Ultrasonic spindle and ultrasonic machine tool comprising same

An ultrasonic and spindle technology, which is applied to the accessories of tool holders, fluids using vibration, metal processing machinery parts, etc., can solve the problems of difficult alignment, thin conductive rings and conductive inserts, and high alignment accuracy requirements. Achieve the effects of avoiding leakage, eliminating potential safety hazards, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

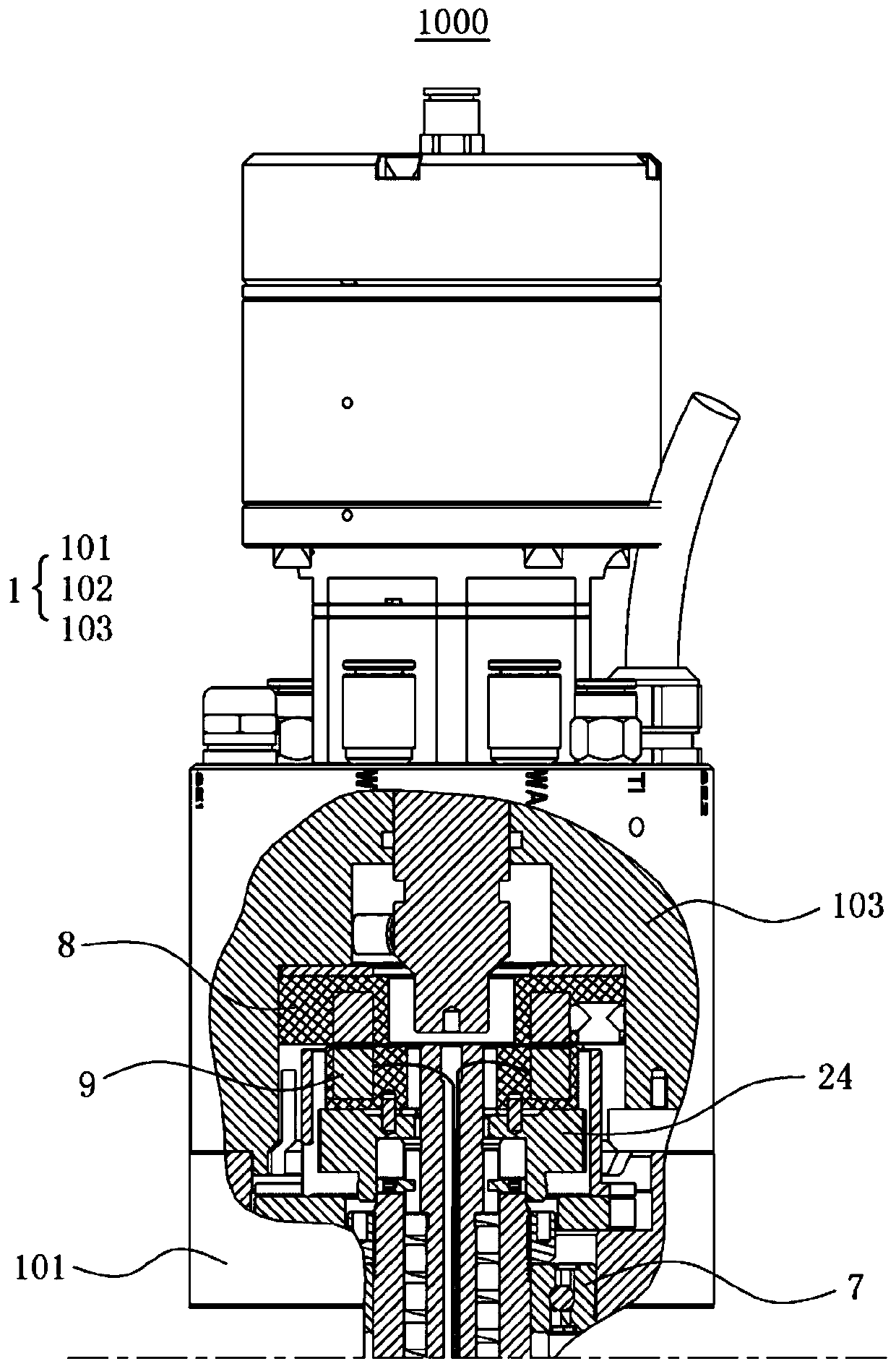

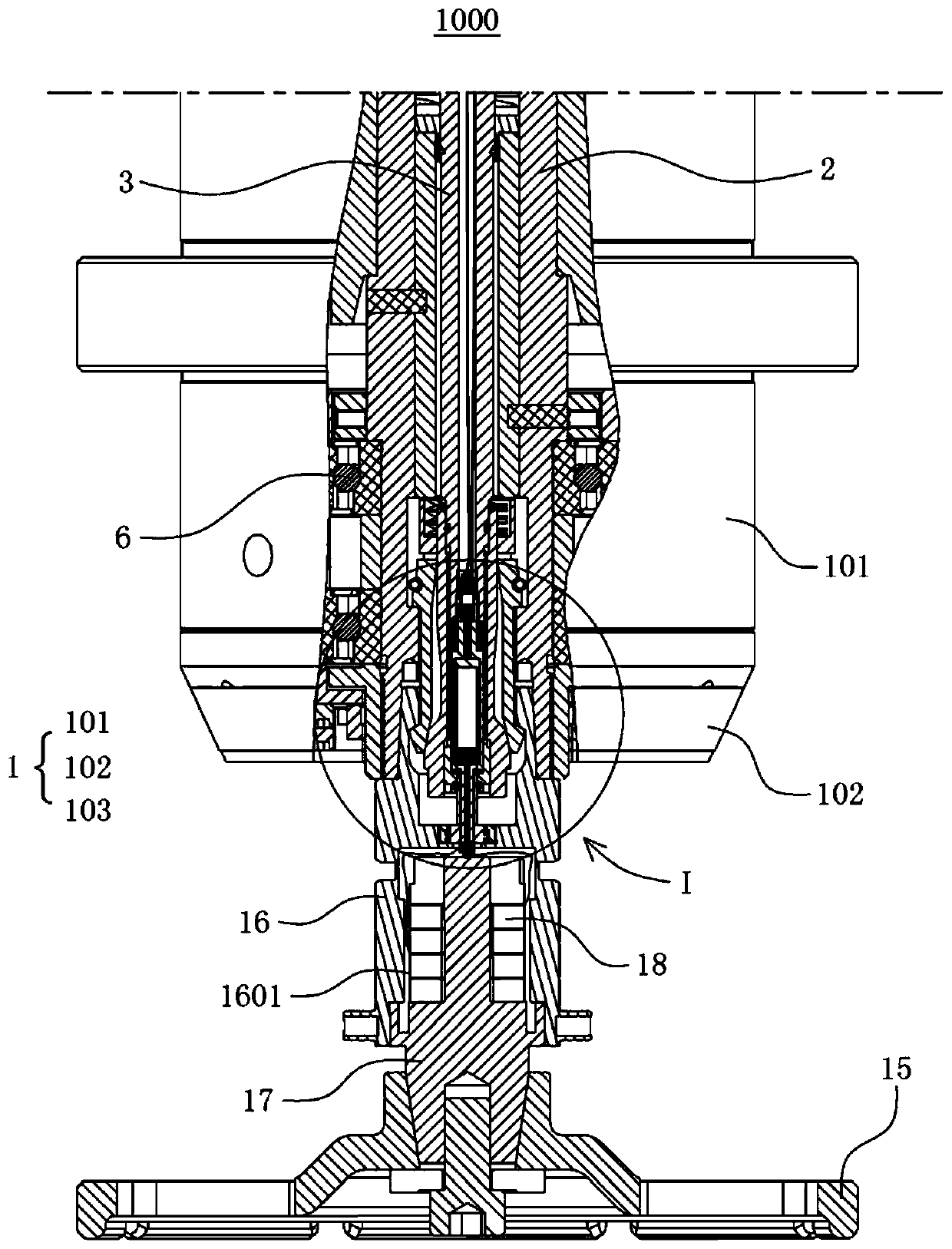

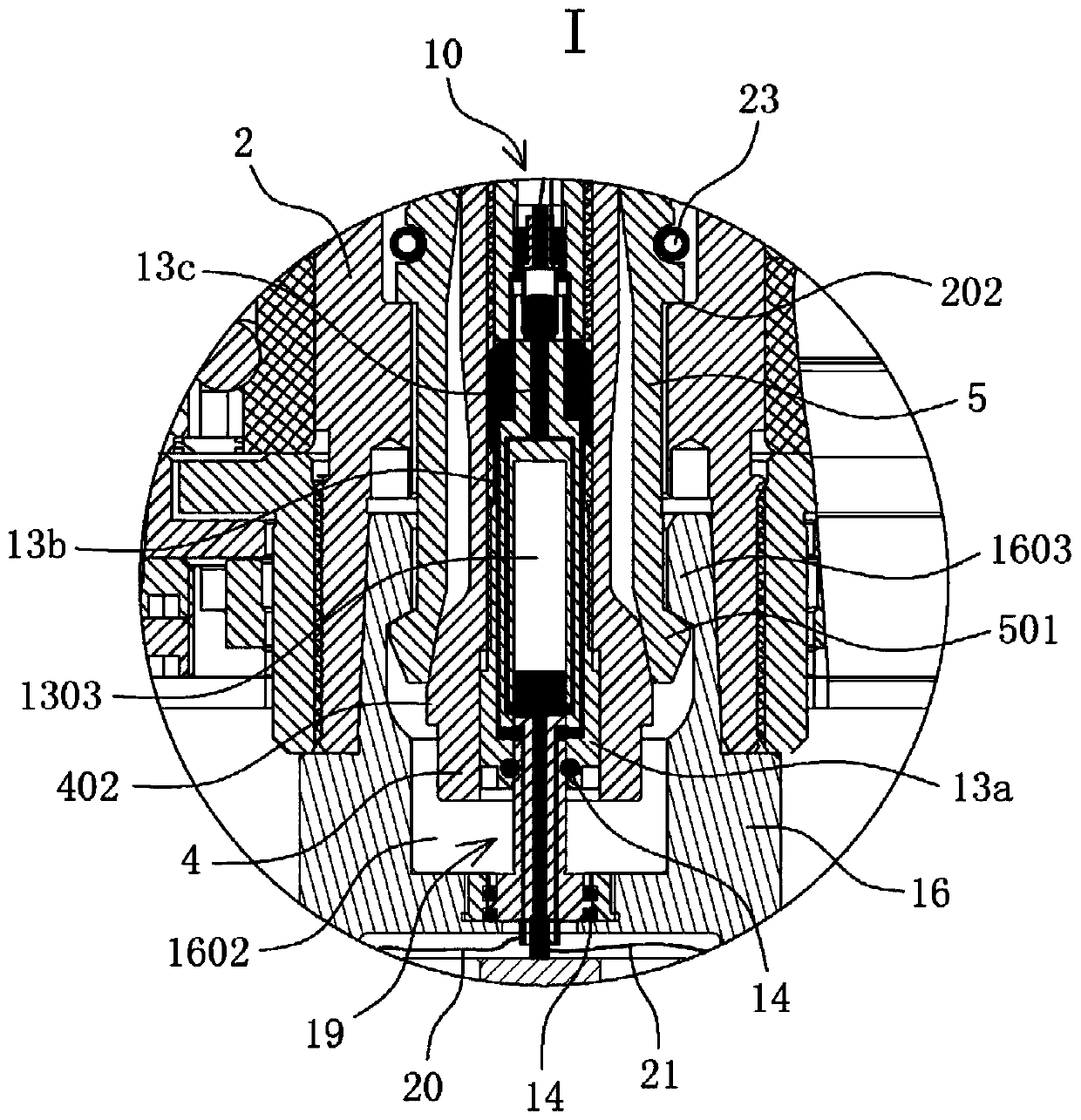

[0062] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides an ultrasonic spindle 1000, which mainly includes a cylinder base 1, a rotating shaft 2, a push rod 3, a sleeve body 4, a pull claw 5 and an ultrasonic processing assembly.

