Biological organic fertilizer applied to greenhouse vegetables

A bio-organic fertilizer and vegetable technology, applied in the application, nitrogen fertilizer, cyanamide fertilizer, etc., can solve the problems of long stacking time of products, difficulty in controlling the amount of application, corrosion of equipment, etc., so as to facilitate quantitative manure application and increase The production workload and the effect of ensuring the strength of the packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

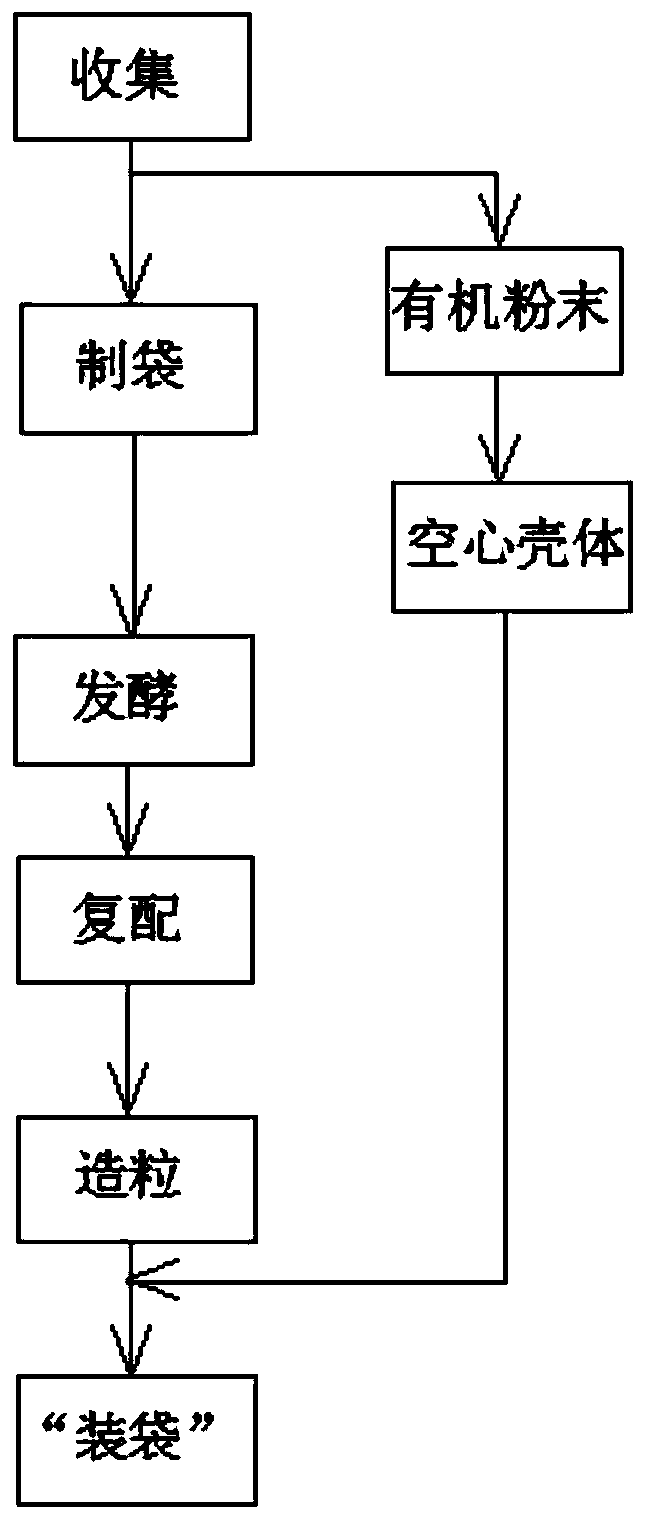

[0056] see image 3 , a bio-organic fertilizer applied to greenhouse vegetables, comprising the following preparation steps:

[0057] S1. Collect

[0058] Collect chicken manure and chicken feathers separately ("chicken feathers" are not limited to chicken feathers, and may include one or more of chicken feathers, duck feathers, and goose feathers. Similarly, "chicken manure" is not limited to chicken manure, but may include chicken manure, duck manure and one or more of goose droppings), spare;

[0059] S2, bag making

[0060] The chicken feathers are cleaned and disinfected, and after drying, the soft part is woven into a bag-shaped "chicken feather bag 3", and the remaining hard part is used for later use (the hard part is crushed and ground by crushing equipment and grinding equipment to obtain organic powder, hard The quality part is the part where the chicken feathers are removed and the soft hairs are removed. It can be crushed and ground into powder and can be used ...

