Preparation method of magnetic aluminum salt lithium adsorbent

A lithium adsorption and aluminum salt technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem that powder adsorbents cannot be directly applied to large-scale continuous industrial production and liquid fluidity And problems such as poor permeability and immature molding technology, to achieve the effect of simple and reasonable preparation method, mild overall conditions and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

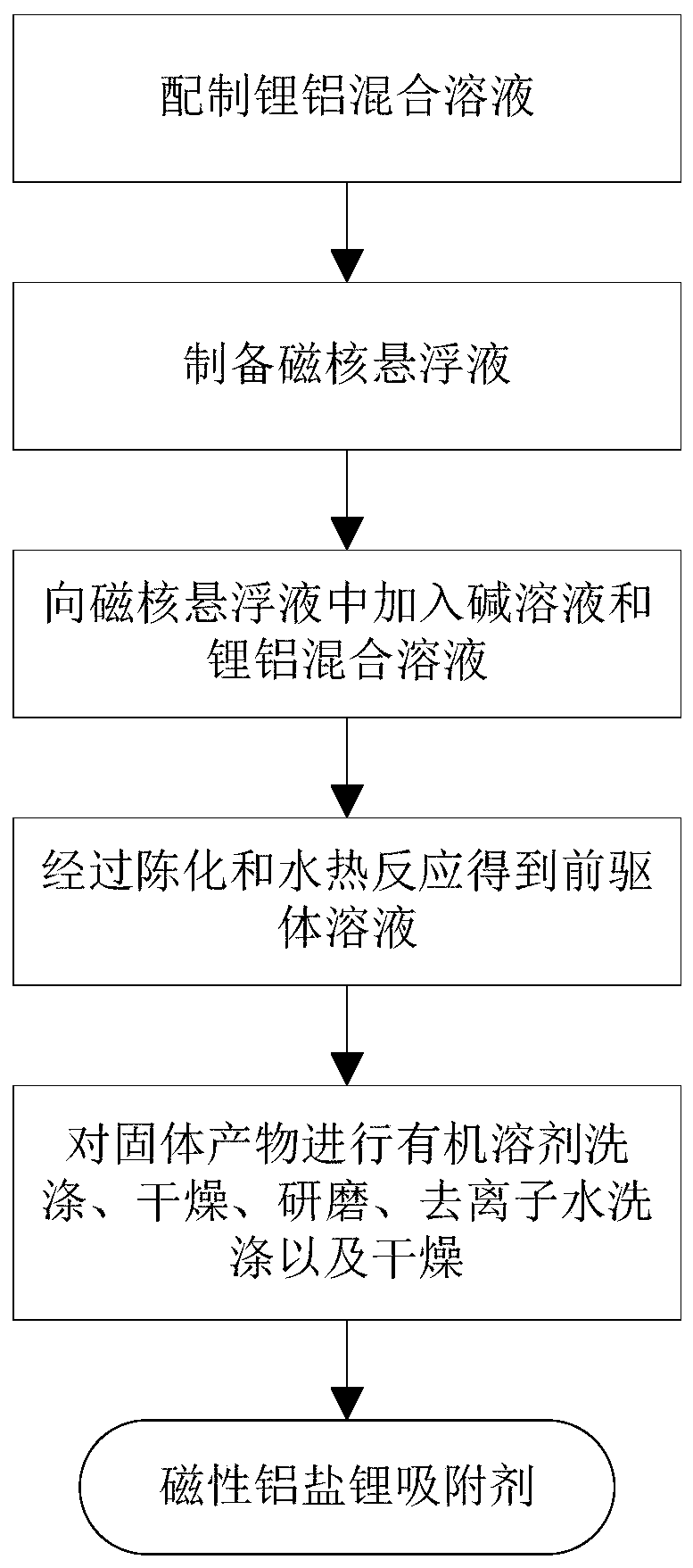

[0026] like figure 1 As shown, the invention discloses a preparation method of a magnetic aluminum salt lithium adsorbent, comprising the following steps:

[0027] Step 1, dissolving soluble lithium salt and aluminum salt in deionized water to prepare lithium-aluminum mixed solution;

[0028] Step 2, adding magnetic nanoparticles to deionized water to obtain a magnetic nucleus suspension;

[0029] Step 3, under stirring conditions, add alkali solution and lithium-aluminum mixed solution to the magnetic nucleus suspension, control the end point pH value to 3-12, preferably the end point pH value is 4.5;

[0030] Step 4, stop stirring, and then obtain the precursor solution after aging and hydrothermal reaction in sequence;

[0031] In step 5, the solid product is separated from the precursor solution, and the solid product is washed with an organic solvent, dried, ground, washed with deionized water, and dried in order to finally obtain a magnetic aluminum salt lithium adsorb...

