Method for preparing piercing-prevention clad sheet through waste fiber cut segment and inorganic particle mixing laying-up hot pressing and purpose

A technology of waste fibers and inorganic particles, which is applied to resin composite sheets for clothing and its preparation, bulletproof clothing materials, light weight, individual anti-stab cutting, high-efficiency anti-stab, cutting, and flexible fields, which can solve rigidity and Problems such as single damping, uniform structure, and low efficacy have achieved the effects of wide product use, simple preparation process, and commonly used control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

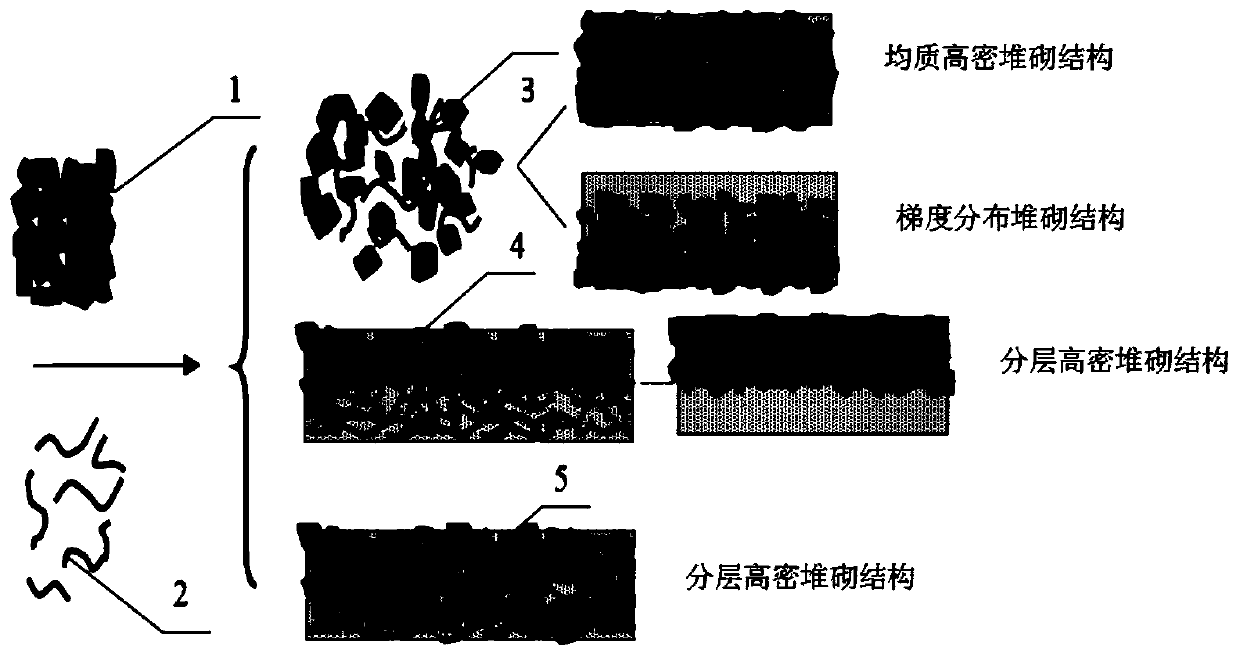

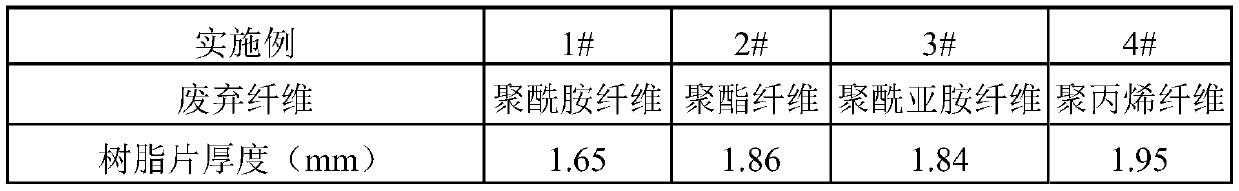

Embodiment 1

[0044] Boron carbide particles with an average particle size of 200 μm and polyamide fibers are hot-rolled and cast, and the volume fraction ratio of inorganic particles / polymers is 58:42, and a stab-resistant composite sheet is attached to the multi-layer fabric to form a multi-layer fabric. The overall square meter weight is 5.26kg / m 2 , see Table 1 for details. The puncture probability of this composite fabric is zero. If converted into the current 6.66kg / m 2 The fabric has a puncture-resistant energy of 29.4J, which is equivalent to the current conventional square meter weight (6.66kg / m 2 ), it can reduce weight by about 21.0%. It adopts a homogeneous high-density stacked structure, which belongs to a homogeneous structure. It is a stab-proof mechanism that emphasizes both the collision barrier passivation mechanism and the reverse cutting roughening mechanism, which shows that its stab-proof performance has been improved. , and can be lightweight and softened.

Embodiment 2

[0046] Artificial diamond particles with an average particle size of 30 μm and polyimide fibers are mixed and hot-rolled, and the volume fraction ratio of inorganic particles to high polymers is 25:75. The anti-stab composite sheet is attached to the multi-layer fabric, and the resulting product is multi-layered. The overall square meter weight of the layer fabric is 5.14kg / m 2 , see Table 1 for details. The puncture probability of this composite fabric is zero. If converted into the current 6.66kg / m 2 The fabric has a puncture-resistant energy of 30.5J, which is equivalent to the current conventional square meter weight (6.66kg / m 2 ), it can reduce weight by about 22.8%. It adopts a gradient distribution stacking structure, which belongs to the gradient distribution of upper sparse and lower dense. It is the main mechanism of passivation of the collision barrier during penetration. softening and softening.

Embodiment 3

[0048] Artificial diamond particles with an average particle size of 30 μm and polyimide fibers are mixed and hot-rolled, and the volume fraction ratio of inorganic particles to high polymers is 25:75. The anti-stab composite sheet is attached to the multi-layer fabric, and the resulting product is multi-layered. The overall square meter weight of the layer fabric is 5.14kg / m 2 , see Table 1 for details. The puncture probability of this composite fabric is zero. If converted into the current 6.66kg / m 2 The fabric has a puncture-resistant energy of 30.5J, which is equivalent to the current conventional square meter weight (6.66kg / m 2 ), it can reduce weight by about 22.8%. It adopts a gradient distribution stacking structure, which belongs to the gradient distribution of upper sparse and lower dense. It is the main mechanism of passivation of the collision barrier during penetration. softening and softening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com