Steel slag pulverization and carbon fixation treatment system and application thereof

A carbon treatment and steel slag technology, applied in the field of steel slag crushing and carbon fixation treatment system, can solve the problems of insufficient dissociation of "steel" and "slag", complicated and inefficient steel slag crushing process, and short service life of wear-resistant parts , to achieve significant energy saving effect, improve carbon fixation efficiency, and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

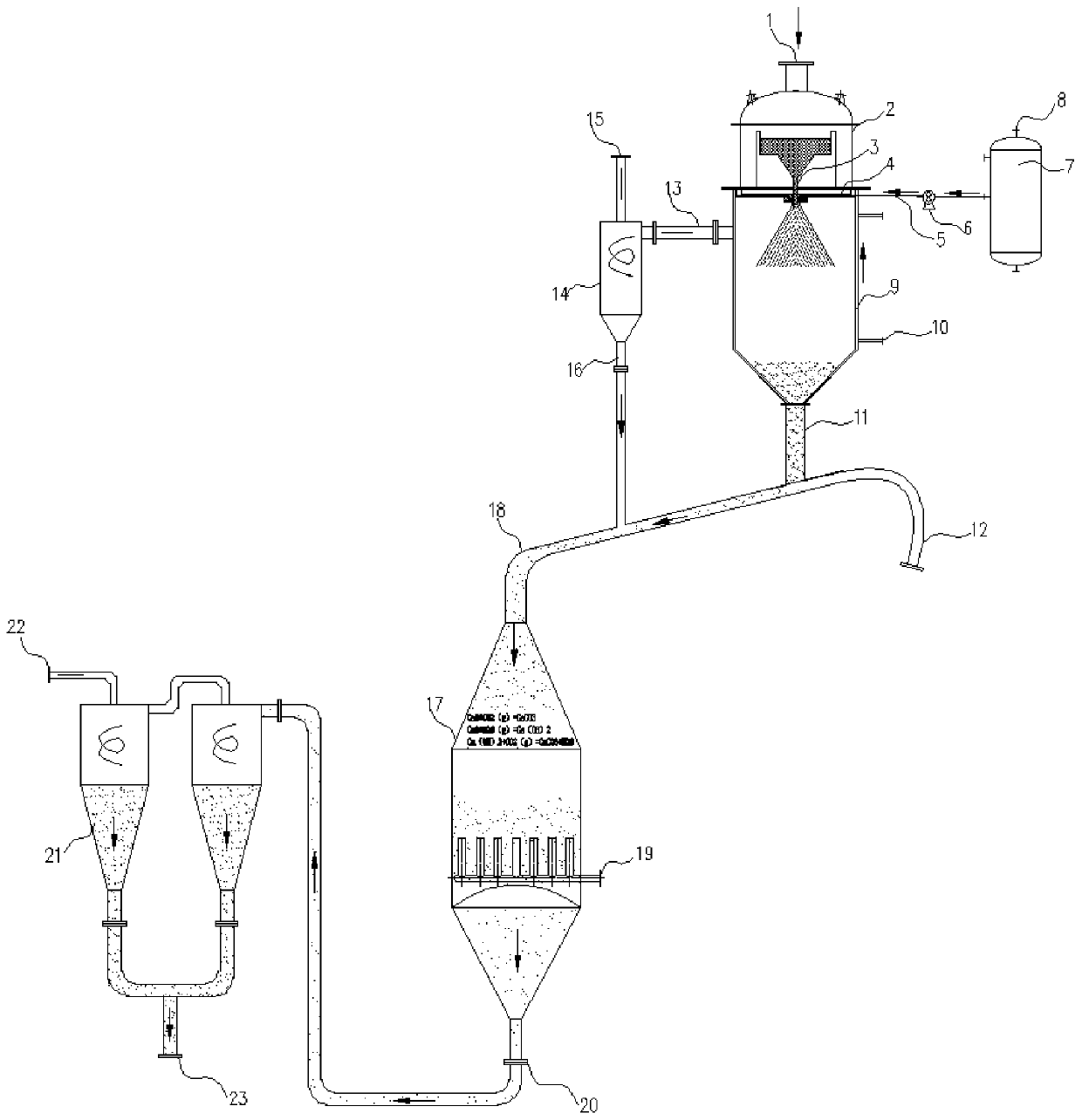

[0036] refer to figure 1 , a steel slag crushing and carbon fixation treatment system, comprising: a steel slag buffer system, a steel slag crushing chamber, a high-pressure atomization system, an atomized gas dedusting system, a carbon fixation stabilization system, and a powder slag collection and capture system; wherein:

[0037] The steel slag buffer system includes: a steel slag inlet 1, a molten steel slag chamber 2, and a slag chamber outlet 3; . The molten steel slag enters the molten steel slag chamber from the steel slag feed port for buffering. The molten steel slag chamber has the functions of heating and heat preservation. The buffered molten steel slag enters the crushing chamber through the outlet of the slag chamber.

[0038] The steel slag crushing chamber 9 is connected to the outlet 3 of the slag crushing chamber, and the steel slag crushing chamber 9 is provided with a circulating cooling water inlet and outlet 10; the lower end of the steel slag crushing ...

Embodiment 2

[0048] A steel slag crushing and carbon fixation treatment system is the same as that in Embodiment 1, the difference is that: as a further technical solution, the steel slag crushing and carbon fixation treatment system also includes a waste heat recovery system. The waste heat recovery system includes a jacket cooler, pipeline, gas preheater, etc. The separated gas of carbon dioxide and water vapor from the separator enters the waste heat recovery system, and the water vapor generated by waste heat recovery continues to be preheated and then enters the fluidized bed for reaction device.

Embodiment 3

[0050] A steel slag crushing and carbon fixation treatment system is the same as that in Embodiment 1, except that: the fluidized bed reactor 17 is provided with a steel slag powder and superheated steam mixing device, so as to improve the carbon fixation reaction efficiency of the fluidized bed reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com