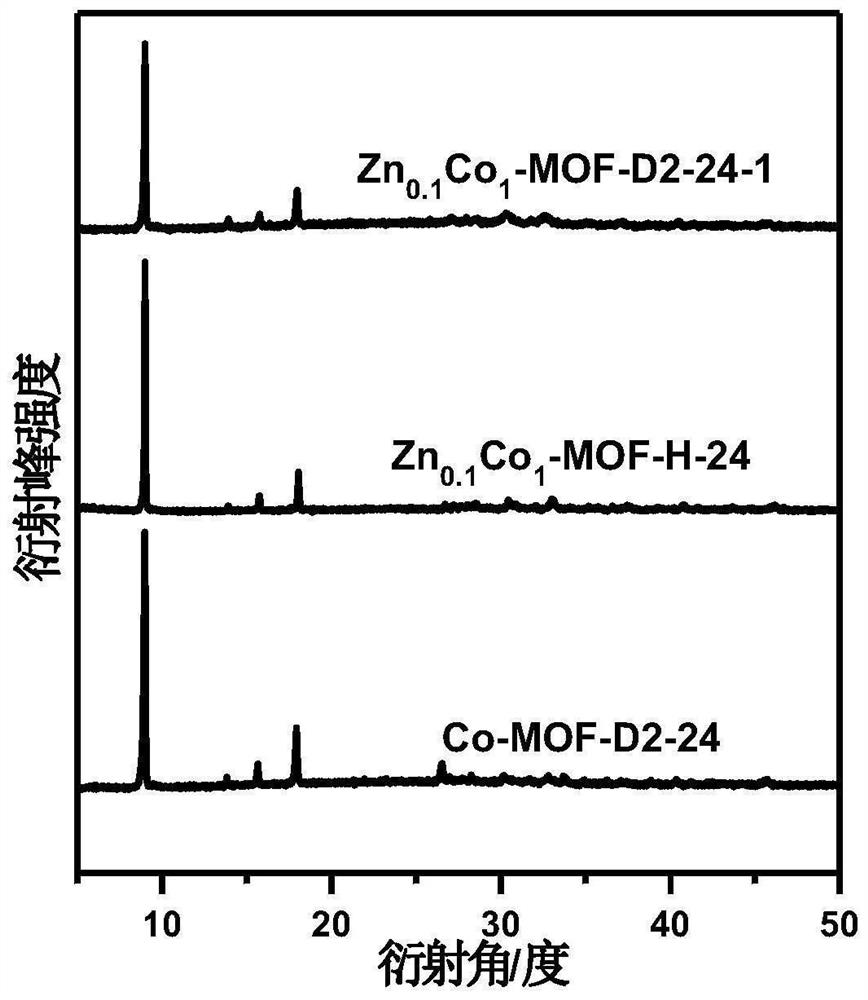

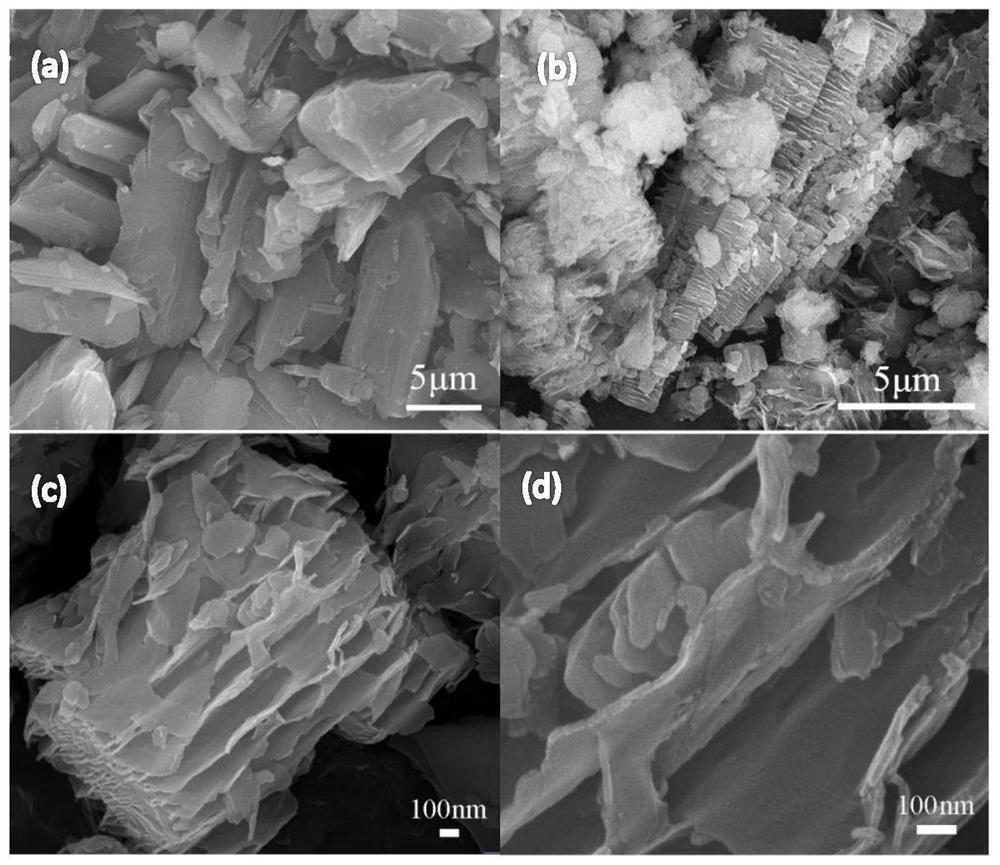

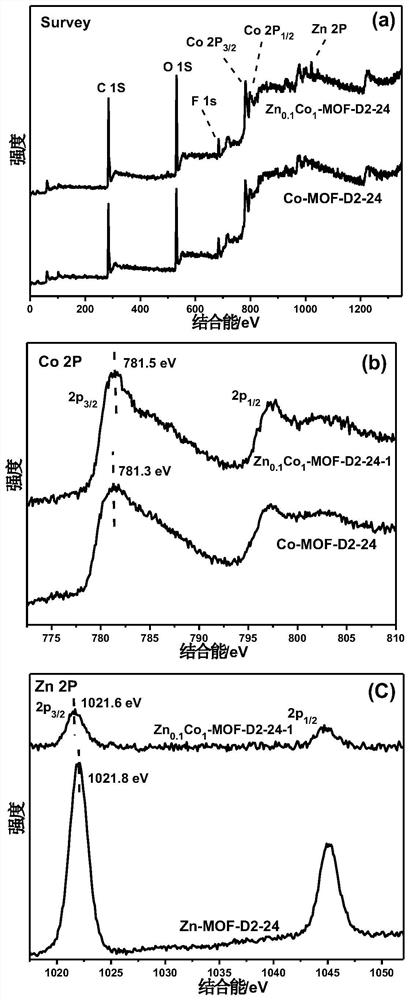

[0039] (1) The method for preparing bimetallic functionalized ZnCo-MOF material by dry glue one-pot method comprises the following steps:

[0040] The first step: the preparation of dry glue

[0041] Molar ratio metal cobalt salt: metal zinc salt: aromatic carboxylic acid: acetic acid: water = 1:0.1:1.1:1:463, add 6mmol cobalt acetate and 6.6mmol terephthalic acid to a polytetrafluoroethylene beaker with 2.222mol water Stir at room temperature for 30 minutes, mix well, add 6 mmol of acetic acid dropwise, stir for 20 minutes evenly, add 0.6 mmol of zinc chloride and 0.556 mol of water, continue to stir for 2 hours, then evaporate the tetrafluoroethylene beaker in an oven at 80 ° C to remove the reaction liquid to obtain dry glue, which is ground to obtain a pink powder substance, and 2.0 g of water is retained in the dry glue powder (the moisture content of the dry glue powder is 28.9%).

[0042] Step 2: Crystallization

[0043] Transfer the dry rubber powder prepared in the ...

Embodiment 2

[0048] (1) The method for preparing bimetallic functionalized ZnCo-MOF material by dry glue one-pot method comprises the following steps:

[0049] The first step: the preparation of dry glue

[0050] In molar ratio metal cobalt salt: metal zinc salt: aromatic carboxylic acid: acetic acid: water=1:0.05:1.05:1:278, 6mmol cobalt nitrate and 6mmol nitroterephthalic acid are added to polytetrafluoroethylene of 1.111mol water In the beaker, stir at room