Anode material and preparation method thereof, prepared anode plate and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of reducing battery life, consuming heating energy, reducing system energy density, etc., and increasing the resistance to lithium precipitation. , The effect of heating energy consumption to ensure and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

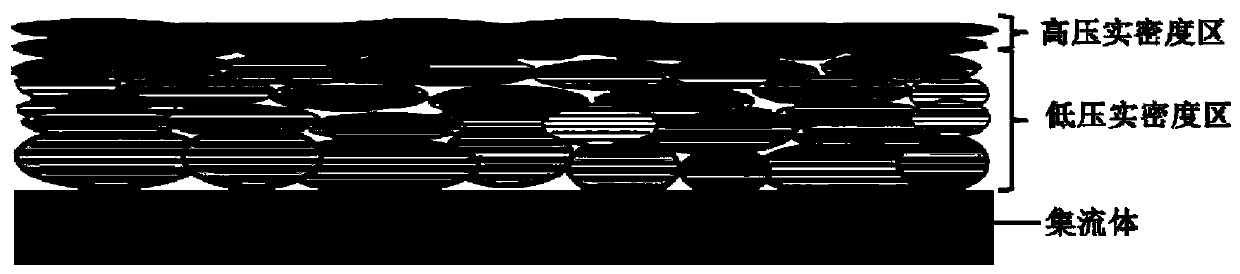

Method used

Image

Examples

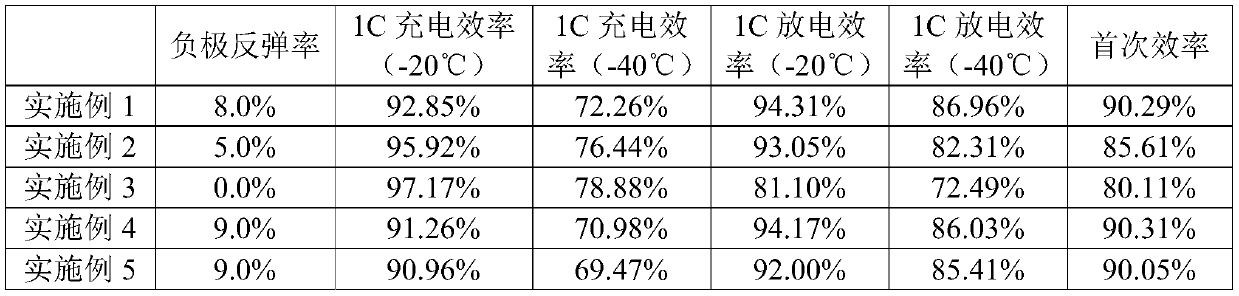

Embodiment 1

[0053] (1) drop into the scaly graphite of D50=5 μm and the furfurone resin hard carbon of D50=10 μm with the mass ratio of 9:1 in the mixing tank of double planetary mixer, with revolution speed 50r / min, rotation speed 1500r / min, After dispersing for 1 hour, a hard carbon-graphite composite negative electrode material was obtained;

[0054] (2) Add the composite negative electrode material, binder SBR, thickener CMC and conductive agent SP described in step (1) sequentially to the mixing tank with a mass ratio of 94:2:2:2, stir and disperse for 1 hour, and then add Add solvent deionized water of the same quality as the powder, and stir for 6 hours to obtain a hard carbon-graphite composite negative electrode slurry;

[0055] (3) Apply the above-mentioned composite negative electrode slurry evenly on the copper foil, and after drying in the oven, go through a cold press, die-cutting, and slitting to make a negative electrode sheet, and the surface density of the electrode shee...

Embodiment 2

[0059] (1) Put artificial graphite of D50=10 μm and acrylic resin hard carbon of D50=15 μm into the mixing tank of the planetary mixer with a mass ratio of 7.5:2.5, with a revolution speed of 30r / min and a rotation speed of 3000r / min, after dispersing for 3 hours , to obtain a hard carbon-graphite composite negative electrode material;

[0060] (2) Add the composite negative electrode material, binder SBR, thickener CMC and conductive agent SP described in step (1) sequentially to the mixing tank with a mass ratio of 94:2:2:2, stir and disperse for 1 hour, and then add Add solvent deionized water of the same quality as the powder, and stir for 6 hours to obtain a hard carbon-graphite composite negative electrode slurry;

[0061] (3) Evenly coat the above-mentioned composite negative electrode slurry on the copper foil, and after drying in the oven, go through a cold press, die-cutting, and stripping to make negative electrode sheets, and the surface density of the electrode sh...

Embodiment 3

[0064] (1) Drop into the natural aphanitic graphite of D50=15 μm and the epoxy resin hard carbon of D50=20 μm with the mass ratio of 5:5 in the mixing cylinder of planetary mixer, with revolution speed 10r / min, rotation speed 200r / min , after dispersing for 5 hours, a hard carbon-graphite composite negative electrode material was obtained;

[0065] (2) Add the composite negative electrode material, binder SBR, thickener CMC and conductive agent SP described in step (1) sequentially to the mixing tank with a mass ratio of 94:2:2:2, stir and disperse for 1 hour, and then add Add solvent deionized water of the same quality as the powder, and stir for 6 hours to obtain a hard carbon-graphite composite negative electrode slurry;

[0066] (3) Evenly coat the above-mentioned composite negative electrode slurry on the copper foil, and after drying in the oven, go through a cold press, die-cutting, and stripping to make negative electrode sheets, and the surface density of the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com