Embodiment 2

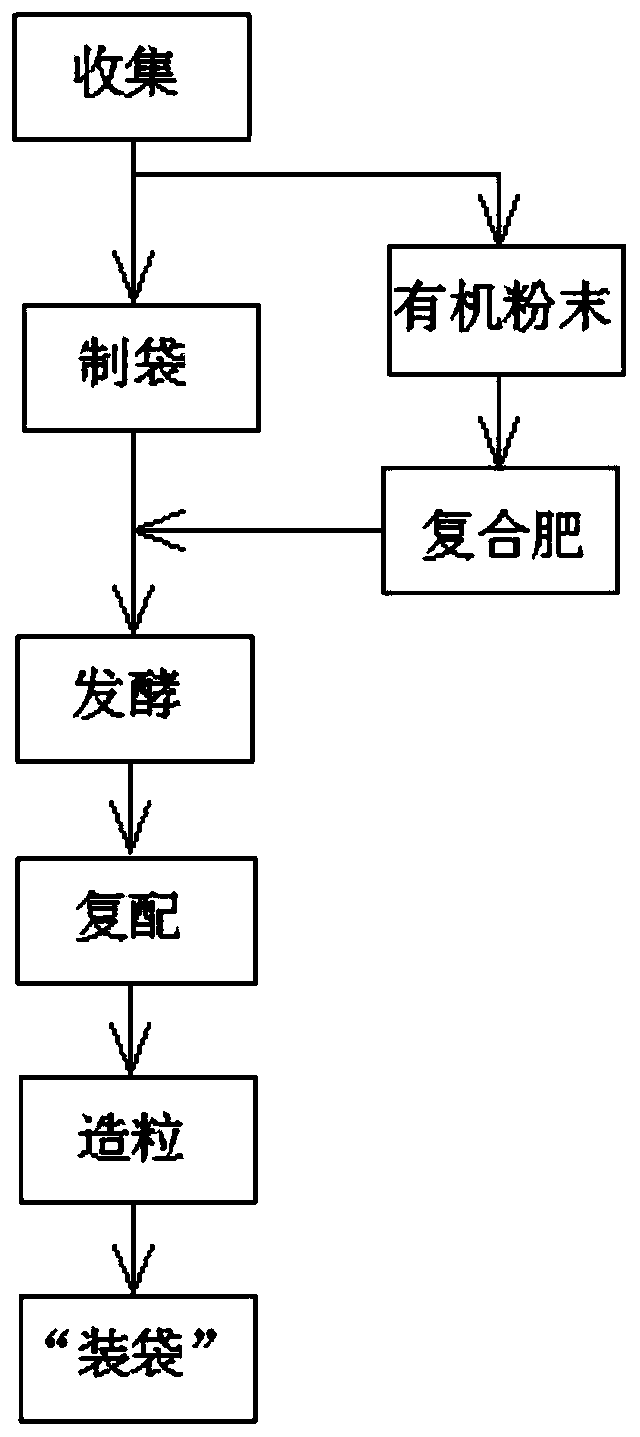

[0072] see figure 2 , a bio-organic fertilizer applied to greenhouse vegetables, comprising the following preparation steps:

[0073] S1. Collect

[0074] Collect chicken manure and chicken feathers separately ("chicken feathers" are not limited to chicken feathers, and may include one or more of chicken feathers, duck feathers, and goose feathers. Similarly, "chicken manure" is not limited to chicken manure, but may include chicken manure, duck manure and one or more of goose droppings), spare;

[0075] S2, bag making

[0076] The chicken feathers are cleaned and disinfected, and after drying, the soft part is woven into a bag-shaped "chicken feather bag 3", and the remaining hard part is used for later use (the hard part is crushed and ground by crushing equipment and grinding equipment to obtain organic powder, hard The quality part is the part where the chicken feathers are removed and the soft hairs are removed. It can be crushed and ground into powder and can be used...

