The chemical synthesis method of 3-chloro-1-propanol

A technology for chemical synthesis and propanol, applied in chemical instruments and methods, organic chemistry, chemical recycling, etc., can solve problems such as large pressure changes, high equipment requirements, and many gas raw materials, achieving low risk, low industrialization difficulty, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

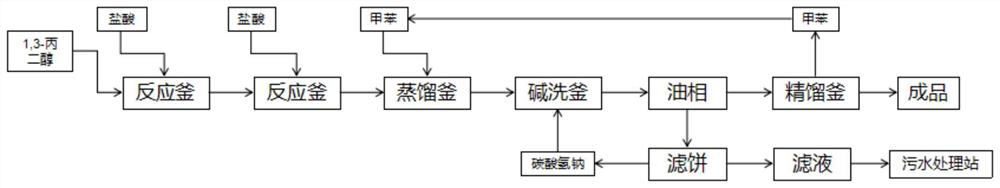

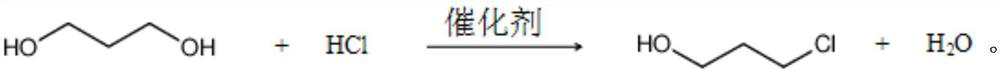

[0031] like figure 1 Shown, the chemical synthesis method of described 3-chloro-1-propanol, specifically comprises the following steps:

[0032] (1) 440kg 1,3-propanediol, 600kg hydrochloric acid, 3kg of benzenesulfonic acid are dropped into the 2000L glass-lined still with stirring and reflux condensing device, and stirring is warming up to 90 ℃, insulation reaction;

[0033] (2) after being incubated for 3 hours, reduce the temperature of the still to 50 ° C, drop 460kg of hydrochloric acid into the still, continue to be warming up to 90 ° C and be incubated for 10 hours, reduce the temperature of the still for sampling GC analysis, when 3-chloro-1-propanol When the content of toluene reaches 80%, the feed liquid is pushed into the still, and 150kg of toluene is thrown into the still to carry out the heating and refluxing reaction with water;

[0034] (3) lower the temperature of the still to room temperature after the reaction with water, add sodium bicarbonate and neutral...

Embodiment 2

[0038] like figure 1 Shown, the chemical synthesis method of described 3-chloro-1-propanol, specifically comprises the following steps:

[0039] (1) 440kg 1,3-propanediol, 600kg hydrochloric acid, 3kg of benzenesulfonic acid are dropped into the 2000L glass-lined still with stirring and reflux condensing device, and stirring is warming up to 90 ℃, insulation reaction;

[0040] (2) after being incubated for 3 hours, reduce the temperature of the still to 50 ° C, drop 460kg of hydrochloric acid into the still, continue to be warming up to 90 ° C and be incubated for 10 hours, reduce the temperature of the still for sampling GC analysis, when 3-chloro-1-propanol When the content reached 75%, the feed liquid was pushed into the still, and 150kg of toluene was thrown into the still to carry out the heating and refluxing reaction with water;

[0041] (3) lower the temperature of the still to room temperature after the reaction with water, add sodium bicarbonate and neutralize the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com