[0063] Such as Figure 1 to Figure 5 As shown, the cylinder base 1 is a fixed part, and the rotating shaft 2 is rotatably installed in the cylinder base 1; the inside of the rotating shaft 2 is provided with a cavity, and the push rod 3 is arranged in the cavity and can slide along the cavity, rotate The front end of the shaft 2 is provided with a sleeve hole 201 that communicates with the cavity; the sleeve body 4 is provided with a through hole 401 that runs through its front and rear ends, and the wall of the through hole 401 is provided with a first connecting thread 403, and the front end of the push rod 3 passes through The first connecting thread is screwed to the hole wall of the through hole 4, so tha...

Embodiment 2

[0089] Such as Figure 10 As shown, the embodiment of the present invention provides an ultrasonic machine tool, which mainly includes an ultrasonic power supply 2000 and the ultrasonic main shaft 1000 provided in Embodiment 1, wherein the wireless transmitting component 8 of the ultrasonic main shaft 1000 is electrically connected to the ultrasonic power supply 2000.

[0090]To sum up, the embodiment of the present invention provides an ultrasonic spindle 1000 and an ultrasonic machine tool including it. Compared with the prior art, the ultrasonic spindle 1000 has the advantages of easy maintenance, convenient disassembly and assembly, stable electrical conduction, high safety, The ultrasonic machine tool adopts the above-mentioned ultrasonic spindle 1000, so it also has the advantages of stable electrical conduction and good processing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com