Embodiment 3

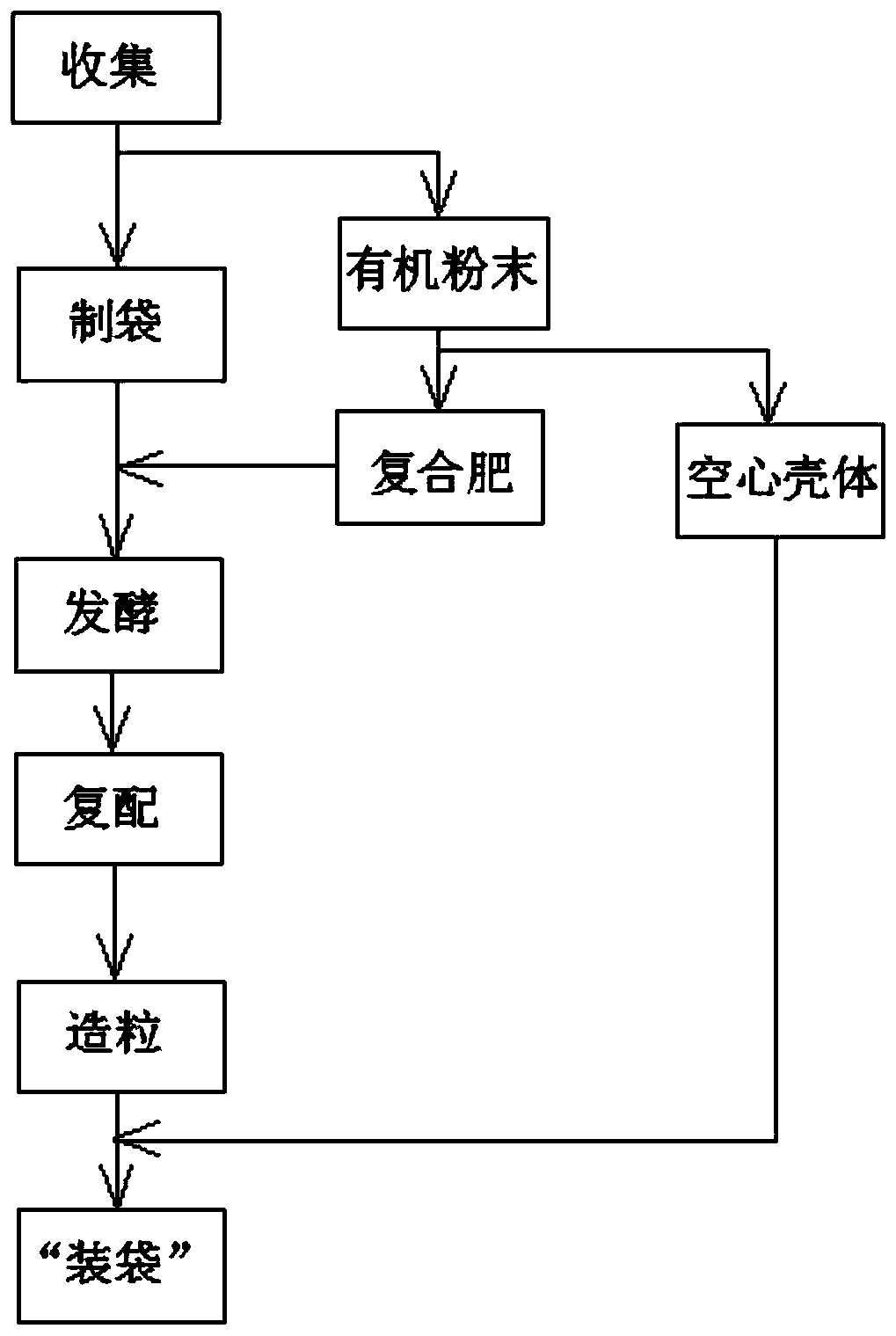

[0088] see figure 1 , a bio-organic fertilizer applied to greenhouse vegetables, comprising the following preparation steps:

[0089] S1. Collect

[0090] Collect chicken manure and chicken feathers separately ("chicken feathers" are not limited to chicken feathers, and may include one or more of chicken feathers, duck feathers, and goose feathers. Similarly, "chicken manure" is not limited to chicken manure, but may include chicken manure, duck manure and one or more of goose droppings), spare;

[0091] S2, bag making

[0092] The chicken feathers are cleaned and disinfected, and after drying, the soft part is woven into a bag-shaped "chicken feather bag 3", and the remaining hard part is used for later use (the hard part is crushed and ground by crushing equipment and grinding equipment to obtain organic powder, hard The quality part is the part where the chicken feathers are removed and the soft hairs are removed. It can be crushed and ground into powder and can be used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com