Rare earth treatment device

A processing device and rare earth technology, applied in the direction of electrolysis process, surface etching composition, electrolysis components, etc., can solve the problems of excessive electric energy, increase of production cost, failure to recycle fluorine gas, etc., and achieve the goal of reducing efficiency and increasing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

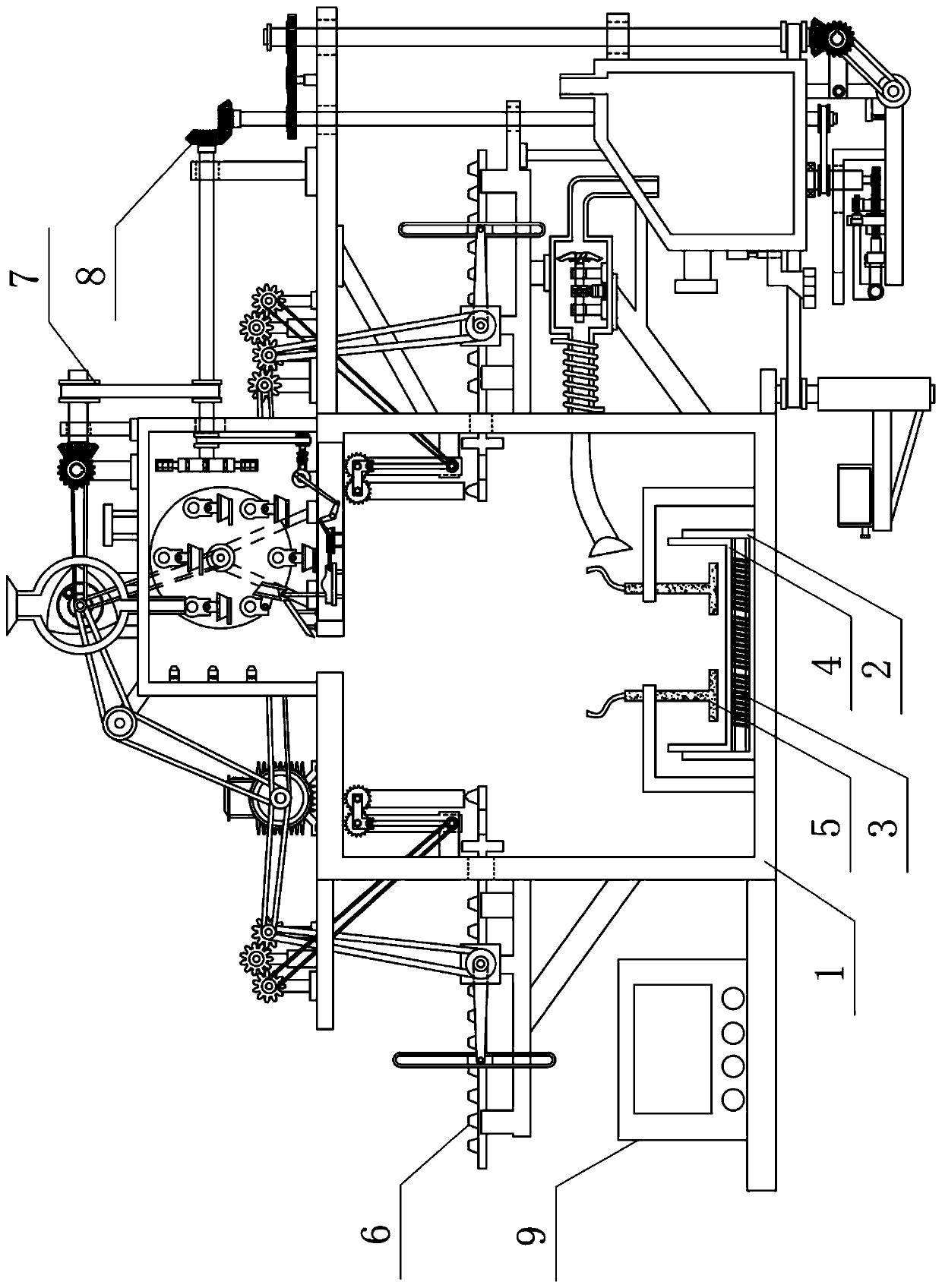

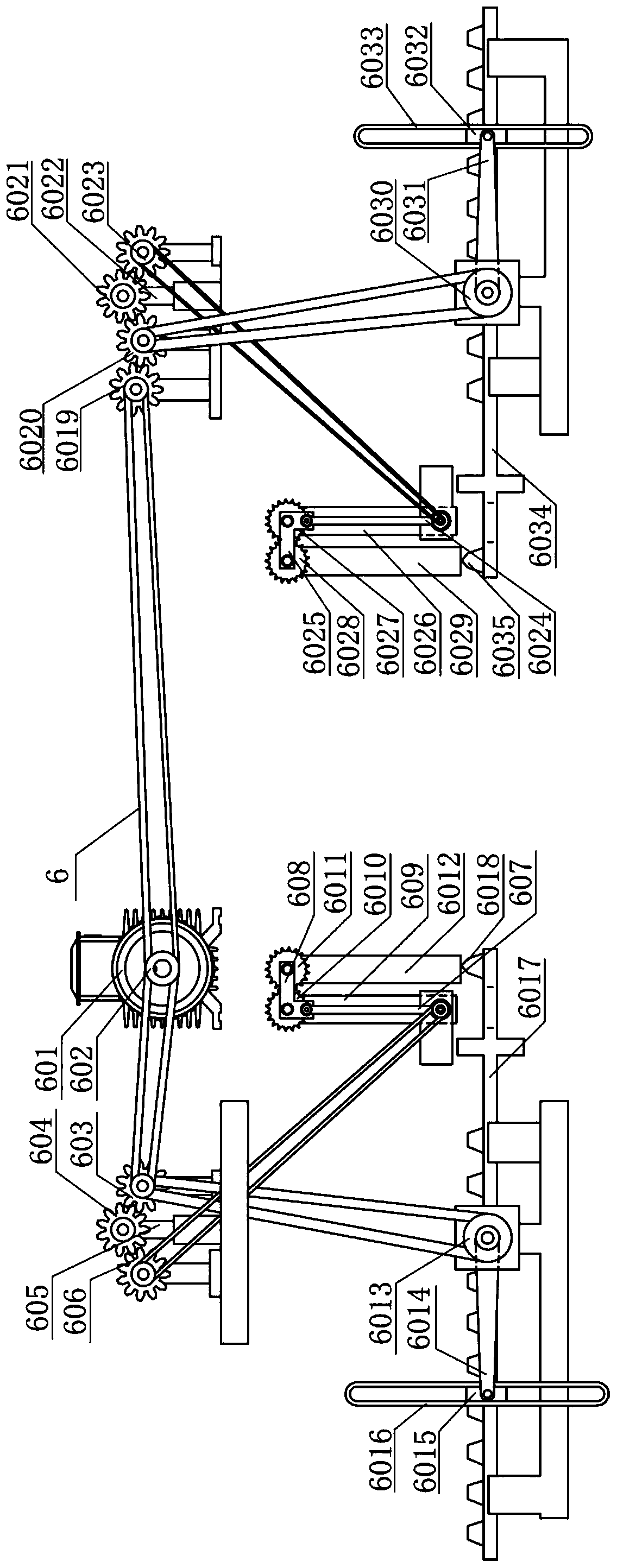

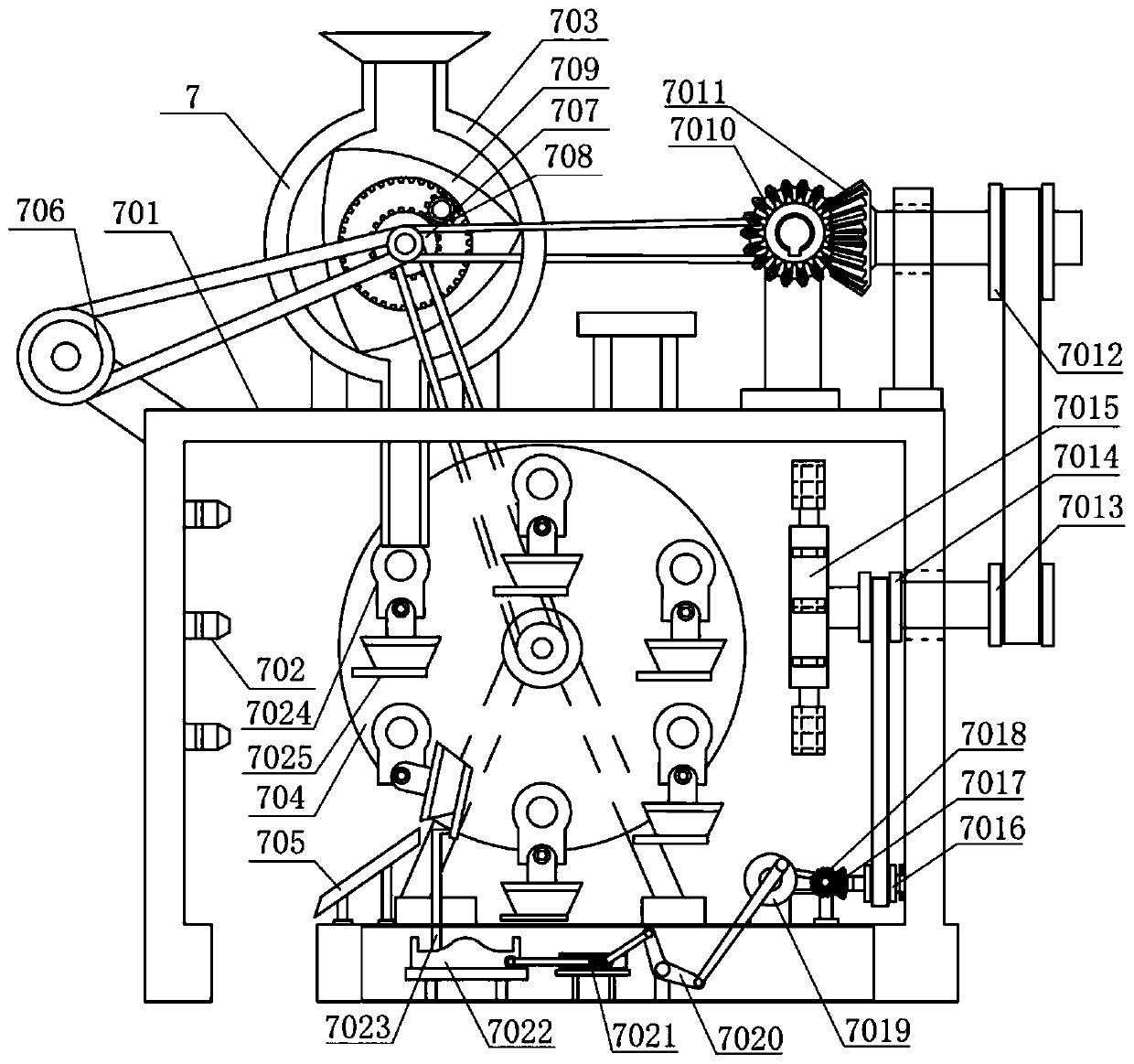

[0025] A rare earth processing device, such as Figure 1-6 As shown, it includes electrolysis chamber 1, heat insulation crucible 2, heating wire 3, electrolysis crucible 4, electrode 5, condensation separation device 6, high temperature purification device 7, fluorine gas recovery device 8 and control panel 9; the middle part of the inner bottom of electrolysis chamber 1 It is connected with the heat-insulated crucible 2; the left top of the electrolysis chamber 1 is provided with a condensation separation device 6; the top of the electrolysis chamber 1 is provided with a high-temperature purification device 7, and the left end of the high-temperature purification device 7 is connected with the condensation separation device 6; There is a fluorine gas recovery device 8, and the top of the fluorine gas recovery device 8 is connected to the high-temperature purification device 7; the left bottom of the electrolysis chamber 1 is provided with a control panel 9; the middle part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com