Embodiment 1

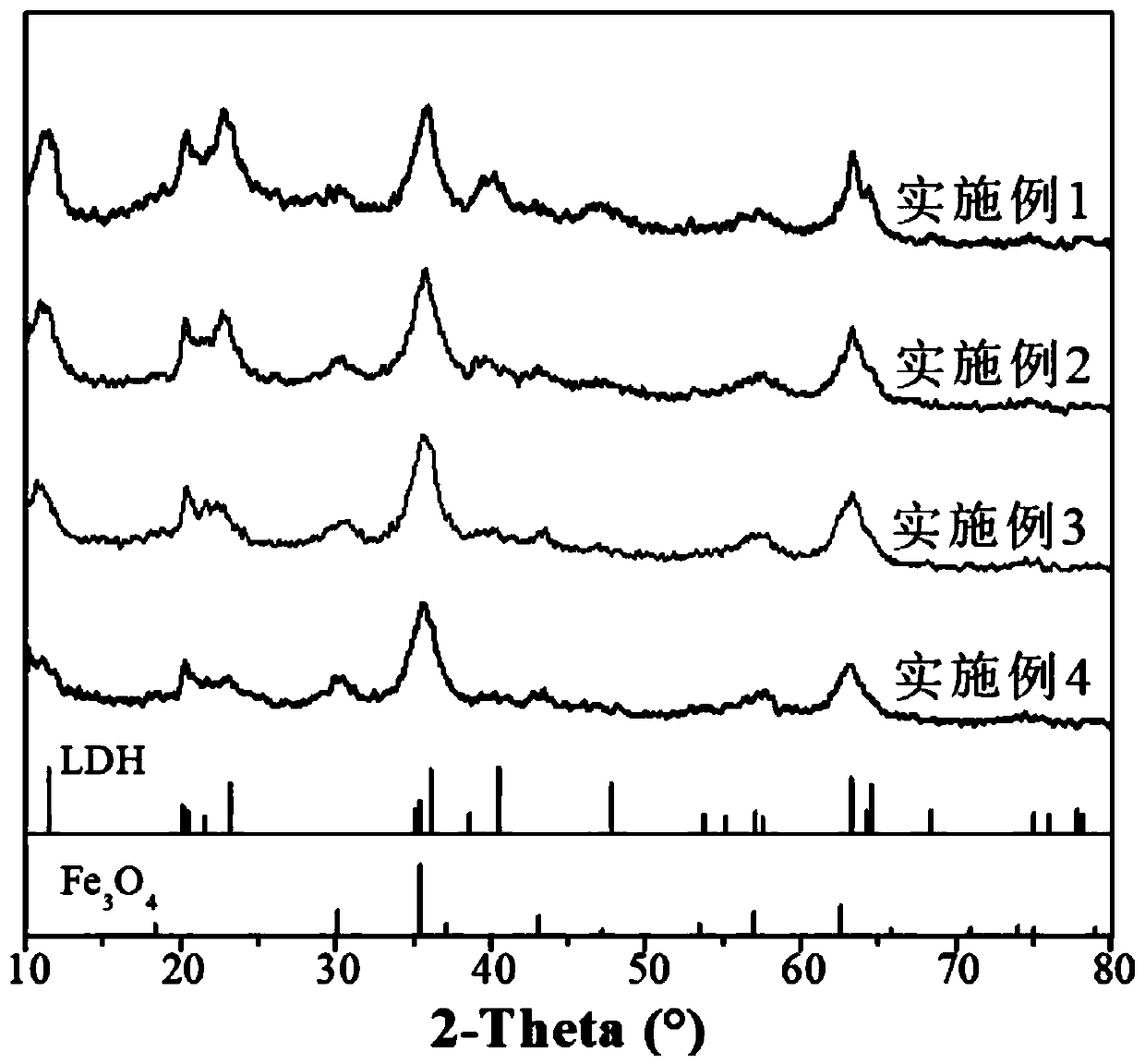

[0047] Weigh 19.57g AlCl respectively 3 ·6H 2 O and 1.86g LiCl·H 2 O was dissolved in 80mL of deionized water, ultrasonically treated at 60°C for 60 minutes and mixed evenly to prepare a lithium-aluminum mixed solution with Li / Al=0.8 / 2, in which the lithium ion concentration was 0.4mol / L and the aluminum ion concentration was 1.0mol / L. 1.20g Fe prepared by co-precipitation method 3 o 4 Add the solid powder into 100mL deionized water, and ultrasonically disperse at 50°C for 60min. to Fe 3 o 4 20mL NaOH solution with a concentration of 8mol / L was added to the suspension, and the lithium-aluminum mixed solution was added dropwise into the reaction kettle at a dropping rate of 5mL / min. The pH at the end of the addition was 4.5. After the reaction was completed, it was aged at 45°C for 2 hours. After the aging, the reaction system was transferred to a polytetrafluoroethylene hydrothermal kettle, and the hydrothermal reaction was carried out at 160°C for 24 hours. The obtai...

Embodiment 2

[0049] Weigh 19.57g AlCl respectively 3 ·6H 2 O and 1.86g LiCl·H 2 O was dissolved in 80mL of deionized water, ultrasonically treated at 60°C for 60 minutes and mixed evenly to prepare a lithium-aluminum mixed solution with Li / Al=0.8 / 2, in which the lithium ion concentration was 0.4mol / L and the aluminum ion concentration was 1.0mol / L. 2.40g Fe prepared by co-precipitation method 3 o 4 Add the solid powder into 100mL deionized water, and ultrasonically disperse at 50°C for 60min. to Fe 3 o 4 20mL NaOH solution with a concentration of 8mol / L was added to the suspension, and the lithium-aluminum mixed solution was added dropwise into the reaction kettle at a dropping rate of 5mL / min. The pH at the end of the addition was 4.5. After the reaction was completed, it was aged at 45°C for 2 hours. After the aging, the reaction system was transferred to a polytetrafluoroethylene hydrothermal kettle, and the hydrothermal reaction was carried out at 160°C for 24 hours. The obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com