Wool light-carbonization weeding process

A wool and process technology, applied in the field of wool light carbon weeding process, can solve the problems of the difficulty of smooth and efficient circulation of cleaning water, the reduction of wool cleaning efficiency and quality, and the difficulty in applying wool weeding processing, etc., so as to reduce the number of carding processes and reduce carding. Processing times, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further describe the present invention, below in conjunction with accompanying drawing, further set forth the specific implementation of a kind of wool light carbon weeding process, following example is explanation of the present invention and the present invention is not limited to following example.

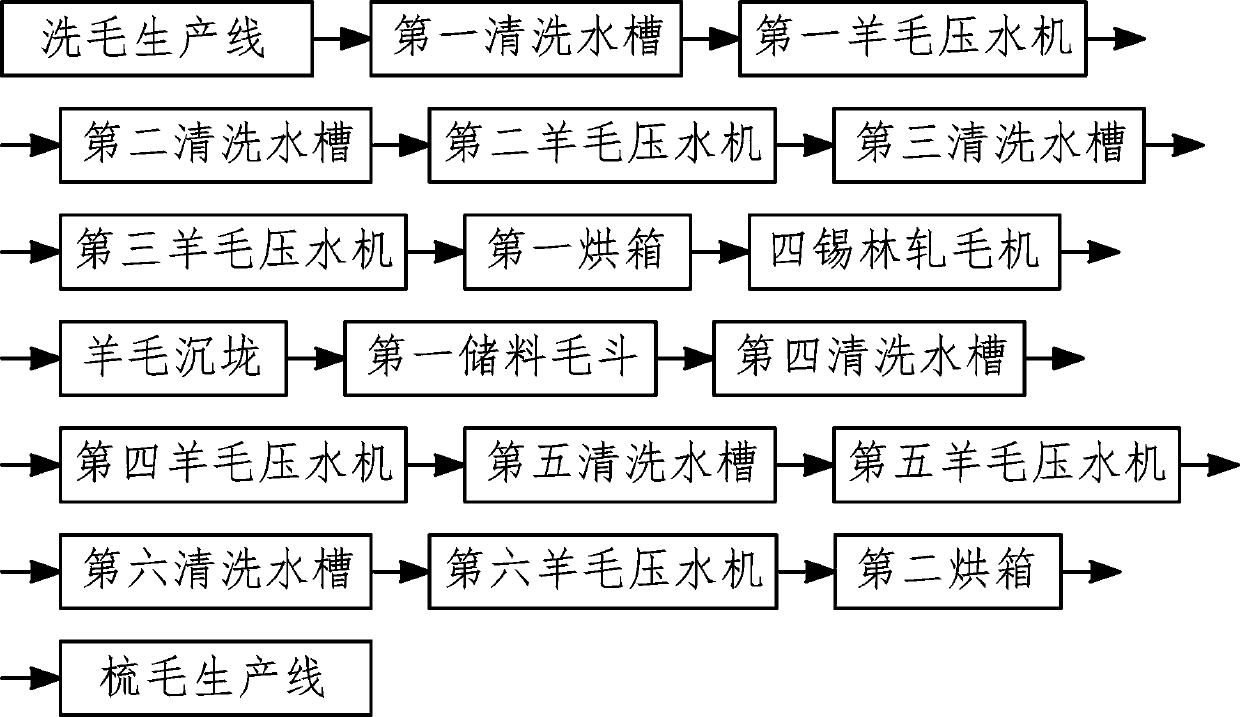

[0041] like figure 1 Shown, a kind of wool light carbon weeding technique of the present invention comprises the following steps:

[0042] Step 1: The wool that has been processed in the previous wool scouring production line is sent to the first washing tank in sequence. Wool detergent is added to the washing water in the first washing tank, and the temperature in the first washing tank is adjusted to 45°C. -50°C, the washing time of the wool in the first washing tank is 3 minutes, and the first washing tank is used to remove some of the remaining grease and impurities in the washed wool, and to protect the fibers of the wool before it enters the acid;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com