Shallow layer low-temperature oil deposit microfoam temporary plugging agent and preparation method thereof

A technology of low-temperature oil and temporary plugging agent, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor adaptability, poor environmental performance, and high cost of low-permeability reservoirs, and achieve weak plugging ability, Strong compressive strength and good injection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

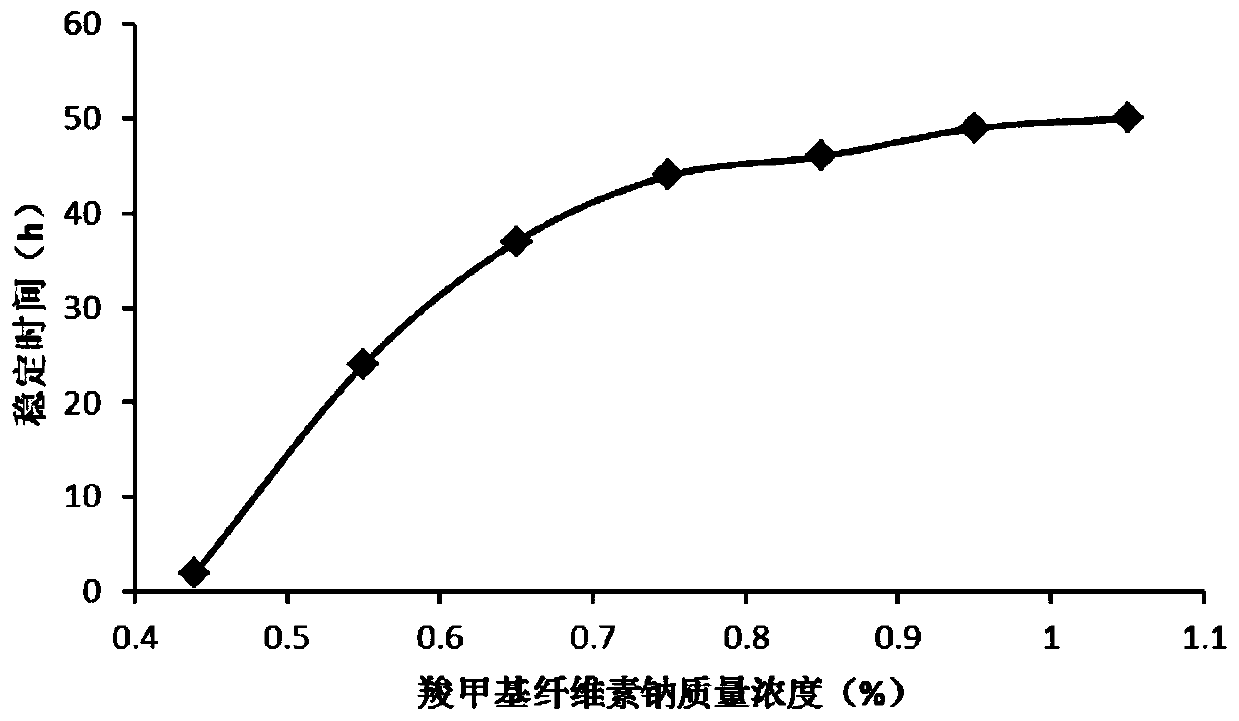

[0051] Through the comparative test and evaluation of several components in the micro-foam temporary plugging agent for shallow low-temperature reservoirs, the ratio of the micro-foam temporary plugging agent for shallow low-temperature reservoirs is determined to be 200 parts NaHCO 3Water type, formation water with a salinity of 5700mg / L; 0.5 parts of sodium dimethyl-hexadecylbenzene sulfonate; 1.8 parts of sodium carboxymethylcellulose with a degree of substitution of 0.9; 1.6 parts of soluble starch.

[0052] Step 1) Move 200 parts of formation water into a beaker, heat the formation water in the beaker to the target formation temperature through a constant temperature water bath, add 0.5 parts of sodium cetylbenzenesulfonate, and stir until sodium cetylbenzenesulfonate Completely dissolve to obtain solution A; step 2) add 1.8 parts of sodium carboxymethylcellulose to the solution A obtained in step 1), and stir until sodium carboxymethylcellulose is completely dissolved to ...

specific Embodiment 2

[0072] Through the comparative test and evaluation of several components in the micro-foam temporary plugging agent for shallow low-temperature reservoirs, the ratio of the micro-foam temporary plugging agent for shallow low-temperature reservoirs is determined to be 200 parts NaHCO 3 Water type, formation water with a salinity of 4000mg / L; 0.4 parts of sodium dimethyl-hexadecylbenzene sulfonate; 1.5 parts of sodium carboxymethylcellulose with a degree of substitution of 0.5; 1.0 parts of soluble starch. Step 1) Move 200 parts of formation water into a beaker, heat the formation water in the beaker to the target formation temperature through a constant temperature water bath, add 0.4 parts of sodium cetylbenzenesulfonate, and stir until sodium cetylbenzenesulfonate Completely dissolve to obtain solution A; step 2) add 1.5 parts of sodium carboxymethylcellulose to solution A obtained in step 1), and stir until sodium carboxymethylcellulose is completely dissolved to obtain solut...

specific Embodiment 3

[0092] Through the comparative test and evaluation of several components in the micro-foam temporary plugging agent for shallow low-temperature reservoirs, the ratio of the micro-foam temporary plugging agent for shallow low-temperature reservoirs is determined to be 200 parts NaHCO 3 Water type, formation water with a salinity of 7000mg / L; 0.6 parts of sodium dimethyl-hexadecylbenzene sulfonate; 2.0 parts of sodium carboxymethylcellulose with a degree of substitution of 1.2; 2.0 parts of soluble starch. Step 1) Move 200 parts of formation water into a beaker, heat the formation water in the beaker to the target formation temperature through a constant temperature water bath, add 0.4 parts of sodium cetylbenzenesulfonate, and stir until sodium cetylbenzenesulfonate Completely dissolve to obtain solution A; step 2) add 2.0 parts of sodium carboxymethylcellulose to the solution A obtained in step 1), and stir until sodium carboxymethylcellulose is completely dissolved to obtain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com