Embedded multi-channel water-helium double circulation cooling structure for large motor

A large-scale motor and cooling structure technology, applied in the magnetic circuit shape/style/structure, cooling/ventilation device, electrical components, etc., can solve the problems of poor cooling effect of air-cooled cooling pipes, single structure design, etc., and achieve satisfactory processing and manufacturing process. , The structure design is simple, the effect of improving the heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

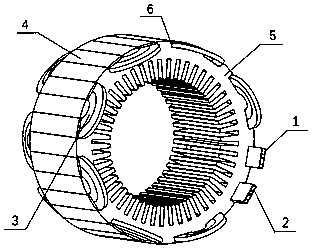

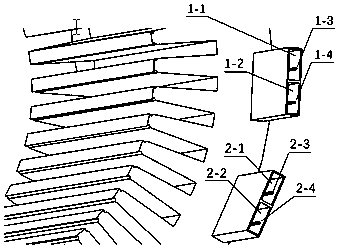

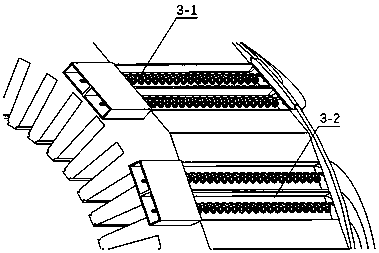

[0017] See attached figure 1 , attached figure 2 And attached image 3 , the present invention provides a technical solution: an embedded multi-channel water-helium double circulation cooling structure for large motors, including stator core 5, milling groove 6, cooling pipe 3, slot wedge 4, cooling pipe No. The first interface 1, the second interface 2 of the cooling pipe, is characterized in that the outside of the stator core 5 is provided with a milling groove 6, the cooling pipe 3 and the slot wedge 4 are embedded in the milling groove 6, and the slot wedge 4 is used to fix the cooling pipe 3.

[0018] Further, the first interface 1 of the cooling pipeline and the second interface 2 of the cooling pipeline are arranged at one end of the motor.

[0019] Further, the cooling pipes 3 are distributed along the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com