Adhesive tape blanking device for copper foil adhesive tape production

A tape and copper foil technology, applied in metal processing and other directions, can solve the problems of low safety performance, easy accidental injury to staff, inconvenient to replace the punching head, etc., to achieve good sealing effect, save punching time, and speed up punching. The effect of the adjudication process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

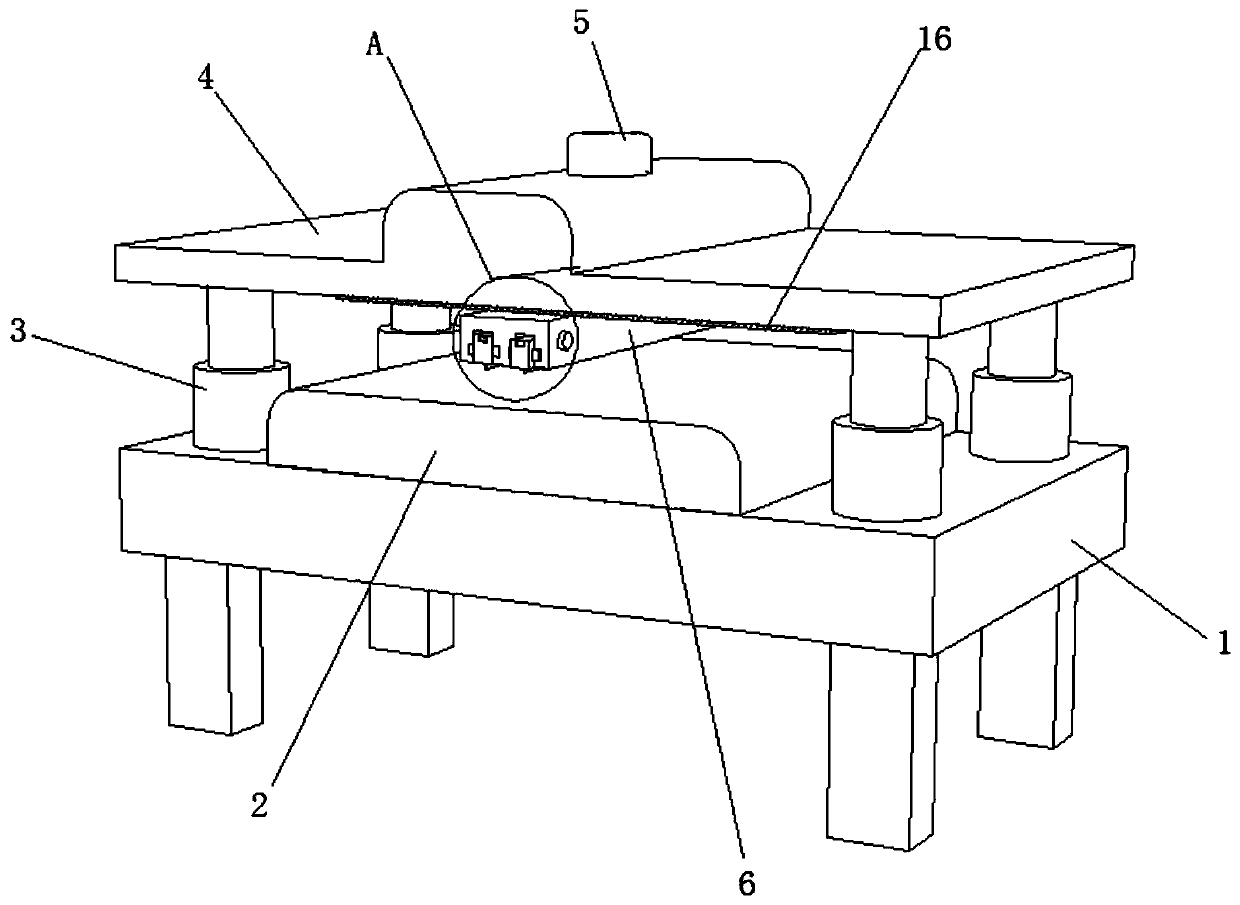

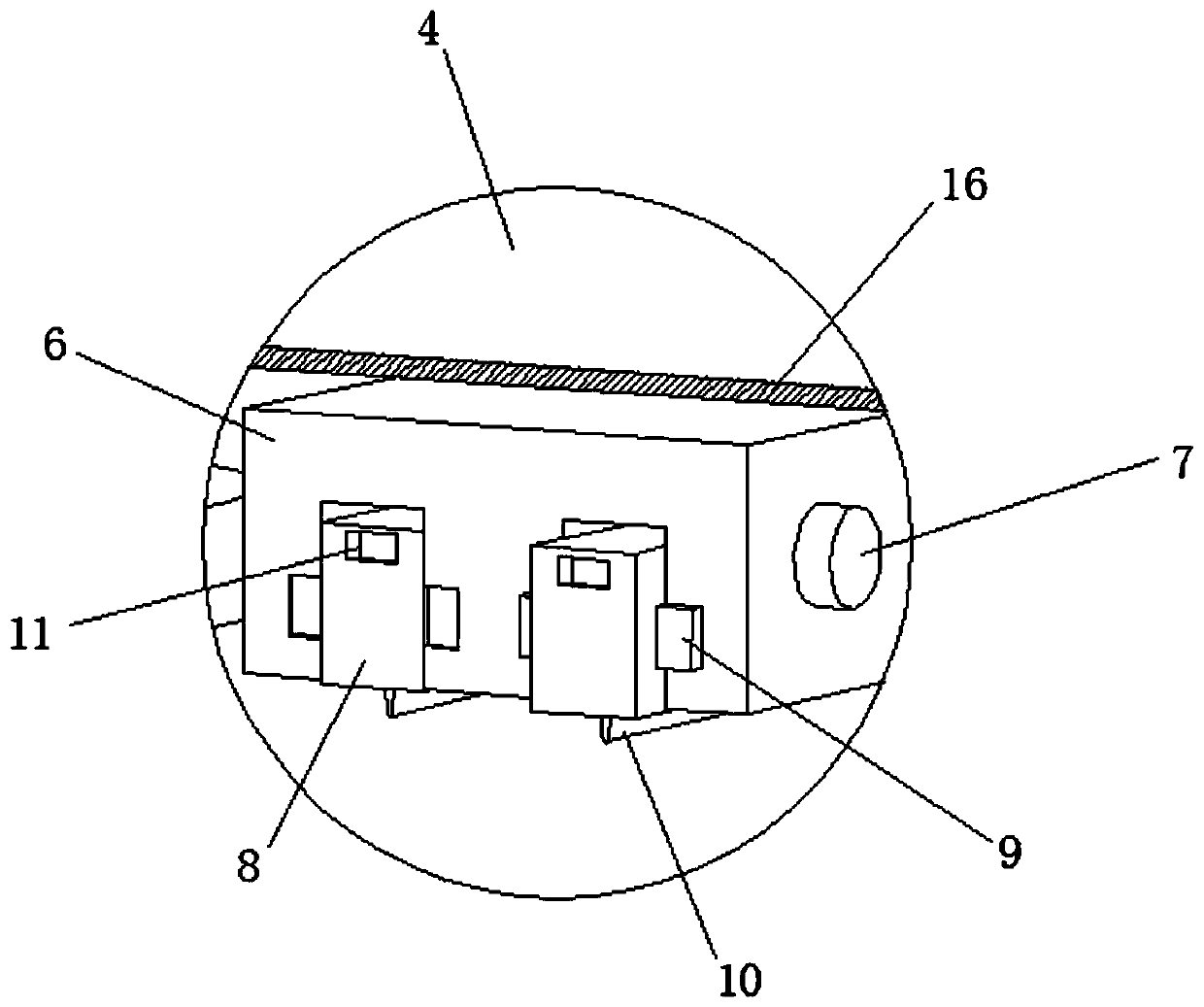

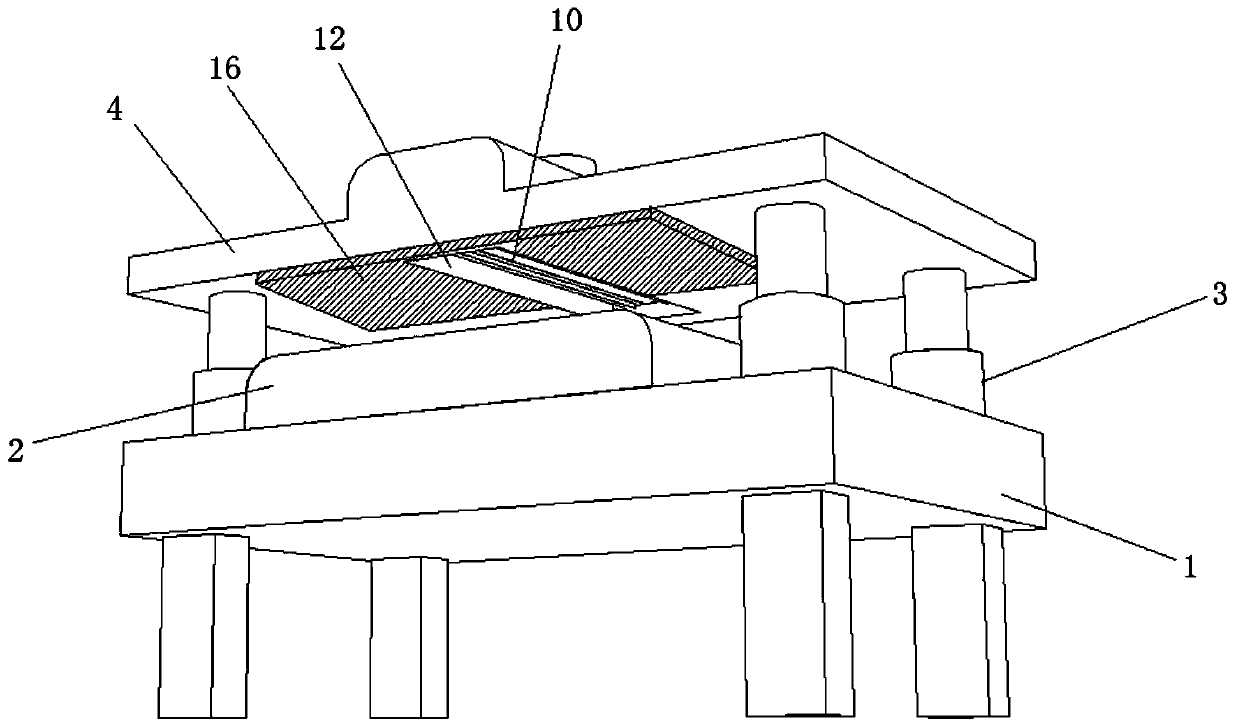

[0032] see figure 1 and image 3 , a tape punching device for copper foil tape production, including a punching table 2 fixedly connected to the upper end of the workbench 1, the upper side of the punching table 2 is provided with a lift cover 4, and the lift cover 4 and the workbench 1 There are many pairs of electric telescopic rods 3 fixedly connected, and a through hole is drilled from top to bottom at the center of the lifting cover plate 4, please refer to figure 1 and figure 2 , a cylinder 5 is connected to the center of the upper end face of the lifting cover plate 4, and the power output end of the cylinder 5 passes through the through hole and is fixedly connected to the lifting block 6, please refer to image 3 , the lower end of the lifting cover plate 4 is excavated with a receiving groove 12 matching the lifting block 6, please refer to Figure 4 , the lower end of the lifting block 6 is dug with a protective groove 14, and the inner side wall of the protecti...

Embodiment 2

[0039] see image 3 , the lower end surface of the lifting cover 4 is glued with a soft pad 16, and the soft pad 16 matches the upper end surface of the punching table 2. When idle, the lifting cover 4 is covered on the upper side of the punching table 2, and the soft pad 16 is directly connected to the punching table 2. The upper end surfaces of the table 2 are in contact with each other, which can play a certain buffering effect, and the sealing effect is better, so as to better protect the cutter head 10 from being corroded by the external environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com