Continuous hot-dip galvanized aluminum-magnesium production method, air knife device, and air knife system

A zinc-aluminum-magnesium and air-knife technology, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problem of threatening the service life of work rolls of tension levelers and skin pass roll coaters, increasing the Eliminate the wear and tear of the squeezing roller and the pressure roller, and the poor surface quality of the product, and achieve the effects of easy promotion, improved uniformity, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

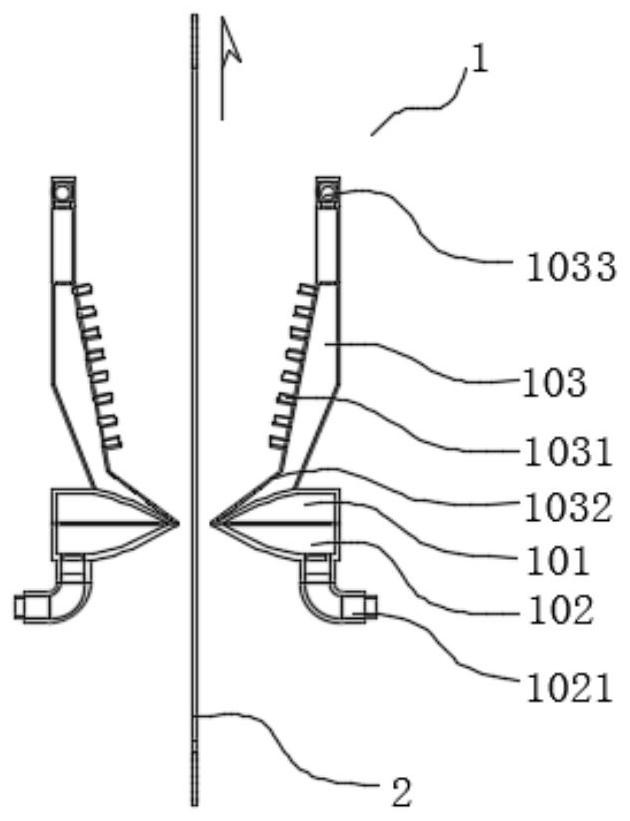

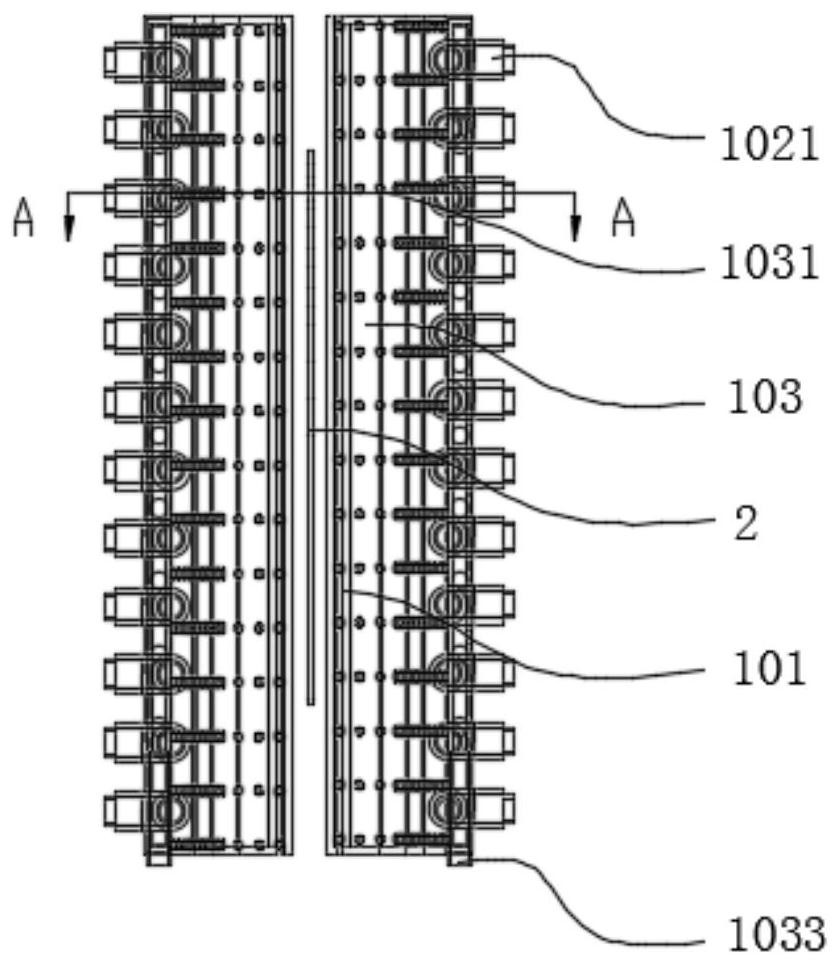

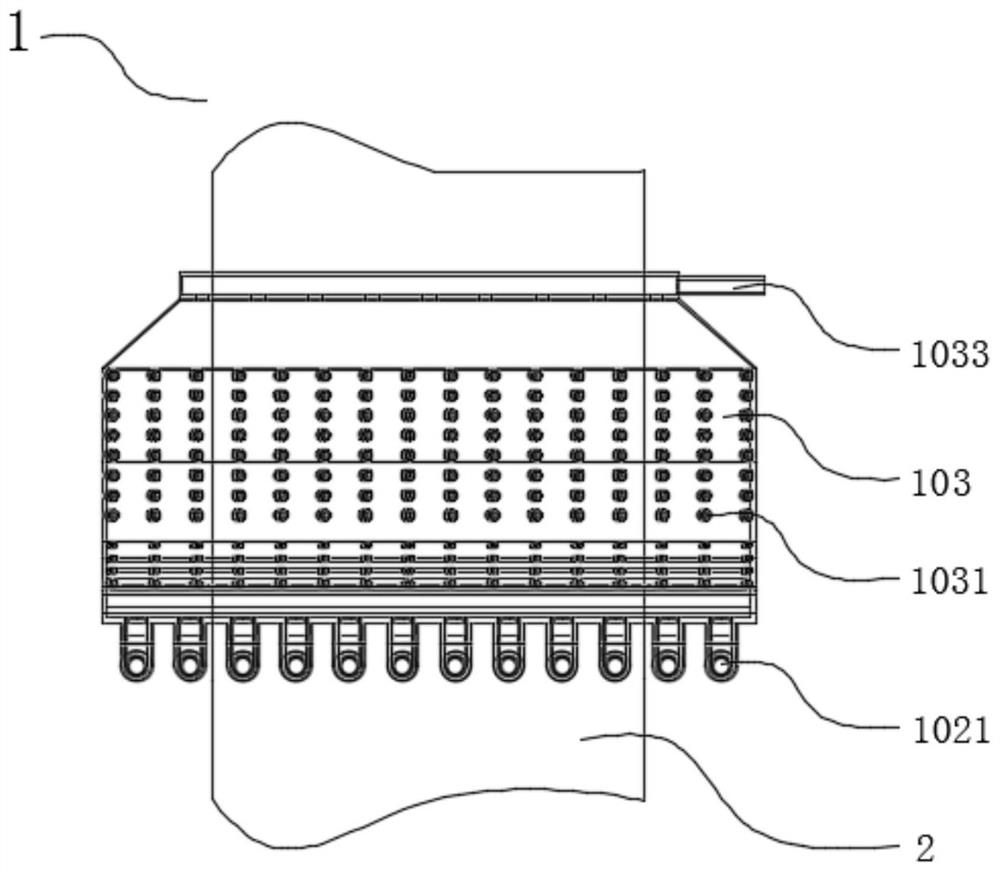

[0056] This embodiment provides an air knife device for continuous hot-dip galvanizing of aluminum and magnesium, referring to figure 1 and Figure 4 As shown, the cooling air knife 1 is an air knife device, which includes a main air knife and an inclined cooling device 103 , and the main air knife includes an upper knife lip 101 and a lower knife lip 102 . After the upper lip 101 and the lower lip 102 are fastened up and down, the cavity communicates.

[0057] The length of the main air knife of the cooling air knife 1 is less than or equal to the width of the inclined cooling device 103, and the designed width of the inclined cooling device 103 is 1.5-1.7 times of the maximum width of the strip produced.

[0058] The bottom of the lower knife lip 102 is connected with the main air knife intake pipeline 1021. In the present embodiment, the main air knife intake pipeline 1021 is a multi-hole air supply mode connected by multiple groups of air pipes. The gas supply is normal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com