Preparation method of high-crystallinity vanadium film

A high crystallinity, thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of irregular particle shape on the surface of vanadium thin film, and achieve remarkable grain growth orientation, simple steps, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

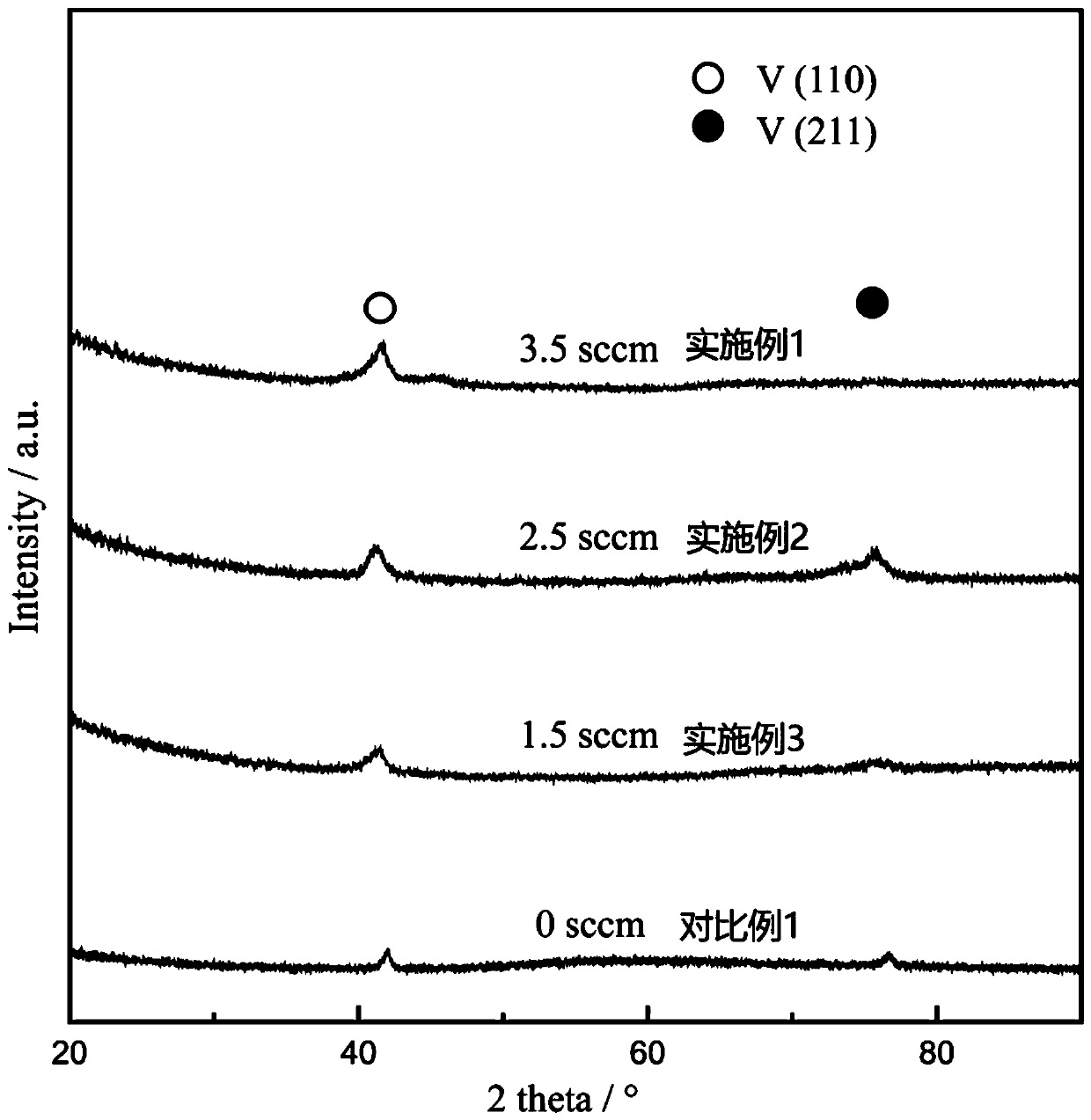

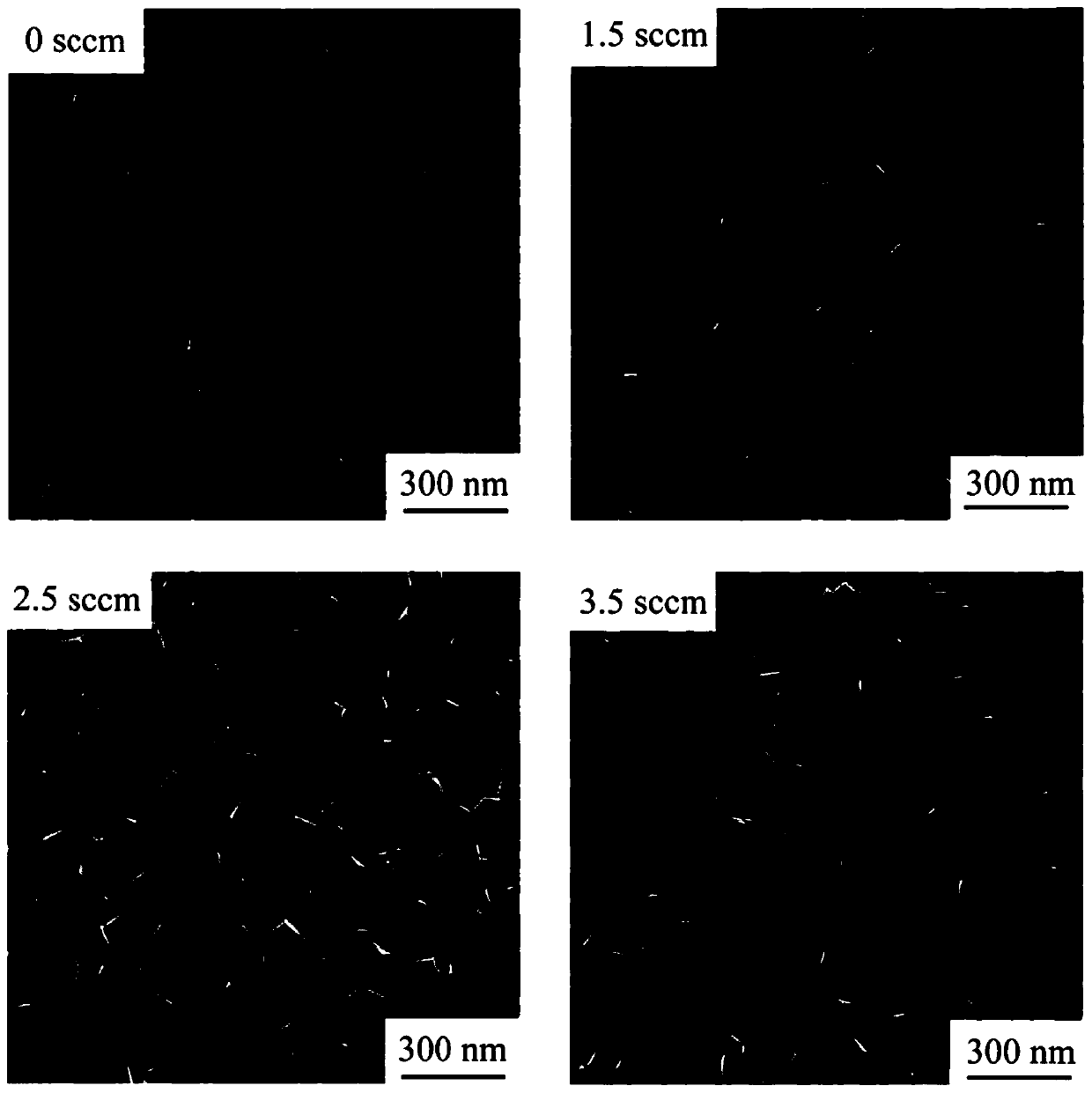

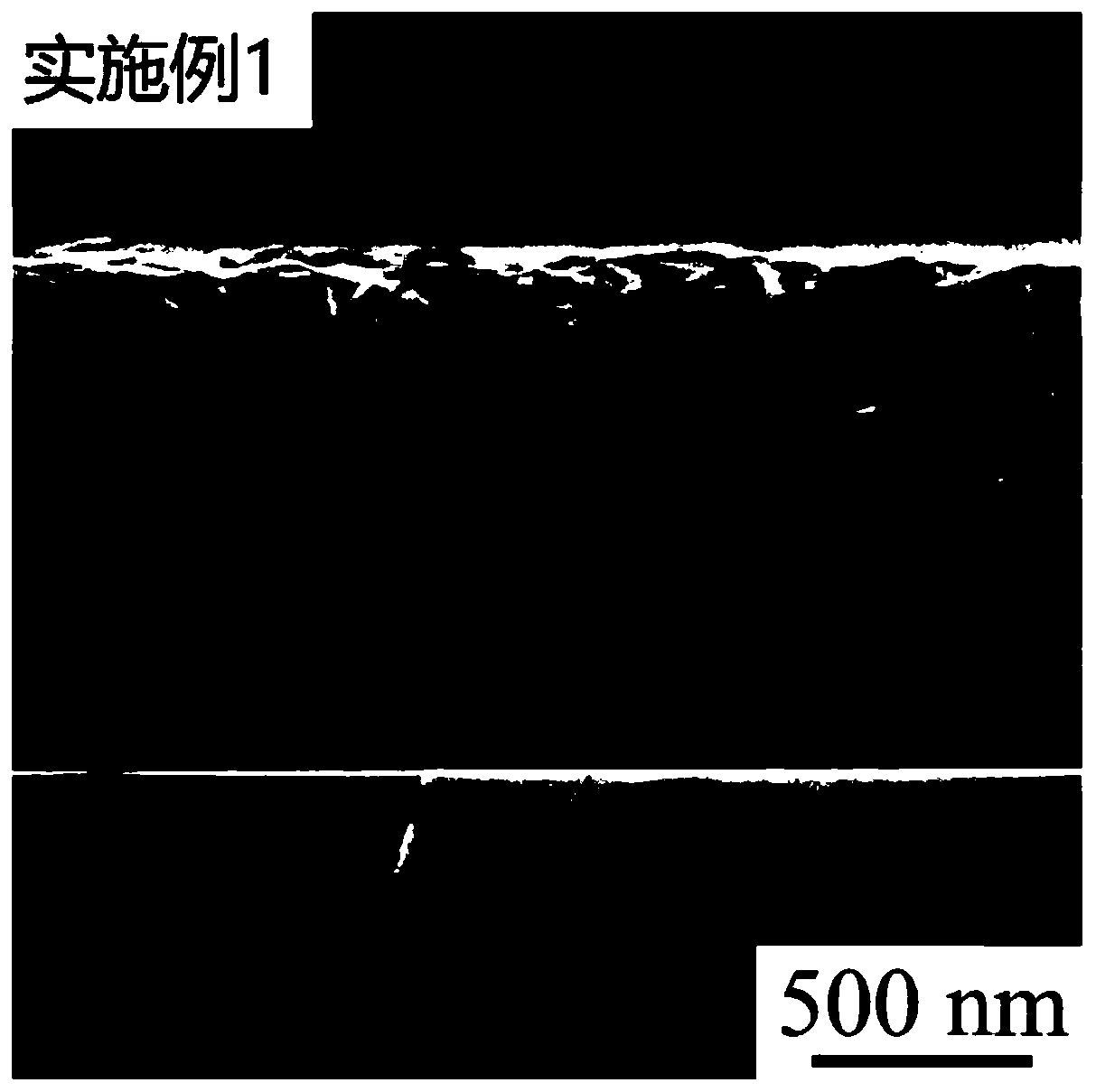

Embodiment 1

[0024] A kind of highly crystalline vanadium film, its preparation method comprises the following steps:

[0025] 1) Two V targets of the same specification (dia50×4mm, purity 99.95%) are symmetrically installed on a pair of sputtering targets in the deposition chamber of the target unbalanced magnetron sputtering equipment, and the distance between the target surfaces is adjusted to 13mm;

[0026] 2) Select a single crystal Si(111) substrate as the substrate, put the substrate in acetone and alcohol for ultrasonic cleaning, then rinse with deionized water, and blow dry with nitrogen;

[0027] 3) Place the substrate treated in step 2) on the substrate stage in the vacuum chamber of the magnetron sputtering equipment, located in the middle of the two vanadium targets, and evacuate to the background vacuum (5×10 -4 Pa);

[0028] 4) Feed argon and hydrogen into the deposition chamber of the magnetron sputtering equipment (the purity of both argon and hydrogen is 99.999%), adjus...

Embodiment 2

[0034] A kind of highly crystalline vanadium film, its preparation method comprises the following steps:

[0035] 1) Two V targets of the same specification (dia50×4mm, purity 99.95%) are symmetrically installed on a pair of sputtering target seats in the deposition chamber of the target unbalanced magnetron sputtering equipment, and the distance between the target surfaces is adjusted. 11mm;

[0036] 2) Select a single crystal Si(111) substrate as the substrate, put the substrate in acetone and alcohol for ultrasonic cleaning, then rinse with deionized water, and blow dry with nitrogen;

[0037] 3) Place the substrate treated in step 2) on the substrate stage in the cavity of the magnetron sputtering equipment, located in the middle of the two vanadium targets, and evacuate to the background vacuum (5×10 -4 Pa);

[0038] 4) Pass argon and hydrogen into the deposition chamber of the magnetron sputtering equipment, adjust the gas flow meter to stabilize the gas flow, and adju...

Embodiment 3

[0044] A kind of highly crystalline vanadium film, its preparation method comprises the following steps:

[0045] 1) Two V targets of the same specification (dia50×4mm, purity 99.95%) are symmetrically installed on a pair of sputtering target seats in the deposition chamber of the target unbalanced magnetron sputtering equipment, and the distance between the target surfaces is adjusted. 9mm;

[0046] 2) Select a single crystal Si(111) substrate as the substrate, put the substrate in acetone and alcohol for ultrasonic cleaning, then rinse with deionized water, and blow dry with nitrogen;

[0047] 3) Place the substrate treated in step 2) on the substrate stage in the cavity of the magnetron sputtering equipment, located in the middle of the two vanadium targets, and evacuate to the background vacuum (5×10 -4 Pa);

[0048] 4) Pass argon and hydrogen into the deposition chamber of the magnetron sputtering equipment, adjust the gas flow meter to stabilize the gas flow, and adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com