temperature for 30 minutes, mix well, add 6.3mmol of acetic acid dropwise, stir for 20min evenly, add 0.3mmol of zinc acetate and 0.556mol of water, continue to stir and react for 2h, then evaporate the tetrafluoroethylene beaker in an oven at 80°C The reaction solution was dried rubber, which was ground to obtain a pink powder substance, and 4.0 g of water was retained in the dried rubber powder (the moisture content of the dried rubber powder was 57.8%).

[0051] Step 2: Crystallization Transfer the dry rubber powder prepared in t...

Embodiment 3

[0055] (1) The method for preparing bimetallic functionalized ZnCo-MOF material by dry glue one-pot method comprises the following steps:

[0056] The first step: the preparation of dry glue

[0057] In molar ratio metal cobalt salt: metal zinc salt: aromatic carboxylic acid: acetic acid: water=1:0.5:1.5:0.5:463, 6mmol cobalt chloride and 9mmol 5-hydroxyisophthalic acid are added to the polytetrafluoroethylene of 2.222mol water Stir in a vinyl fluoride beaker at room temperature for 30 minutes, mix well, add 3 mmol acetic acid dropwise, stir for 20 min evenly, add 3.0 mmol zinc nitrate and 0.556 mol water, continue stirring for 2 hours, then steam the tetrafluoroethylene beaker in an oven at 80°C Remove the reaction liquid to obtain dry glue, and obtain a pink powder substance through grinding, and retain 0g of water in the dry glue powder (the moisture content of the dry glue powder is 0%).

[0058] Step 2: Crystallization

[0059] Transfer the dry rubber powder prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com