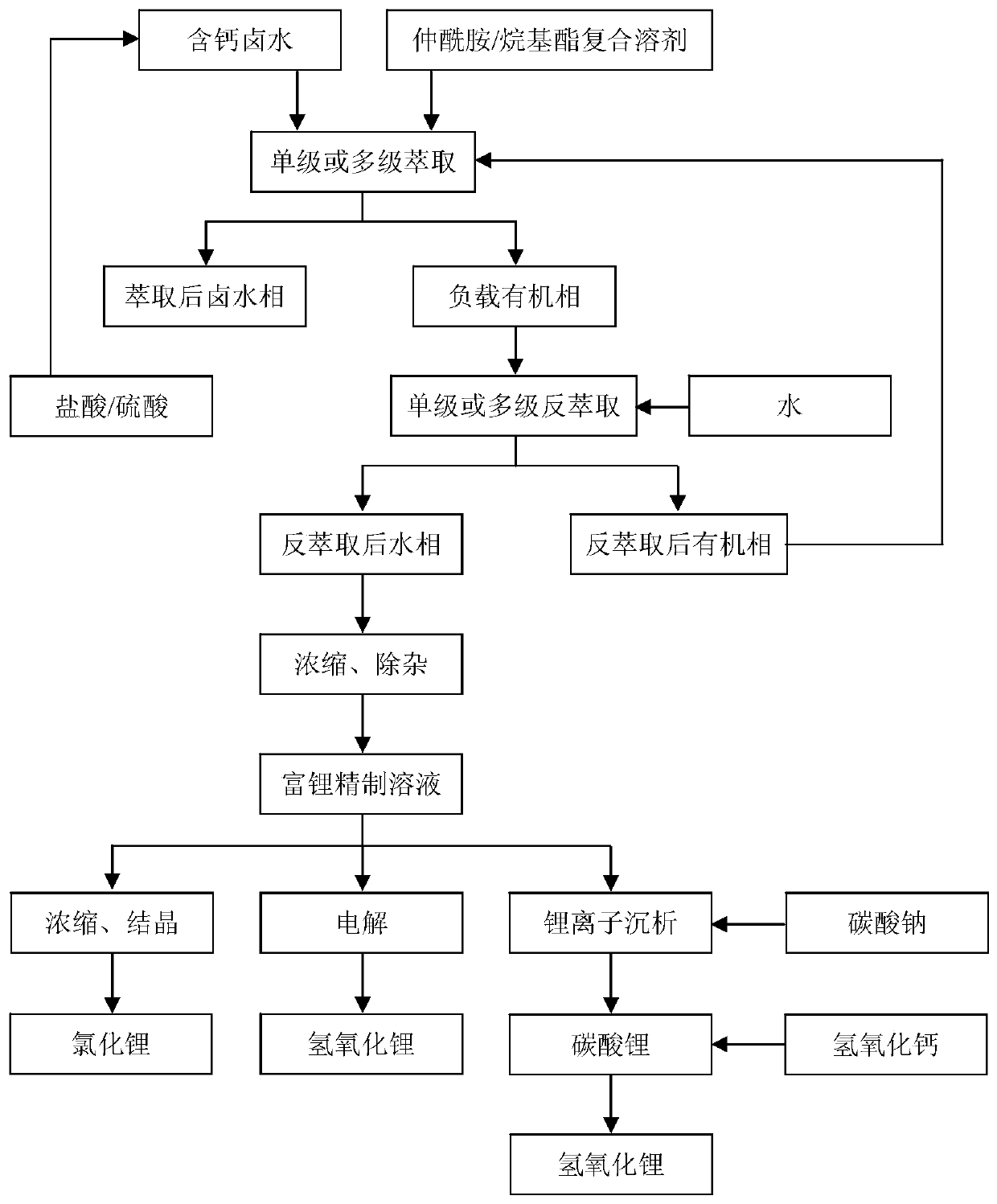

Extraction system and method of using secondary amide/alkyl ester composite solvent to separate calcium and extract lithium from brine containing calcium and application thereof

A composite solvent and secondary amide technology, which is applied in the extraction system field of composite solvent to separate calcium from calcium-containing brine to extract lithium, can solve the limitation of the decrease in the mass ratio of calcium to lithium, the failure to realize the development of lithium resources, and the difficulty of separation and separation, etc. problem, to achieve the effect of increasing entropy and entropy, simple structure and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Li in a calcium-containing brine + and Ca 2+ The contents are 3.79g / L and 221.99g / L respectively, and the mass ratio of calcium to lithium is 58.62:1, of which Na + , K + , Mg 2+ , Cl - and B 2 o 3 The contents are 0.83, 5.32, 2.03, 424.10 and 2.42g / L respectively, and the brine density is 1.44g / cm 3 , the pH value of the brine is 5.5, and the ion concentration in the brine is prepared according to the brine composition of an oilfield in Nanyi Mountain, Qaidam Basin, Qinghai. The oilfield brine is degreased by an oil-water separator in advance. Get 6mL of this kind of bittern in the 100mL ground mouth Erlenmeyer flask, then add 21mL N-isooctyl isovaleramide extractant and 9mL ethyl laurate co-extractant therein, the co-extractant accounts for 30% of the organic phase volume, The volume ratio of organic phase to brine is 5:1. Put magnets in the Erlenmeyer flask, insert the matching air condenser into the mouth of the flask to prevent the liquid from splashing out...

Embodiment 2

[0057] Li in a calcium-containing brine + and Ca 2+ The contents are 4.04g / L and 224.03g / L respectively, and the mass ratio of calcium to lithium is 55.46:1, of which Na + , K + and Cl - The contents are 0.88, 5.68 and 423.91g / L respectively, and the brine density is 1.45g / cm 3 , the brine pH value is adjusted to 1.9, and the oil field brine is degreased with an oil-water separator in advance. Get 6mL of this kind of bittern in the 100mL ground mouth Erlenmeyer flask, then add 21mL N-isooctyl isovaleramide extractant and 9mL ethyl laurate co-extractant therein, the co-extractant accounts for 30% of the organic phase volume, The volume ratio of organic phase to brine is 5:1. Put magnets in the Erlenmeyer flask, insert the matching air condenser into the mouth of the flask to prevent the liquid from splashing out, place it in a DF-101S collector type constant temperature heating magnetic stirrer, mix and stir at 20°C, and extract for 20 minutes. Then the mixed liquid was t...

Embodiment 3

[0063] Li in a calcium-containing brine + and Ca 2+ The contents are 3.62g / L and 222.28g / L respectively, and the mass ratio of calcium to lithium is 61.33:1, of which Na + , K + and Cl - The contents are 0.79, 5.09 and 419.79g / L respectively, and the brine density is 1.44g / cm 3 , the pH value of the brine is 1.2, and the oil field brine is degreased with an oil-water separator in advance. Take 6mL of this kind of brine in a 100mL ground-mouth Erlenmeyer flask, then add 21mL N-isooctyl isovaleramide extractant and 9mL ethyl myristate co-extractant, the co-extractant accounts for 30% of the volume of the organic phase , the volume ratio of organic phase to brine is 5:1. Put magnets in the Erlenmeyer flask, insert the matching air condenser into the mouth of the flask to prevent the liquid from splashing out, place it in a DF-101S collector type constant temperature heating magnetic stirrer, mix and stir at 10°C, and extract for 20 minutes. Then the mixed liquid was transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com