System capable of improving energy efficiency of low-temperature air energy heat pump and control method

A low-temperature air and control method technology, applied in high-efficiency regulation technology, refrigerators, refrigeration components, etc., can solve the problems of poor noise control, insufficient heating capacity of small compressors, weak heating capacity of air conditioners, etc. Thermal attenuation, improved user experience, strong heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

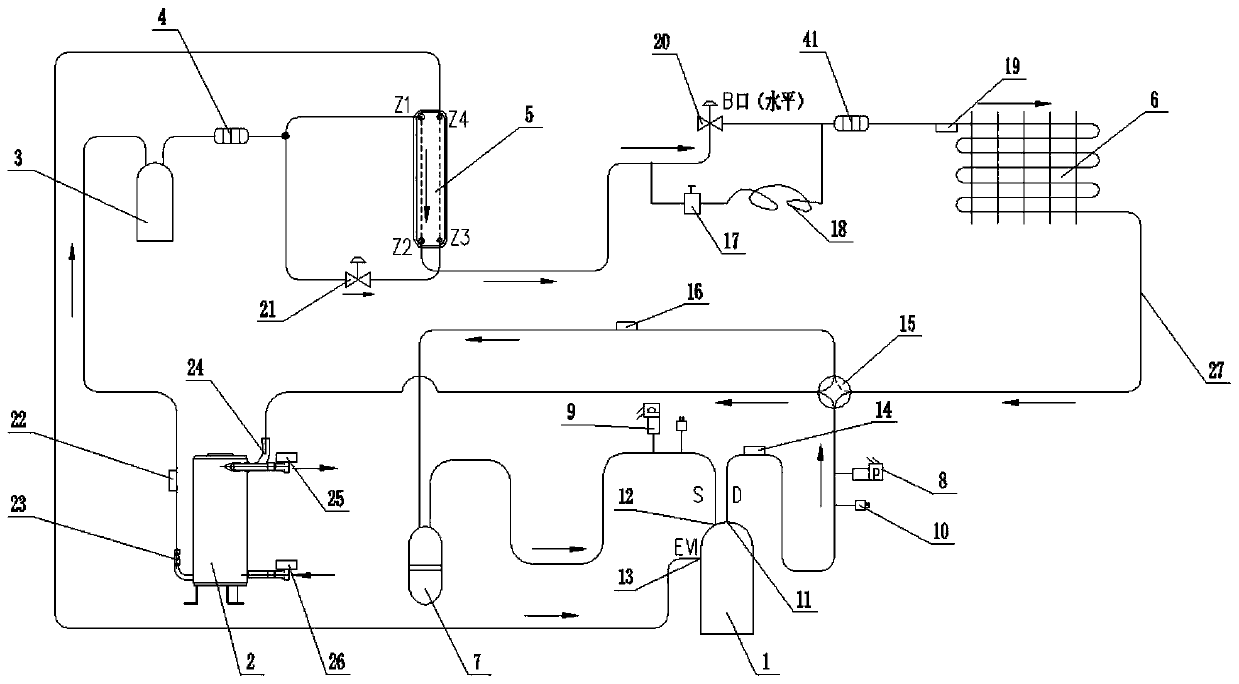

[0026] like figure 1 As shown, a system and control method for improving the energy efficiency of a low-temperature air source heat pump, including a compressor 1, an electromagnetic four-way reversing valve 15, a water side heat exchanger 2, a liquid reservoir 3, a first filter 4, an economical 5, the second filter 41, the wind-side heat exchanger 6, the electromagnetic four-way reversing valve 15, and the gas-liquid separator 7 are sequentially connected to form a circulating refrigerant flow path. The water outlet of the first filter 4 passes through three The through pipe is divided into two pipelines 27, one pipeline 27 is directly connected to the Z1 interface of the economizer 5, and the Z2 interface is connected to it, and the other pipeline 27 is provided with a culvert increasing electronic expansion valve 21, and is connected to the economizer 5 The Z3 interface is connected in, and the Z4 interface is connected to the compressor 1 through the second suction port 13...

Embodiment 2

[0032] On the basis of Embodiment 1, a fin probe 19 is installed between the water outlet of the second filter 41 and the wind-side heat exchanger 6 to protect the compressor 1 .

Embodiment 3

[0034] On the basis of Embodiment 2, the compressor 1 is provided with a first suction port 12, a second suction port 13 and an exhaust port 11, and the exhaust port 11 communicates with an electromagnetic four-way reversing valve 15 On the pipeline 27, an exhaust probe 14, a test valve 10 and a high pressure controller 8 are installed in sequence, and a test valve is installed in sequence on the pipeline 27 where the first suction port 12 communicates with the gas-liquid separator 7 10 and the low-pressure pressure controller 9 play the role of protecting the compressor 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com