Cold ironing membrane for digital printing machine and preparation process of cold ironing membrane

A technology for printing machine and preparation process, which is applied in the field of cold stamping film for digital printing machine and its preparation process, which can solve the problems of narrow application range, lack of anti-counterfeiting, simplicity, etc. wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A cold stamping film for a digital printing machine, comprising a PET hot stamping base material, a separation layer, a moldable laser information layer and a UV medium layer arranged in sequence;

[0050] Wherein, the separation layer comprises the following components by weight percentage:

[0051] Waterborne Acrylic 12%

[0052] Water 26.9%

[0053] Ethanol 61.1%;

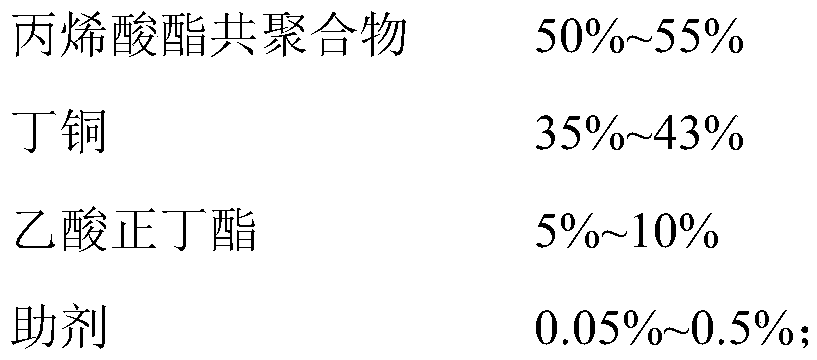

[0054] Wherein, the moldable laser information layer includes the following components by weight percentage:

[0055]

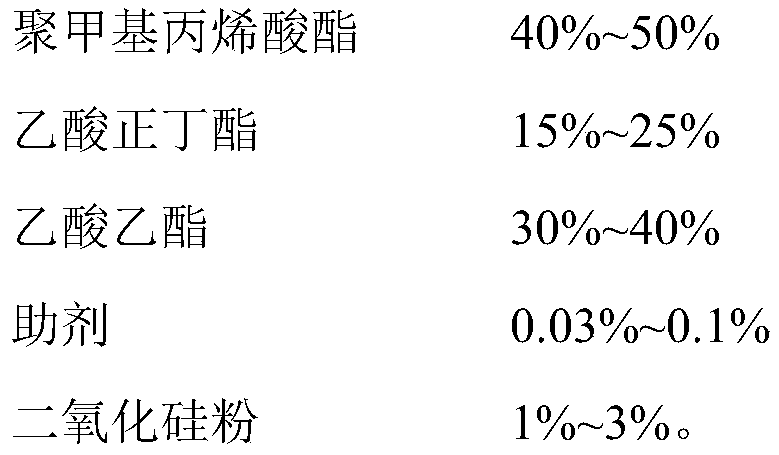

[0056] The UV medium layer comprises the following components by weight percentage:

[0057]

[0058] Among them, the auxiliary agent is a dispersant.

[0059] Above-mentioned a kind of preparation technology of digital printing machine cold stamping film, it comprises the following steps:

[0060] The first step, the preparation of the composition of the separation layer: after mixing the water-based acrylic acid and water of the formula quantity, then adding the ethanol of t...

Embodiment 2

[0065]A cold stamping film for a digital printing machine, comprising a PET hot stamping base material, a separation layer, a moldable laser information layer and a UV medium layer arranged in sequence;

[0066] Wherein, the separation layer comprises the following components by weight percentage:

[0067] Waterborne Acrylic 10%

[0068] water 30%

[0069] Ethanol 60%;

[0070] Wherein, the moldable laser information layer includes the following components by weight percentage:

[0071]

[0072] The UV medium layer comprises the following components by weight percentage:

[0073]

[0074] Among them, the auxiliary agent is a dispersant.

[0075] Above-mentioned a kind of preparation technology of digital printing machine cold stamping film, it comprises the following steps:

[0076] The first step, the preparation of the composition of the separation layer: after mixing the water-based acrylic acid and water of the formula quantity, then adding the ethanol of the fo...

Embodiment 3

[0081] A cold stamping film for a digital printing machine, comprising a PET hot stamping base material, a separation layer, a moldable laser information layer and a UV medium layer arranged in sequence;

[0082] Wherein, the separation layer comprises the following components by weight percentage:

[0083] Waterborne Acrylic 15%

[0084] water 20%

[0085] Ethanol 65%;

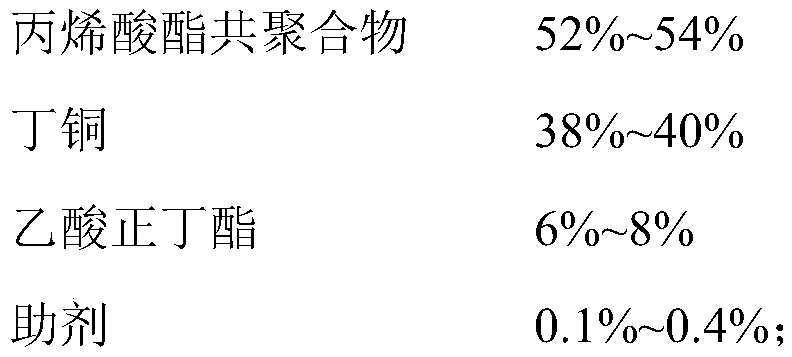

[0086] Wherein, the moldable laser information layer includes the following components by weight percentage:

[0087]

[0088] The UV medium layer comprises the following components by weight percentage:

[0089]

[0090] Among them, the auxiliary agent is a dispersant.

[0091] Above-mentioned a kind of preparation technology of digital printing machine cold stamping film, it comprises the following steps:

[0092] The first step, the preparation of the composition of the separation layer: after mixing the water-based acrylic acid and water of the formula quantity, then adding the ethanol of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com