Processing method applied to flexible graphite metal wound gasket

A technology of metal wound gasket and processing method, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of poor sealing performance, difficult installation, high labor intensity, etc., and achieve good sealing performance, high production efficiency, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

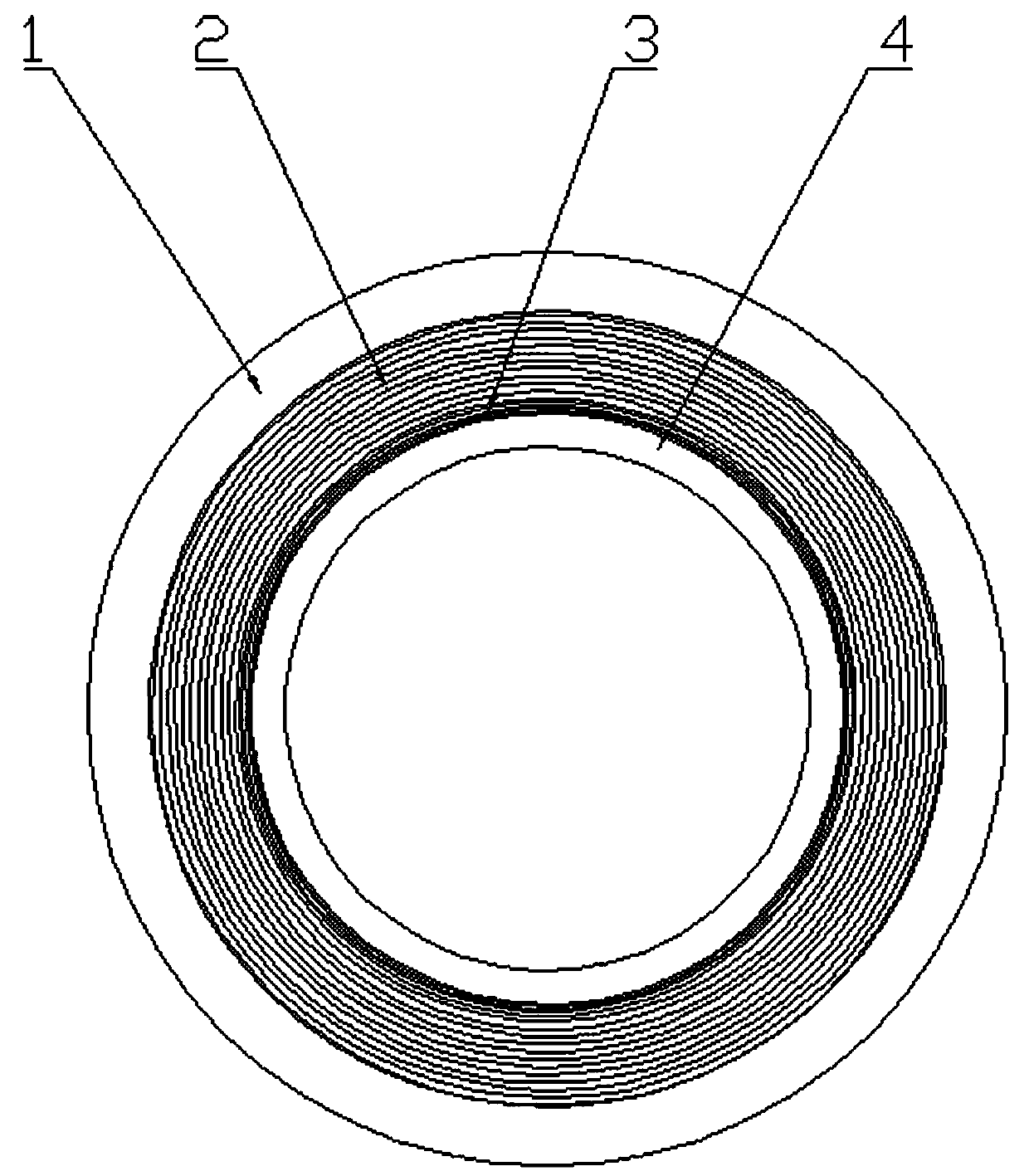

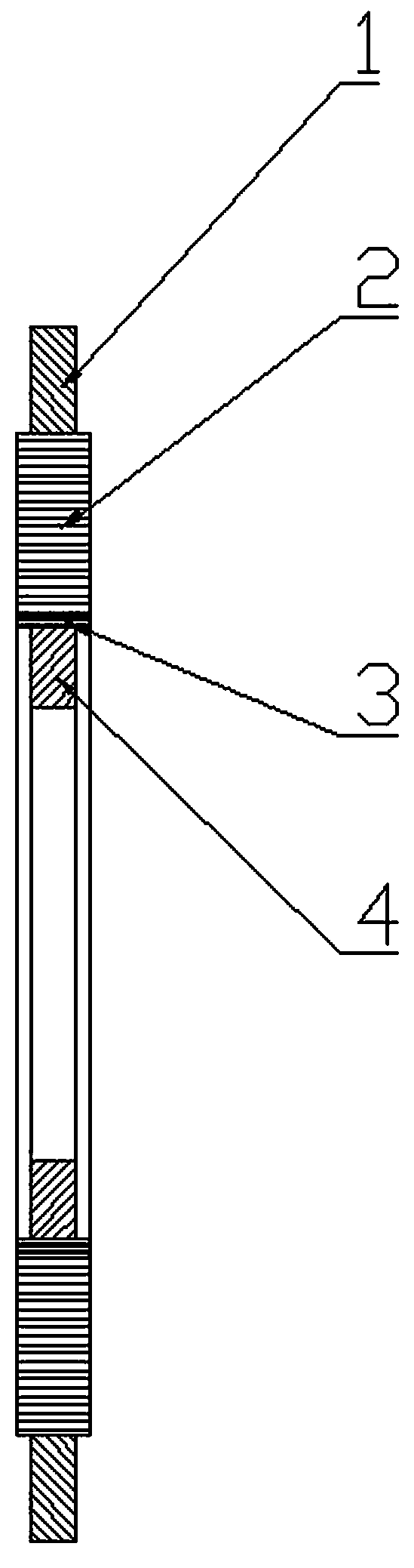

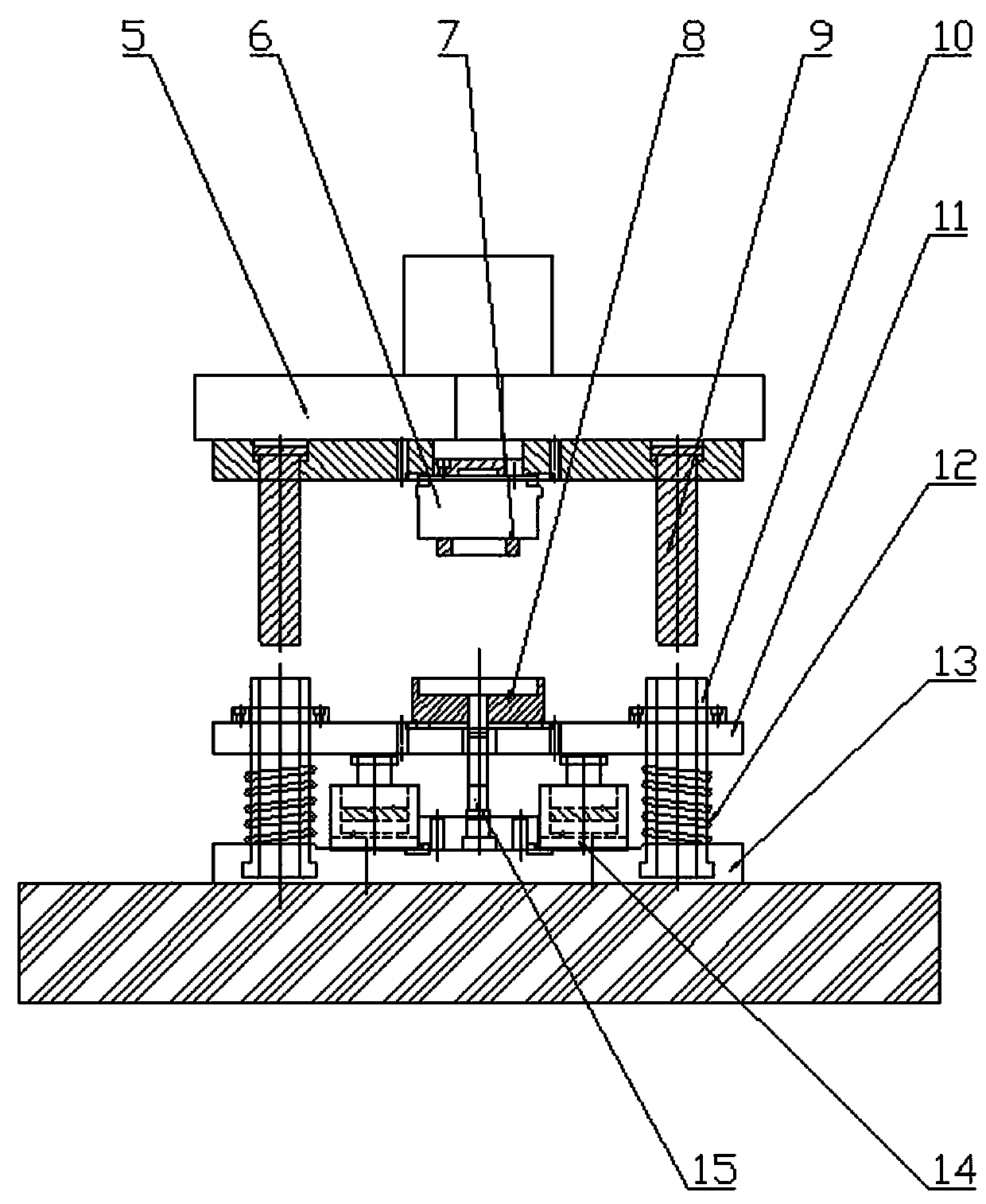

[0029] Example: such as Figure 1-8 As shown, a processing method applied to flexible graphite metal spiral wound gaskets follows the following steps:

[0030] Step 1: First, the steel plate is stamped and formed by the upper die 6 and the lower die 8 of the punching machine to form the blanks of the outer ring 1 and inner ring 4 at one time, leaving a margin for the inner and outer circles of the outer ring 1 and inner ring 4 . Next, the inner and outer circles of the outer ring 1 and the inner ring 4 are finished by machining. When stamping the outer ring 1 and the inner ring 4 to form, the upper mold 6 on the die frame 5 on the punching machine is guided by the phase-displacement nesting of the punching machine guide column 10 on the punching die base 13 through 4 punching machine positioning guide rods 9, so that The upper mold 6 and the lower mold 8 are coaxially molded, and the top ring 7 is installed in the upper mold 6, and the stamping die base 13 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com