A kind of non-woven water transfer paper and preparation method thereof

A technology of water transfer printing paper and non-woven fabrics, which is applied in the direction of copying/marking methods, textiles and papermaking, printing, etc., and can solve the problem of high square meter weight and thickness of base paper, long preparation process of water transfer printing paper, and low product quality. Problems such as thickness and grammage, to achieve stable dimensions, improve printing quality, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

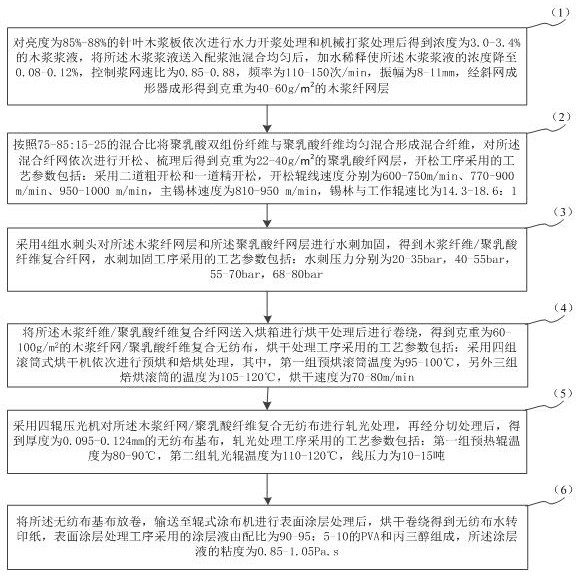

[0034] figure 1 It is a method flow chart of a method for preparing non-woven water transfer printing paper shown according to an exemplary embodiment, such as figure 1 As shown, the method includes:

[0035] Step (1): The coniferous wood pulp board with a brightness of 85%-88% is sequentially subjected to hydraulic opening treatment and mechanical beating treatment to obtain a wood pulp slurry with a concentration of 3.0-3.4%, and the wood pulp slurry is sent to the distribution After the pulp pool is evenly mixed, dilute with water to reduce the concentration of the wood pulp slurry to 0.08-0.12%, control the pulp-net speed ratio to 0.85-0.88, the frequency to 110-150 times / min, and the amplitude to 8-11mm. The weight is 40-60g / m after being formed by the net former 2 wood pulp fiber web layer.

[0036] Among them, hydraulic opening treatment can obtain wood pulp fibers with longer length, and mechanical beating treatment can further increase the subsequent entanglement p...

Embodiment 1

[0055] (1) Preparation of the wood pulp fiber web layer: after the coniferous wood pulp board with a brightness of 85% is subjected to hydraulic opening treatment and mechanical beating treatment, a wood pulp slurry with a concentration of 3.0% is obtained, and the wood pulp slurry is sent into After mixing evenly in the pulp mixing tank, dilute with water to reduce the concentration of the wood pulp slurry to 0.08%, control the pulp net speed ratio to 0.88, the frequency to 150 times / min, and the amplitude to 11mm, and form it with an inclined wire former to obtain the grammage 40g / m 2 The wood pulp fiber web layer, wherein, the hydraulic opening treatment process comprises: carry out hydraulic opening treatment pulverization to described coniferous wood pulp board and obtain wood pulp slurry, the length of wood pulp fiber in the described wood pulp slurry is 5mm, and width is 60.8 μm, the pulping concentration is controlled to be 3.0% during the hydraulic pulping process, an...

Embodiment 2

[0063] (1) Preparation of the wood pulp fiber web layer: after the coniferous wood pulp board with a brightness of 87% is subjected to hydraulic opening treatment and mechanical beating treatment, a wood pulp slurry with a concentration of 3.2% is obtained, and the wood pulp slurry is sent into After mixing evenly in the pulp mixing tank, dilute with water to reduce the concentration of the wood pulp slurry to 0.10%, control the pulp net speed ratio to 0.86, the frequency to 130 times / min, and the amplitude to 10 mm, and form it with an inclined wire former to obtain the grammage 50g / m 2 The wood pulp fiber web layer, wherein, the hydraulic opening treatment process comprises: carry out hydraulic opening treatment pulverization to described coniferous wood pulp board and obtain wood pulp slurry, the length of wood pulp fiber in the described wood pulp slurry is 3mm, width is 52.1 μm, the pulping concentration is controlled to be 3.2% during the hydraulic pulping process, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com