Winding device of unwinding machine

A technology of a rewinding device and an unwinding machine, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of low safety, poor speed control ability, etc. Stability, the effect of maintaining constant tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

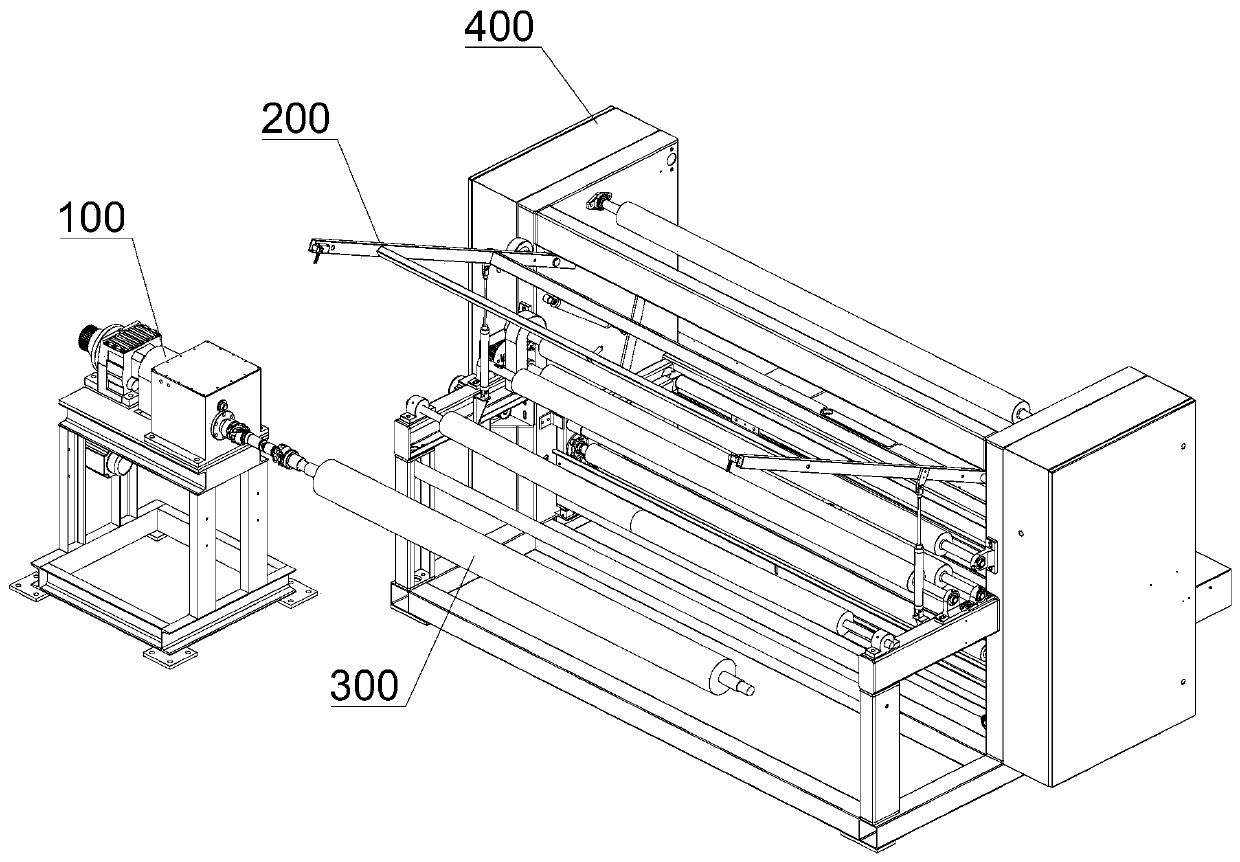

[0027] see Figures 1 to 8 As shown, this embodiment provides a winding device for an unwinder, taking the unwinder as an example, and of course it can also be applied to other machine tools. The winding device includes a winding drive mechanism 100 for driving and controlling the rotational speed, a cloth roll outer diameter detecting frame 200 and a controller.

