A nano energetic material based on thermal solvent molecule induced controllable growth and its preparation method

A thermal solvent and nanotechnology, which is applied in the field of nanometer energetic materials and their preparation, can solve the problems of difficulty in finely regulating grain size and morphology, complicated technical processes, etc., and achieves easy amplification, simple process, and small solvent consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

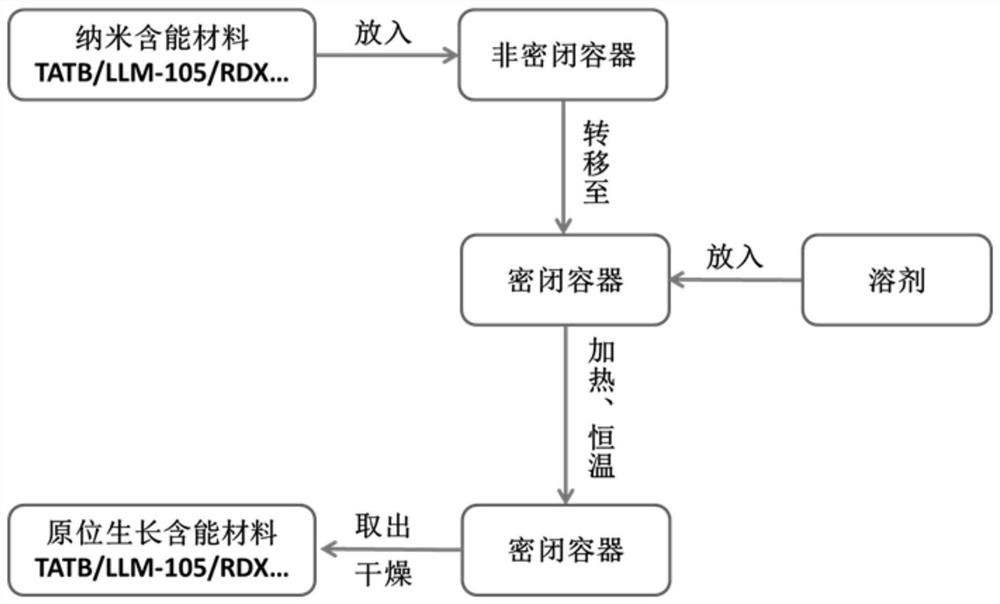

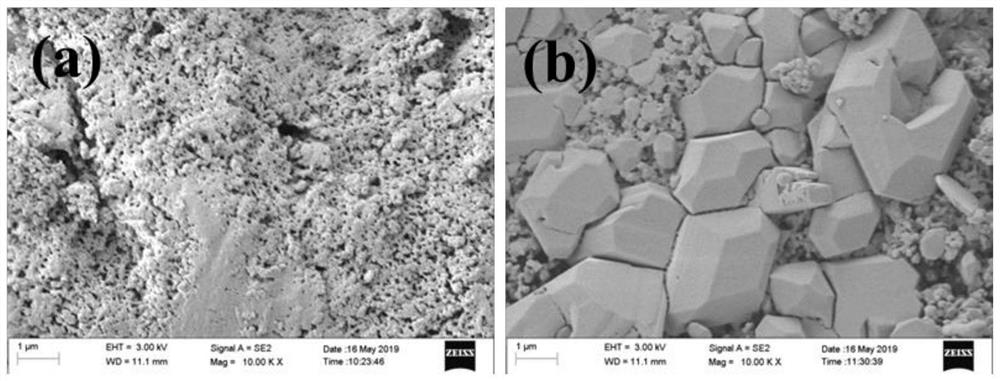

[0021] The preparation process of the present invention is as figure 1 As shown, take by weighing nanometer TATB explosive 1g, it is put into the polytetrafluoroethylene container that volume is 20ml. Measure 5ml of ethanol with a graduated cylinder, and pour it into a Teflon container with a capacity of 100ml. Gently place the polytetrafluoroethylene containing nano-TATB in the polytetrafluoroethylene container containing ethanol with tweezers, and cover the lid so that the nano-TATB explosive is sealed in the polytetrafluoroethylene container containing ethanol. Subsequently, the device was put into an oven, and the temperature was raised to 60 °C at a rate of 10 °C / min. The ethanol in the container volatilized and reached a stable saturated vapor pressure. After keeping the temperature for five days, the temperature was lowered to room temperature at a cooling rate of 10°C / min. The device is taken out, the bottle cap is opened, and the polytetrafluoroethylene container co...

Embodiment 2

[0023] Weigh 1g of nanometer TATB explosive and put it into a polytetrafluoroethylene container with a volume of 20ml. Measure 10ml of dimethyl sulfoxide (DMSO) with a graduated cylinder, and pour it into a polytetrafluoroethylene container with a capacity of 100ml. Use tweezers to gently place the polytetrafluoroethylene containing nano-TATB in a polytetrafluoroethylene container containing dimethyl sulfoxide (DMSO) solvent, and cover the lid to seal the nano-TATB explosive in the container containing dimethyl sulfoxide (DMSO). in a polytetrafluoroethylene container of sulfone (DMSO) solvent. Subsequently, the device was put into an oven, and the temperature was raised to 80°C at a rate of 5°C / min. The dimethyl sulfoxide (DMSO) solvent in the container volatilized and reached a stable saturated vapor pressure. Under the induction of DMSO solvent thermal molecules, The nano-TATB particles gradually grew up in situ. After two days of constant temperature, the temperature was l...

Embodiment 3

[0025] Weigh 1 g of nanometer LLM-105 explosive and put it into a polytetrafluoroethylene container with a volume of 20 ml. Measure 5ml of ethanol with a graduated cylinder, and pour it into a Teflon container with a volume of 100ml. Gently place the polytetrafluoroethylene containing nano-LLM-105 in the polytetrafluoroethylene container containing ethanol with tweezers, and cover the lid so that the nano-LLM-105 explosive is sealed in the polytetrafluoroethylene container containing ethanol . Subsequently, the device was put into an oven, and the temperature was raised to 65°C at a rate of 10°C / min. The ethanol in the container volatilized and reached a stable saturated vapor pressure. After growing up, keep the temperature for five days, and then lower the temperature to room temperature at a cooling rate of 10°C / min. Take out the device, open the bottle cap, put the polytetrafluoroethylene container containing the nanometer LLM-105 in an oven to dry for 2 hours, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com