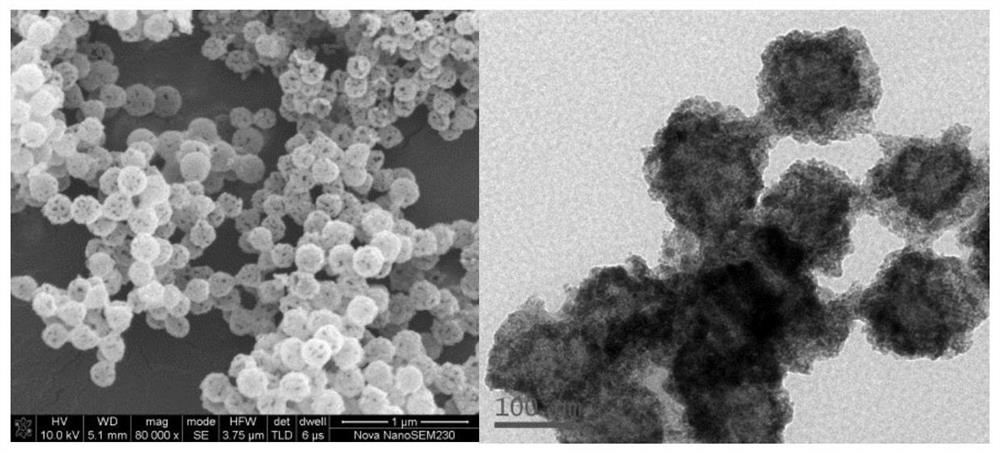

Medical double-shell porous structure hollow nanospheres and preparation method thereof

A hollow nano-porous structure technology, applied in the field of biomedical magnetic materials, can solve unseen problems, achieve uniform size, change relaxation rate and relaxation time, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of phenolic resin microspheres. Measure 200ml of deionized water, 10ml of absolute ethanol and 1ml of ammonia water into a dry 500ml three-neck flask and mix, add 1g of resorcinol, slowly add 2ml of formaldehyde solution, and stir in an oil bath at 30°C for 10h. After the reaction, the mixed solution was transferred to a high-pressure reactor, and placed in a vacuum drying oven at 80° C. for hydrothermal reaction for 22 hours for aging. Then the solid and liquid were separated, and the solid was vacuum-dried at 80° C. for 24 hours to obtain phenolic resin (PF) microspheres with a size of about 200 nm.

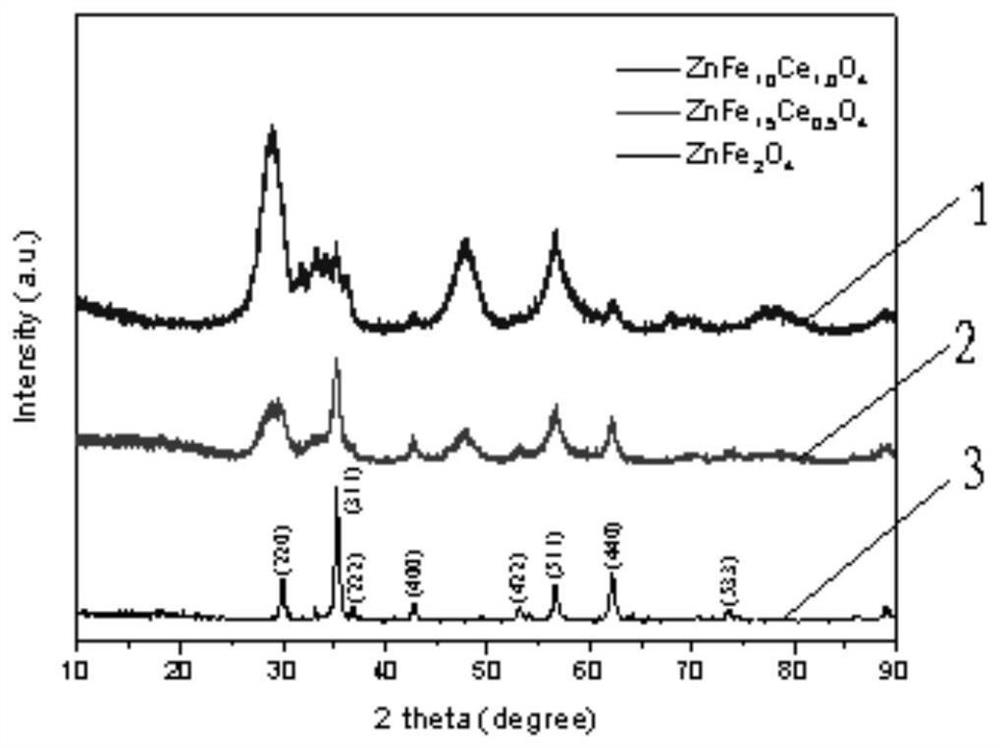

[0050] (2) Preparation of rare earth ion Ce 3+ Doped Zn(Fe,Ce) 2 o 4 Ferrite precursor solution. According to Zn(Fe,Ce) 2 o 4 Molar ratio, respectively weigh appropriate amount of nitrate, including Zn(NO 3 ) 2 , Fe(NO 3 ) 3 and Ce(NO 3 ) 3 , Put the weighed several nitrates into the beaker, and add an appropriate amount of deionized water at ...

Embodiment 2

[0059] (1) Preparation of phenolic resin microspheres. Measure 300ml of deionized water, 40ml of absolute ethanol and 10ml of ammonia water into a dry 500ml three-necked flask and mix, add 10g of resorcinol, then slowly add 6ml of formaldehyde solution to the mixed solution, and stir in an oil bath at 40°C for 12h. After the reaction, the mixed solution was transferred to a high-pressure reactor, and placed in a vacuum drying oven at 100° C. for hydrothermal reaction for 26 hours for aging. Then the solid and liquid were separated, and the solid was vacuum-dried at 80° C. for 24 hours to obtain phenolic resin (PF) microspheres with a size of about 800 nm.

[0060] (2) Preparation of rare earth ion Ce 3+ Doped Zn(Fe,Ce) 2 o 4 Ferrite precursor solution. According to Zn(Fe,Ce) 2 o 4 Molar ratio, respectively weigh appropriate amount of nitrate, including Zn(NO 3 ) 2 , Fe(NO 3 ) 3 and Ce(NO 3 ) 3 , Put the weighed several nitrates into the beaker, and add an appropria...

Embodiment 3

[0069](1) Preparation of phenolic resin microspheres. Measure 270ml of deionized water, 25ml of absolute ethanol and 5ml of ammonia water into a dry 500mL three-neck flask and mix, add 6g of resorcinol, slowly add 3ml of formaldehyde solution, and stir in an oil bath at 30°C for 12h. After the reaction, the mixed solution was transferred to a high-pressure reactor, and placed in a vacuum oven at 100° C. for hydrothermal reaction for 24 hours for aging. Separation of solid and liquid, take the solid and vacuum dry at 70°C to obtain phenolic resin (PF) microspheres with a size of about 500nm.

[0070] (2) Preparation of rare earth ion Ce 3+ Doped Zn(Fe,Ce) 2 o 4 Ferrite precursor solution. According to Zn(Fe,Ce) 2 o 4 Molar ratio, respectively weigh appropriate amount of nitrate, including Zn(NO 3 ) 2 , Fe(NO 3 ) 3 and Ce(NO 3 ) 3 , Put the weighed several nitrates into the beaker, and add an appropriate amount of deionized water at the same time, fully dissolve in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com