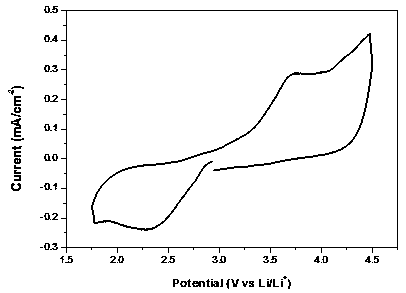

Method for preparing nano Co3O4/carbon nanotube integral air electrode catalysis material

A technology of carbon nanotubes and catalytic materials, which is applied in the field of preparation of nano-Co3O4/carbon nanotube integrated air electrode catalytic materials, can solve the problems of easy fragmentation of conductive network, deterioration of cycle stability, and low stability of electrode catalysis. Achieve excellent chemical stability and mechanical strength, improve charge and discharge capacity and cycle performance, and achieve large bidirectional catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A nano-Co 3 o 4 The preparation method of / carbon nanotube integrated air electrode catalytic material, concrete implementation is to carry out according to the following steps:

[0033] (1) Preparation of oxygen-containing functional groups on the surface of pure carbon nanotubes

[0034] The tubular reactor was heated to 450°C in the air, and the pure carbon nanotubes were placed in it for surface oxidation treatment for 0.1h, so that the surface of the pure carbon nanotubes was oxidized to achieve surface functionalization, and pure carbon nanotubes with oxygen-containing functional groups on the surface were obtained. Tube.

[0035] (2) Nano Co 3 o 4 / Preparation of carbon nanotube integrated air electrode catalytic material

[0036] Take 100mg of surface-oxidized pure carbon nanotubes prepared in step (1), mix 11mg of cobalt acetylacetonate and 12.5ml of ethylene glycol in a three-necked flask, stir at room temperature for 20min, and pass argon into the three-...

Embodiment 2

[0041] (1) Preparation of oxygen-containing functional groups on the surface of nitrogen-doped carbon nanotubes

[0042] The tubular reactor was heated to 440°C in the air, and the nitrogen-doped carbon nanotubes were placed in it for surface oxidation treatment for 0.5h, so that the surface of the nitrogen-doped carbon nanotubes was oxidized to achieve surface functionalization, and the surface oxygen-containing functional groups were obtained. nitrogen-doped carbon nanotubes.

[0043] (2) Nano Co 3 o 4 / Preparation of carbon nanotube integrated air electrode catalytic material

[0044] Take 100mg of surface oxidized nitrogen-doped carbon nanotubes prepared in step (1), mix 20mg of cobalt nitrate and 15ml of ethylene glycol in a three-necked flask, stir at room temperature for 30min, and blow nitrogen into the three-necked flask Then start to heat and reflux, raise the temperature to 265°C and keep it for 0.5h, and then start to cool down. After reaching room temperature,...

Embodiment 3

[0048] (1) Preparation of oxygen-containing functional groups on the surface of sulfur-doped carbon nanotubes

[0049] The sulfur-doped carbon nanotubes were placed in concentrated nitric acid for surface oxidation treatment for 3 hours, then filtered and washed, and then dried in an oven at 70°C for 24 hours, so that the surface of the sulfur-doped carbon nanotubes was oxidized to achieve surface functionalization, and obtained Sulfur-doped carbon nanotubes with surface oxygen functional groups.

[0050] (2) Nano Co 3 o 4 / Preparation of carbon nanotube integrated air electrode catalytic material

[0051] Take 100mg of surface oxidized sulfur-doped carbon nanotubes prepared in step (1), mix 20mg of cobalt hydroxide and 30ml of absolute ethanol, stir at room temperature for 30min, place in a high-temperature reaction kettle, and heat up to 200°C After keeping it for 10 hours, it started to cool down. After reaching room temperature, it was suction-filtered, washed with abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap