Optimized dried orange peel processing process

A processing technology and tangerine peel technology, which is applied in the field of optimal tangerine peel processing technology, can solve the problems that the process parameters are not specified in detail, the comprehensive effect of multiple components is ignored, and the quality of the dried tangerine peel pieces is not uniform. Subjective preference error, avoiding uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

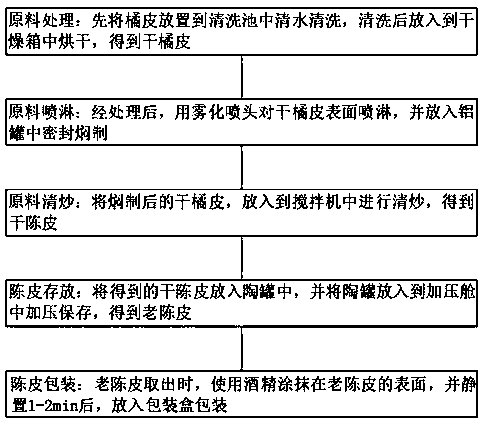

[0032] A kind of preferred tangerine peel processing technology, comprises concrete steps as follows:

[0033] (1), raw material processing: first place the orange peel in the cleaning pool to clean with water, after cleaning, put it into a drying box to dry to obtain dry orange peel, before drying, first cut the orange peel into shreds, and the cutting width is 4cm , drying includes the following specific steps:

[0034] (1.1) Preliminary drying: first control the drying oven at 40°C, and dry the orange peel without ventilation for 30-40min. During the sealing drying, shake it every 6min, and stop heating for 1min at the same time;

[0035] (1.2), efficient drying: after preliminary drying, the drying oven is heated to 80 ° C, and the water vapor in the drying oven is discharged, and dried for 10 min;

[0036] (1.3), cooling irradiation: after efficient drying, take out the orange peel, and after cooling to room temperature, put it in the sun for 4 hours;

[0037] (2), raw ...

Embodiment 2

[0042] A kind of preferred tangerine peel processing technology, comprises concrete steps as follows:

[0043] (1), raw material processing: first place the orange peel in the cleaning pool to clean with water, after cleaning, put it into a drying box to dry to obtain dry orange peel, before drying, first cut the orange peel into shreds, and the cutting width is 4cm , drying includes the following specific steps:

[0044] (1.1) Preliminary drying: first control the drying oven at 40°C, and dry the orange peel without ventilation for 30-40min. During the sealing drying, shake it every 6min, and stop heating for 1min at the same time;

[0045] (1.2), efficient drying: after preliminary drying, the drying oven is heated to 80 ° C, and the water vapor in the drying oven is discharged, and dried for 10 min;

[0046] (1.3), cooling irradiation: after efficient drying, take out the orange peel, and after cooling to room temperature, put it in the sun for 4 hours;

[0047] (2), raw ...

Embodiment 3

[0052]A kind of preferred tangerine peel processing technology, comprises concrete steps as follows:

[0053] (1), raw material processing: first place the orange peel in the cleaning pool to clean with water, after cleaning, put it into a drying box to dry to obtain dry orange peel, before drying, first cut the orange peel into shreds, and the cutting width is 4cm , drying includes specific steps as follows:

[0054] (1.1) Preliminary drying: first control the drying oven at 40°C, and dry the orange peel without ventilation for 30-40min. During the sealing drying, shake it every 6min, and stop heating for 1min at the same time;

[0055] (1.2), efficient drying: after preliminary drying, the drying oven is heated to 80 ° C, and the water vapor in the drying oven is discharged, and dried for 10 min;

[0056] (1.3), cooling irradiation: after efficient drying, take out the orange peel, and after cooling to room temperature, put it in the sun for 4 hours;

[0057] (2), raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com