Double-layer DMF chip rapidly prepared based on polymer composite film and preparation method

A composite membrane and polymer technology, applied in the field of microfluidics, can solve the problems of complex steps, surface grooves of the dielectric layer and hydrophobic layer, affecting the stability of droplet movement, etc., and achieves reduced manufacturing costs, simplified chip manufacturing steps, The effect of reducing the cost of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing of description, the present invention is described further, but the present invention is not limited to following examples.

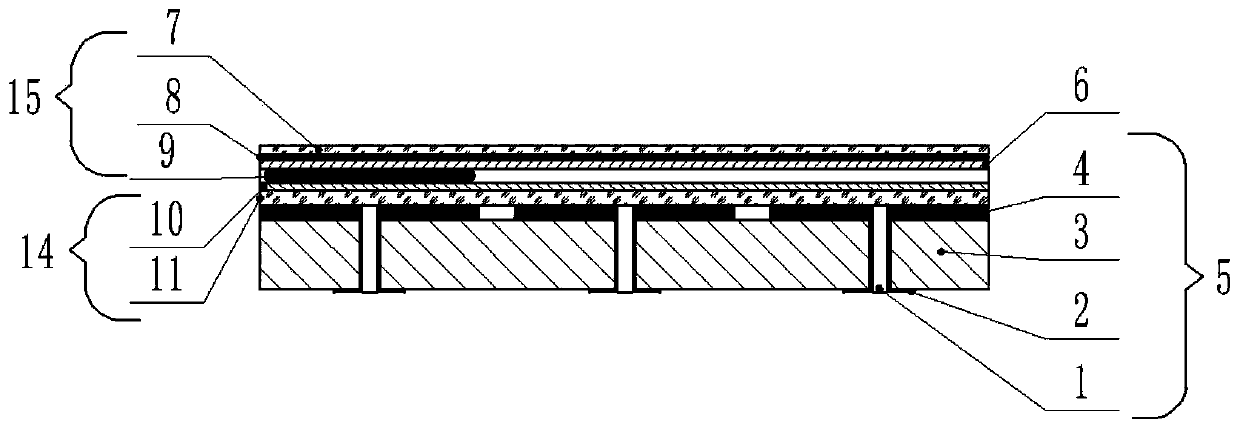

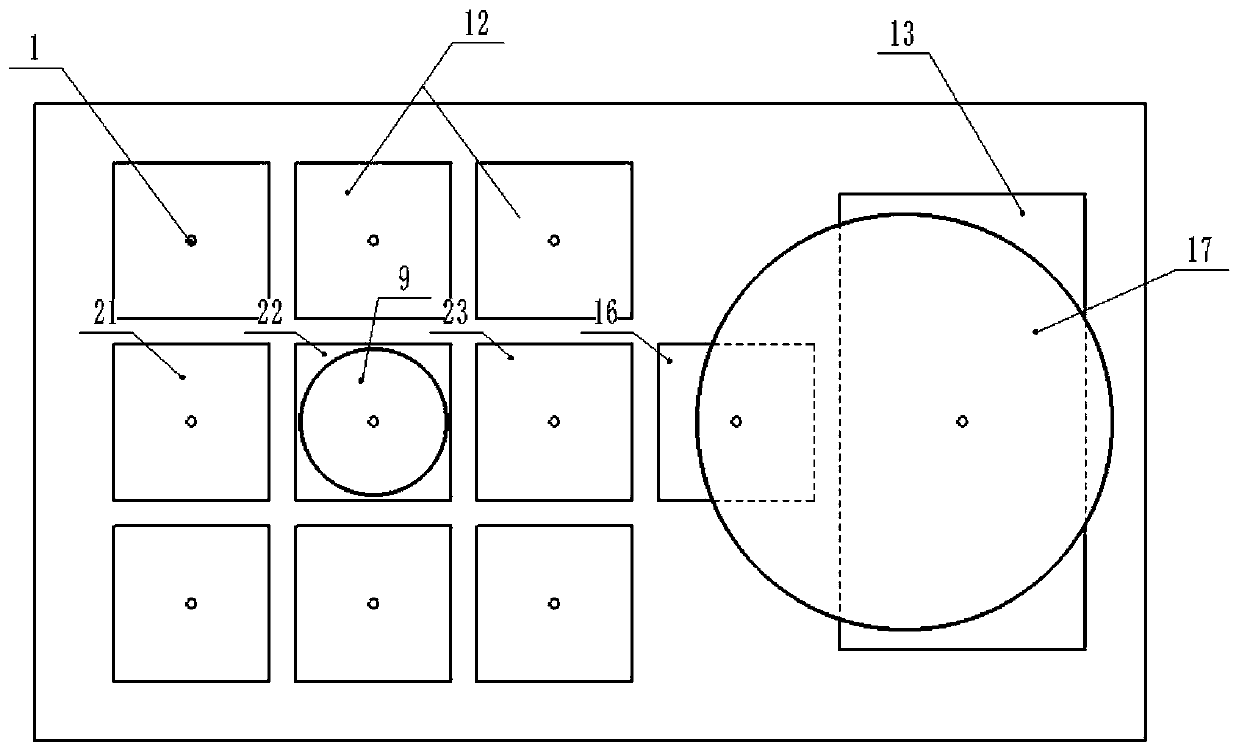

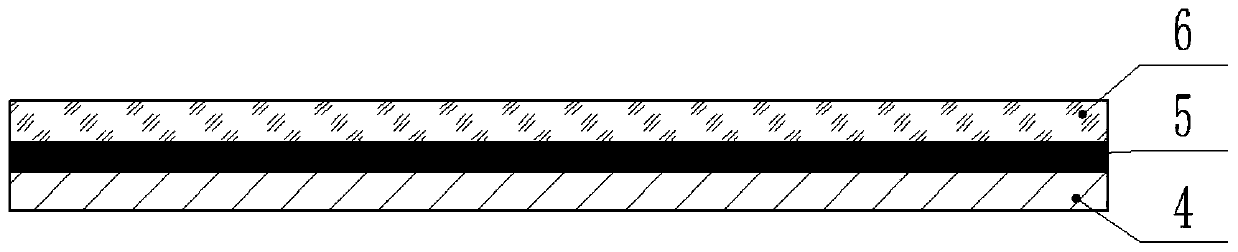

[0039] Such as figure 1 As shown, including the lower pole plate 5 and the upper pole plate 15, such as image 3 As shown, the upper pole plate 15 is mainly composed of the upper pole plate hydrophobic layer 6, the upper pole plate substrate 7 and the upper pole plate conductive layer 8 sequentially stacked from bottom to top; The electrode array layer, the large electrode layer, the dielectric layer 11 and the lower plate hydrophobic layer 10, the dielectric layer 11 includes a polymer composite film substrate layer and a polymer composite film adhesive layer that are stacked from top to bottom; The electrical layer 11 and the hydrophobic layer 10 of the lower plate are sequentially arranged on the electrode layer, and the dielectric layer 11 is located between the hydrophobic layer 10 of the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com