A kind of polycarbonate composition and preparation method thereof

A technology of polycarbonate and composition, which is applied in the field of engineering plastics, can solve the problems of reducing the anti-fouling ability of materials, failing to achieve a rigid-tough balance, and large damage to material toughness, so as to reduce surface energy, reduce interface strength, and improve material toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

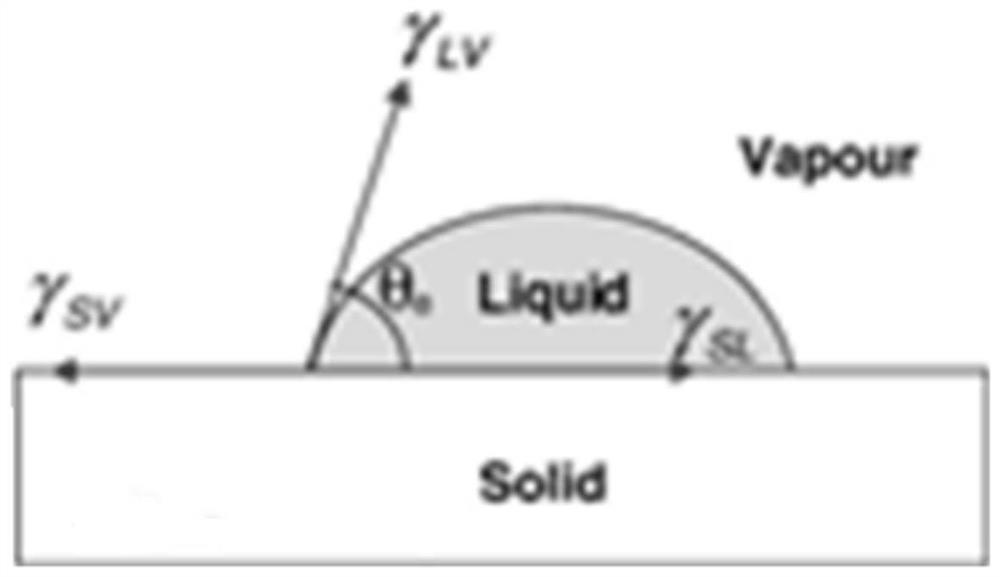

Method used

Image

Examples

Embodiment 1-6

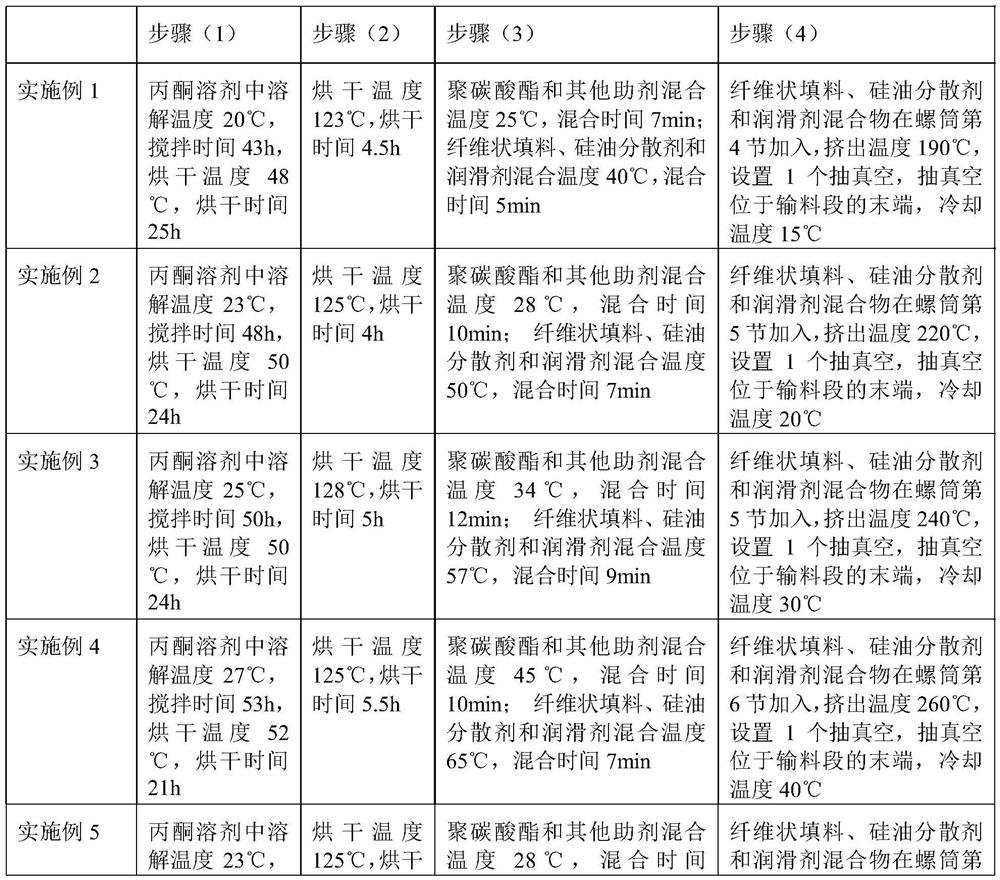

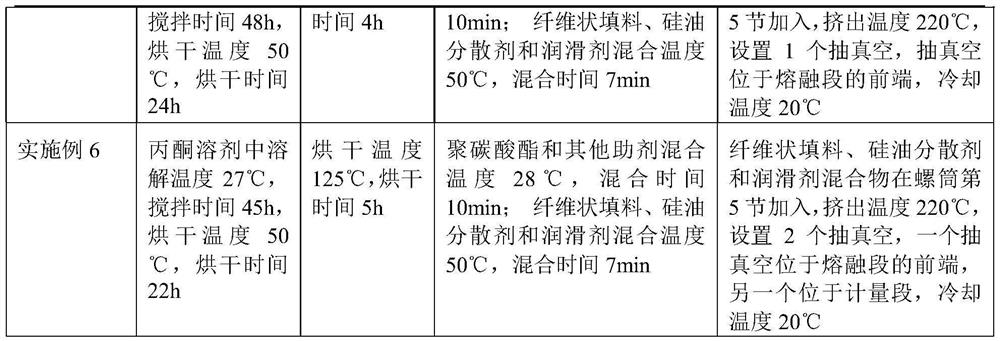

[0045] See Table 2 for the selection of process parameters in the preparation of the polycarbonate composition of Examples 1-6.

[0046] The selection of process parameter in the preparation of table 2 embodiment 1-6 polycarbonate composition

[0047]

[0048]

[0049] The selection of process parameters in the preparation of the polycarbonate composition in Comparative Examples 1-9 can refer to Examples 1-6.

[0050] Four, polycarbonate composition in embodiment 1-6 and comparative example 1-9

[0051] Prepare the polycarbonate composition in embodiment 1-6 and comparative example 1-9 according to the above-mentioned method, the specific proportioning of polycarbonate composition and its performance detection in embodiment 1-6 are shown in Table 3, comparative example 1- See Table 4 for the specific proportioning and performance testing of the polycarbonate composition in 9.

[0052] Concrete proportioning (parts by weight) and test performance results thereof of tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com