Perovskite solar cell taking tetraphenyl biphenyl diamine derivative as hole transport material

A technology of tetraphenylbiphenyldiamine and hole transport materials, which can be used in circuits, photovoltaic power generation, electrical components, etc., and can solve the problems of expensive hole transport layer materials, device voltage and current hysteresis, and unfavorable preparation of flexible devices. , to achieve the effect of saving material consumption, reducing the chance of hole recombination, and combining firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

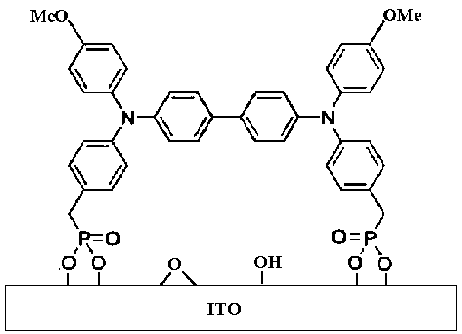

[0025] A perovskite solar cell using tetraphenyl benzidine derivatives as a hole transport material. The cell adopts a p-i-n structure and includes ITO glass, a hole transport layer, and a perovskite structure to absorb light from the sunlight incident side. layer, electron transport layer, back electrode. The preparation steps are as follows:

[0026] The first step, ITO glass cleaning:

[0027] Cut the material ITO glass into 10cm*10cm, with a square resistance of 10Ω, ultrasonically clean it with deionized water, acetone, and isopropanol for 5 minutes, blow dry with nitrogen, and then clean the ITO surface with ozone plasma for 10 minutes, and set it aside.

[0028] The second step, hole transport layer growth:

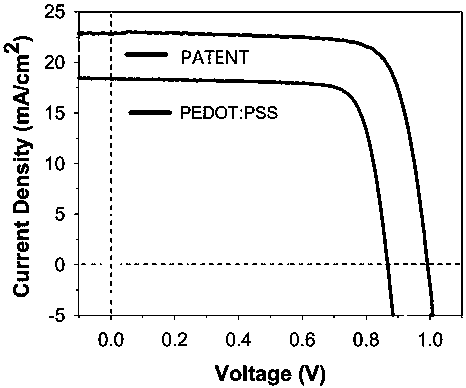

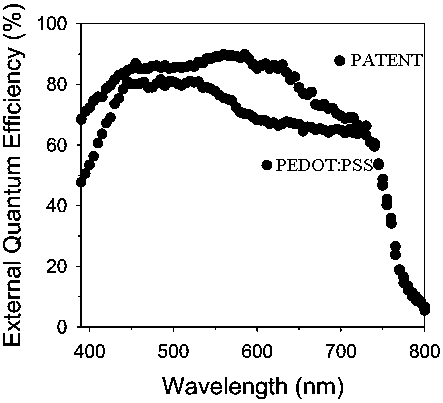

[0029] (1) Selection of material for the hole transport layer: the material of the hole transport layer is a derivative of tetraphenylbenzidine diamine, the four benzene rings of which have been functionalized with methoxy groups and phosphonate groups, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com