Method for producing household paper with high proportion sugarcane pulp

A technology of household paper and sugarcane pulp, which is applied in the field of papermaking, can solve problems such as non-standard technical indicators, insufficient satisfaction, and different process technologies, and achieve the effects of improving the quality of paper, increasing production capacity, and improving dehydration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

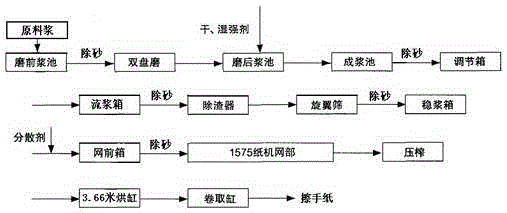

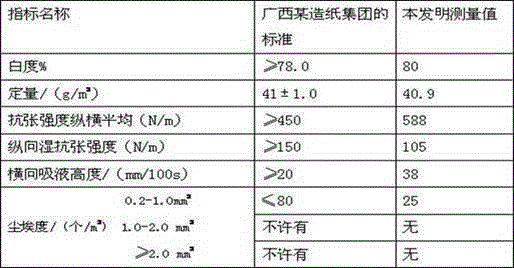

[0040] The weight content of sugarcane pulp: wood pulp is 75:25, and five desanding processes are adopted. (1) A large-hole gauze is installed in front of the pulp washing box to remove coarse sand; (2) Desanding is installed before refining (3) Set a medium-hole gauze after refining; (4) Set a grit settling plate before entering the pulp box; (5) Set a small-hole gauze at the lower part of the headbox of the paper machine net, to remove fine sand; and then use a 3.66-meter fourdrinier large-diameter double-cylinder papermaking temperature is easy to control, which can improve product quality. Use the HTDQ-N type pulp concentration automatic measuring and controlling instrument to measure the concentration of paper before and after different equipment. After the measurement and control, the pulp concentration is adjusted in time to ensure that the flow rate and sizing of each part are uniform, and then the flexible fiber-separating broom is used to make the pulp to a certain e...

Embodiment 2

[0042] The weight content of sugarcane pulp: wood pulp is 80:20, and five desanding processes are adopted. (1) A large-hole gauze is installed in front of the pulp washing box to remove coarse sand; (2) Desanding is installed before refining (3) Set a medium-hole gauze after refining; (4) Set a grit settling plate before entering the pulp box; (5) Set a small-hole gauze at the lower part of the headbox of the paper machine net, to remove fine sand; and then use a 3.66-meter fourdrinier large-diameter double-cylinder papermaking temperature is easy to control, which can improve product quality. Use the HTDQ-N type pulp concentration automatic measuring and controlling instrument to measure the concentration of paper before and after different equipment. After the measurement and control, adjust the pulp concentration in time to ensure that the flow rate and sizing of each part are uniform, and then use a flexible fiber splitting broom to make the fibers have a certain degree of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com