Novel PU and PVC mixed artificial leather and preparation method and system thereof

A manufacturing method and technology of artificial leather, applied in the field of artificial leather, can solve the problems of inconvenient use of artificial leather, and achieve the effects of good performance, soft surface and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

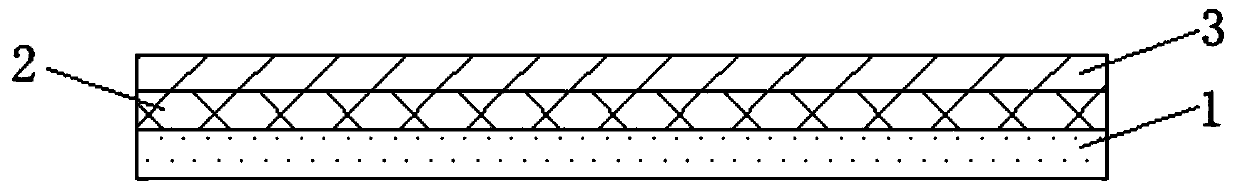

[0034] A new PU and PVC mixed artificial leather, comprising a base layer 1, the base layer 1 includes acrylic fiber and polyester fiber, the top and bottom of the base layer 1 are provided with a PU layer 2, the top of the PU layer 2 is provided with a PVC layer 3, the PU layer 2 and the The thickness of the PVC layer 3 is 0.1-0.3mm, and the thickness of the base layer 1 is 0.3-0.5mm.

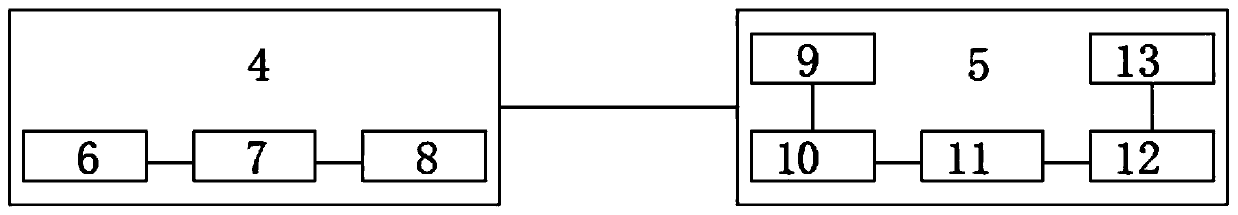

[0035] A method for manufacturing a novel PU and PVC mixed artificial leather, comprising the following steps: step a: through solid conveying, compacting, melting, shear mixing and extruding molding of PVC material through a screw extruder, to obtain a PVC layer 3; step b : acrylic fibers and polyester fibers are made into a base layer 1 by a textile machine, and the base layer 1 is used as a base cloth, and the base layer 1 is pre-wetted in a pre-solidification tank, and squeezed dry after pre-wetting; step c: after pre-wetting, the two sides of the base layer 1 Coating the PU layer 2, then ...

Embodiment 2

[0038] In embodiment 1, add following steps again:

[0039] The base layer 1 is formed by blending acrylic fibers and polyester fibers at a ratio of 1:1.

[0040] A new PU and PVC mixed artificial leather, comprising a base layer 1, the base layer 1 includes acrylic fiber and polyester fiber, the top and bottom of the base layer 1 are provided with a PU layer 2, the top of the PU layer 2 is provided with a PVC layer 3, the PU layer 2 and the The thickness of the PVC layer 3 is 0.1-0.3mm, and the thickness of the base layer 1 is 0.3-0.5mm.

[0041]A method for manufacturing a novel PU and PVC mixed artificial leather, comprising the following steps: step a: through solid conveying, compacting, melting, shear mixing and extruding molding of PVC material through a screw extruder, to obtain a PVC layer 3; step b : acrylic fibers and polyester fibers are made into a base layer 1 by a textile machine, and the base layer 1 is used as a base cloth, and the base layer 1 is pre-wetted ...

Embodiment 3

[0044] In embodiment 2, add following steps again:

[0045] The melting temperature of the screw extruder in step a is 170-200°C, and the melting time is 1-2h.

[0046] A new PU and PVC mixed artificial leather, comprising a base layer 1, the base layer 1 includes acrylic fiber and polyester fiber, the top and bottom of the base layer 1 are provided with a PU layer 2, the top of the PU layer 2 is provided with a PVC layer 3, the PU layer 2 and the The thickness of the PVC layer 3 is 0.1-0.3mm, and the thickness of the base layer 1 is 0.3-0.5mm.

[0047] A method for manufacturing a novel PU and PVC mixed artificial leather, comprising the following steps: step a: through solid conveying, compacting, melting, shear mixing and extruding molding of PVC material through a screw extruder, to obtain a PVC layer 3; step b : acrylic fibers and polyester fibers are made into a base layer 1 by a textile machine, and the base layer 1 is used as a base cloth, and the base layer 1 is pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com