Chemical synthesis method of 3-chloro-1-propanol

A technology for chemical synthesis and propanol, applied in chemical instruments and methods, organic chemistry, chemical recycling, etc., can solve the problems of many gas raw materials, high equipment requirements, low reaction yield, etc., achieve low industrialization difficulty, improve efficiency, The effect of easy participation in the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

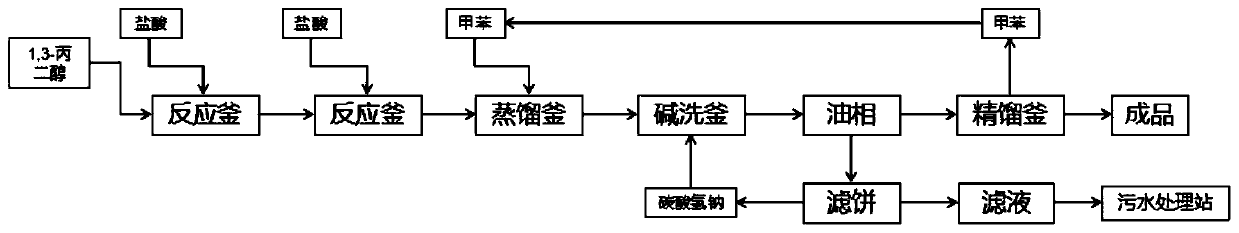

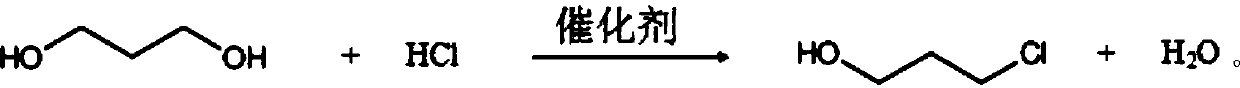

[0031] Such as figure 1 Shown, the chemical synthesis method of described 3-chloro-1-propanol specifically comprises the following steps:

[0032] (1) First put 440kg of 1,3-propanediol, 600kg of hydrochloric acid, and 3kg of benzenesulfonic acid into a 2000L glass-lined kettle with stirring and reflux condensation device, stir and heat up to 90°C, and keep warm for reaction;

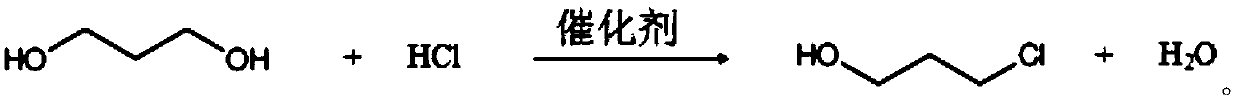

[0033] (2) After 3 hours of heat preservation, lower the temperature of the kettle to 50°C, then put 460kg of hydrochloric acid into the kettle, continue to heat up to 90°C and keep it warm for 10 hours, then lower the temperature of the kettle and take samples for GC analysis. When 3-chloro-1-propanol When the content of toluene reached 80%, the feed liquid was squeezed into the still, and 150kg of toluene was thrown into the still to carry out the reaction of heating and reflux with water;

[0034] (3) After the reaction with water is completed, the temperature of the kettle is lowered to room temper...

Embodiment 2

[0038] Such as figure 1 Shown, the chemical synthesis method of described 3-chloro-1-propanol specifically comprises the following steps:

[0039] (1) First put 440kg of 1,3-propanediol, 600kg of hydrochloric acid, and 3kg of benzenesulfonic acid into a 2000L glass-lined kettle with stirring and reflux condensation device, stir and heat up to 90°C, and keep warm for reaction;

[0040] (2) After 3 hours of heat preservation, lower the temperature of the kettle to 50°C, then put 460kg of hydrochloric acid into the kettle, continue to heat up to 90°C and keep it warm for 10 hours, then lower the temperature of the kettle and take samples for GC analysis. When 3-chloro-1-propanol When the content of toluene reached 75%, the feed liquid was squeezed into the still, and 150kg of toluene was thrown into the still to carry out the reaction of heating and reflux with water;

[0041] (3) After the reaction with water is completed, the temperature of the kettle is lowered to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com