Composite separator for secondary battery

A composite diaphragm and adhesive technology, which is applied in the field of composite diaphragms and electrochemical components, can solve the problems of high capacity efficiency reduction, floating phenomenon, and difficulty in large-scale, so as to improve life, improve distortion or floating phenomenon, and reduce voids. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] Prepare core-shell organic particle binder (A) as binder, described core-shell organic particle binder (A) is made up of core and shell, and described core is made of butyl acrylate and methyl methacrylate The shell is composed of butyl acrylate, methyl methacrylate, styrene and acrylonitrile polymers, the glass transition temperature of the core is 80°C, the glass transition temperature of the shell is 30°C, and the average particle size The diameter (D50) is 0.8 μm.

[0171] Disperse 20% by weight of the core-shell organic particle binder (A), 79.5% by weight of alumina particles with an average particle size of 0.6 μm, and 0.5% by weight of boehmite particles with an average particle size of 1.5 μm in water to make a slurry. The solids content of the slurry was 18% by weight.

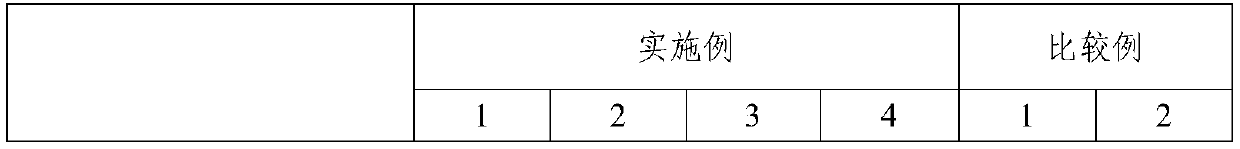

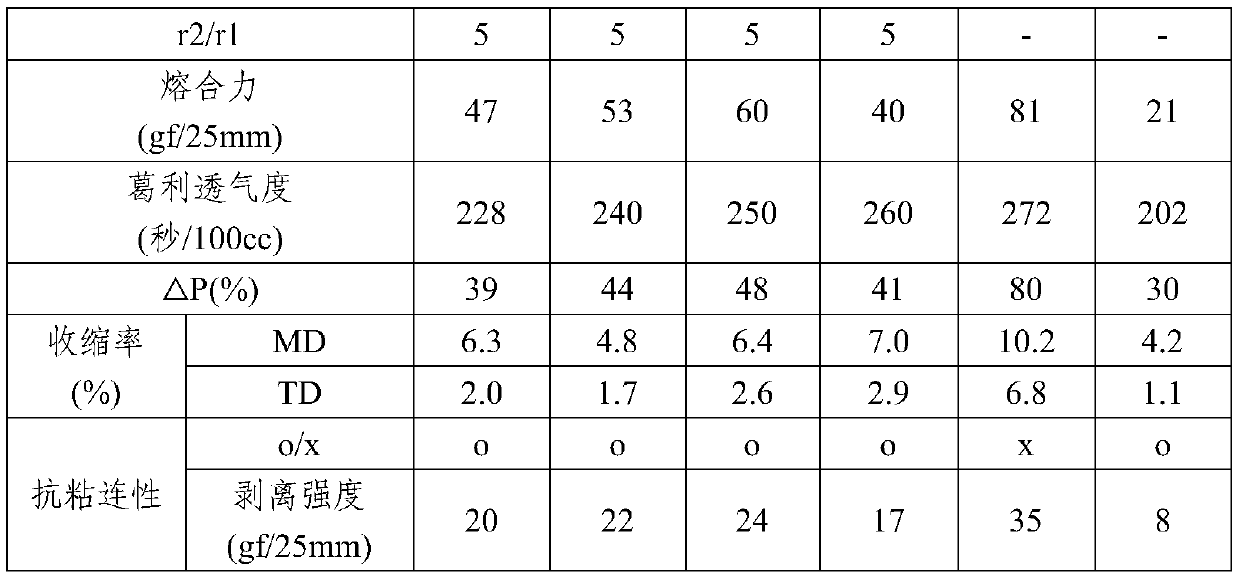

[0172] On both surfaces of a polyethylene-based porous substrate (SK New Technology Co., Ltd., ENPASS) with a Gurley air permeability of 150 seconds / 100cc and a thickness of 9 μm, it was coa...

Embodiment 2

[0175] In Example 1, in addition to further adding 6% by weight of single-layer latex organic particles (B) with a glass transition temperature of 10°C and an average particle diameter (D50) of 0.2 μm as a compound composed of butyl acrylate and methyl methacrylate In addition to the particles with a single-layer structure composed of copolymers, and the content of the organic particles (A) with an average particle diameter of 0.8 μm was changed from 20% by weight to 14% by weight to prepare the slurry, the same method as in Example 1 was used. Methods to fabricate composite diaphragms.

[0176] The physical properties of the fabricated composite separators were measured and shown in Table 1 below.

Embodiment 3

[0178] Except using the core-shell organic particle binder (C) instead of the core-shell organic particle binder of Example 1, proceed in the same manner as in Example 1, wherein the core-shell organic particle binder (C) consists of a core and a shell, the core is composed of a copolymer of butyl acrylate and methyl methacrylate, the shell is composed of an ethylene-vinyl acetate copolymer, and the glass transition temperature of the core is 80°C, The glass transition temperature of the shell is -20°C, and the average particle diameter (D50) is 0.8 µm.

[0179] The physical properties of the fabricated composite separators were measured and shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com