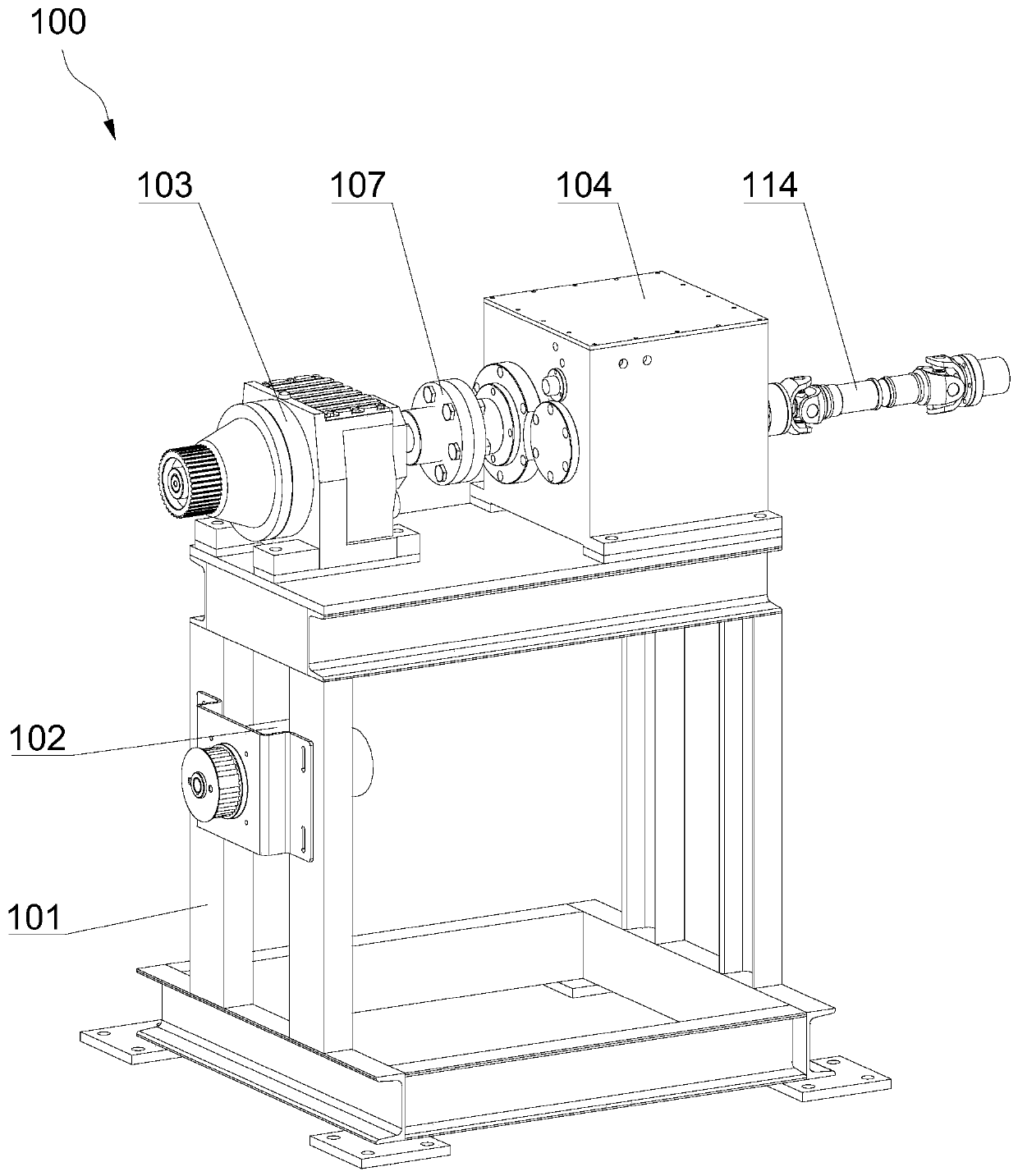

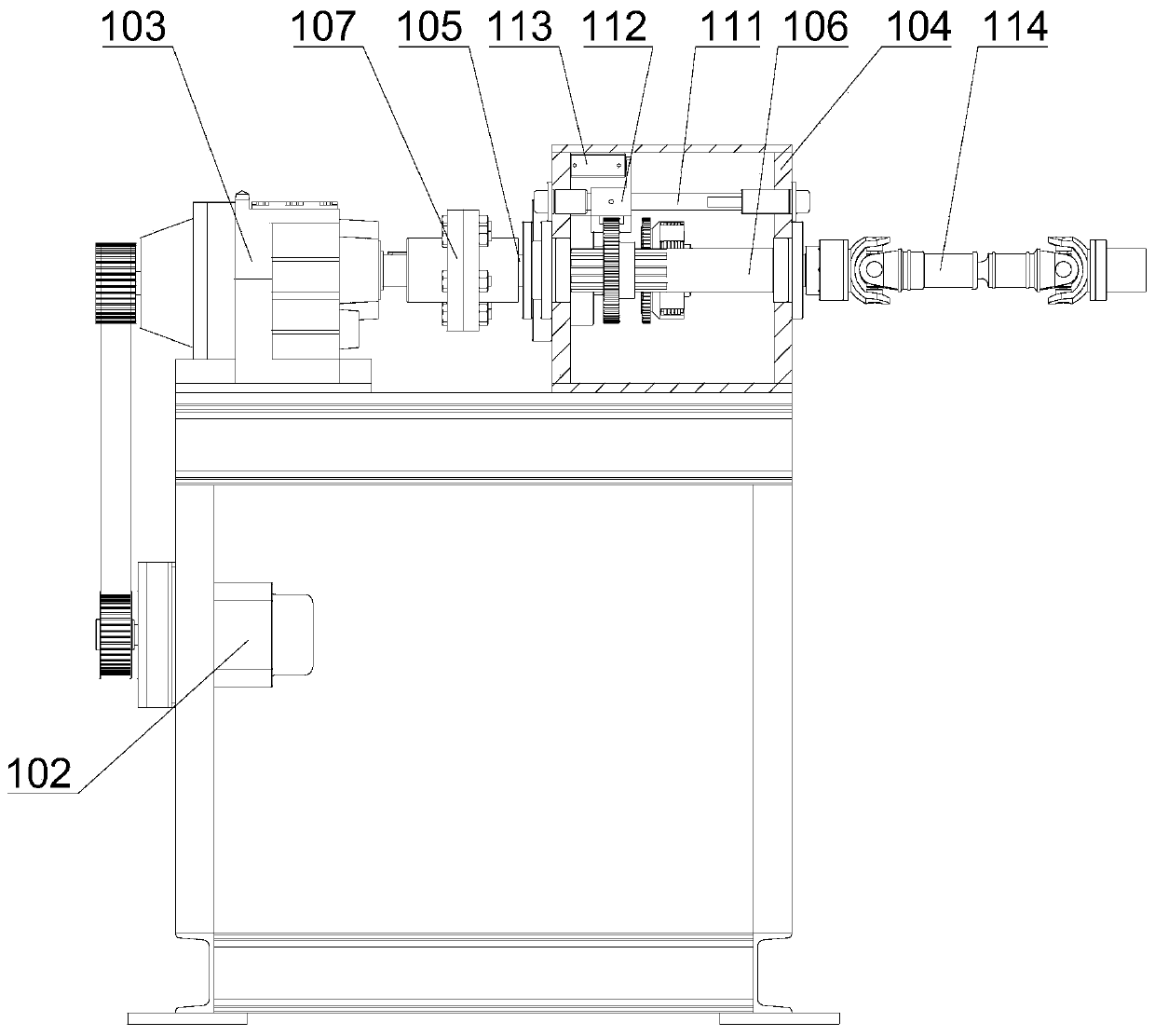

[0028] The winding driving mechanism 100 is arranged on one end of the unwinding machine winding roller 300, and it includes a frame 101 and a first drive motor 102, a gear reducer 103 and a gear box 104 arranged on the frame 101, and the gear box 104 is arranged There are transmission input shafts 105 and transmission output shafts 106 arranged in parallel.

[0029] The first drive motor 102 is in transmission connection with the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com