Modified CHA molecular sieve and preparation method and application thereof

A molecular sieve and modification technology, which is applied in the direction of separation methods, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reducing pore volume, catalyst deactivation, hindering the contact between reactants and active centers, etc., and achieve high pore volume, increase Effect of large pore volume and specific surface area, high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 H-SSZ-13 molecular sieves A1, A2, A3, A4, A5, A6 and A7 (H-CHA molecular sieves before modification)

[0078] Add 126.0g of 25% N,N,N-trimethylamantadine hydroxide to 23.5g of deionized water, mix well, then add 3.1g of sodium hydroxide to it, stir until fully dissolved, then 5.3g of hydroxide Aluminum (Al 2 o 3 The content is 65%), mix well, and finally add 150.0g of silica sol (SiO 2 content of 30%), fully stirred for 2h to obtain the primary mixture. Wherein, the Al in the primary mixture 2 o 3 , SiO 2 , N,N,N-Trimethylamantadine Hydroxide, OH - and H 2 The molar ratio of O is 1:22.21:4.45:6.70:366.42. The above mixture was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a 170 °C oven for crystallization for 48 hours, taken out, quenched, and the crystallized product was subjected to solid-liquid separation, washing and drying to obtain Na- SSZ-13 molecular sieve (initial molecular sieve).

[0079] Am...

Embodiment 2

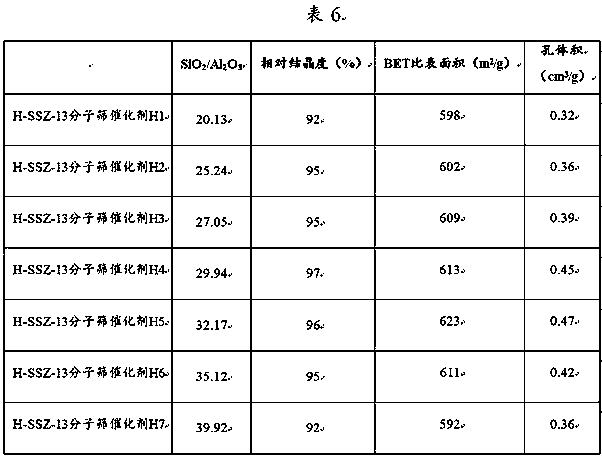

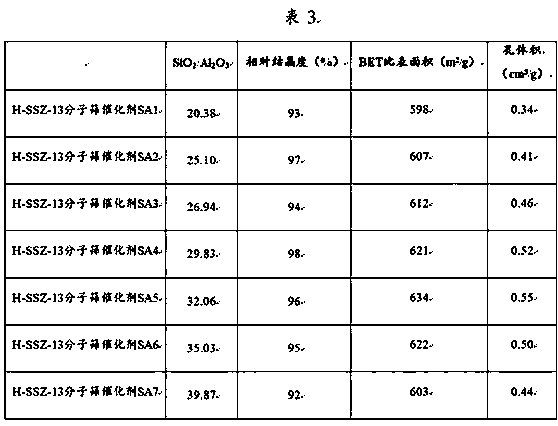

[0081]Example 2 H-SSZ-13 molecular sieves CA1, CA2, CA3, CA4, CA5, CA6 and CA7

[0082] The H-SSZ-13 molecular sieves A1, A2, A3, A4, A5, A6 and A7 prepared in Example 1 were subjected to acid treatment. where SiO 2 / Al 2 o 3 H-SSZ-13 molecular sieves A1-A4 less than 30 are divided into the first group, SiO 2 / Al 2 o 3 H-SSZ-13 molecular sieves A5-A7 larger than 30 belong to the second group.

[0083] The acid treatment conditions were the same for the first set of samples. Taking H-SSZ-13 molecular sieve A1 as an example to illustrate the acid treatment conditions of the first group of samples, add 100g of H-SSZ-13 molecular sieve A1 into 1000mL of 0.3mol / L hydrochloric acid solution and stir at 65°C for 30min, then perform solid-liquid separation , washed and dried to obtain H-SSZ-13 molecular sieve CA1, whose SiO 2 / Al 2 o 3 =20.39. The acid treatment conditions of H-SSZ-13 molecular sieves A2-A4 are the same as those of H-SSZ-13 molecular sieves A1, H-SSZ-13 mol...

Embodiment 3

[0085] Example 3 H-SSZ-13 molecular sieves DA1, DA2, DA3, DA4, DA5, DA6 and DA7 (modified CHA molecular sieves)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com