Metal-organic framework-based micro-membrane reactor, preparation method and application

A metal-organic framework and reactor technology, used in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve the problems of low loading, small active surface area, etc. Effects of mass and heat transfer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

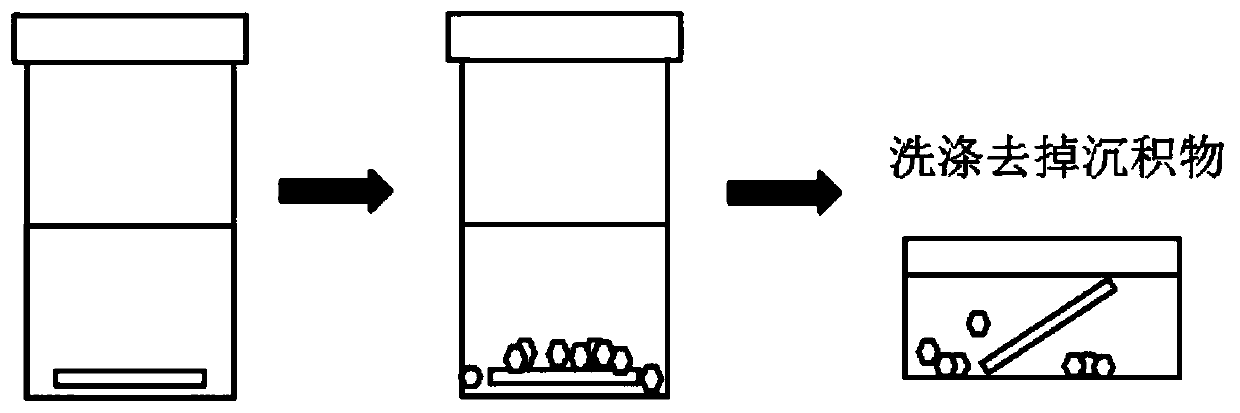

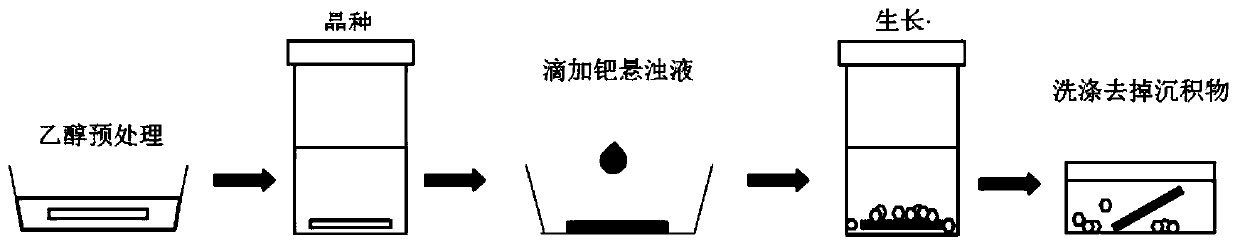

[0034] The invention provides a preparation method of a metal-organic framework-based micro-membrane reactor, which comprises the following steps: preparing a fiber membrane substrate; growing a metal-organic framework membrane on the fiber membrane; and assembling the metal-organic framework membrane into the micro-membrane reactor.

[0035] The metal-organic framework film is prepared by in-situ growth method and secondary growth method, or the noble metal is doped in the metal-organic framework film by an improved secondary growth method. A metal-organic framework-based micro-membrane reactor with tight packaging is obtained by superimposing a cover plate with an inlet and an outlet with a metal-organic framework membrane, and then encapsulating it with polydimethylsiloxane. The rough surface and porous structure of the fibrous substrate can be regarded as microchannels for organic reactions. The fibrous substrate can simultaneously confine the metal-organic framework parti...

Embodiment 1

[0037] Example 1: Preparation of ZIF-8 metal-organic framework membrane on hydrophilic or hydrophobic glass fiber membrane (secondary growth method)

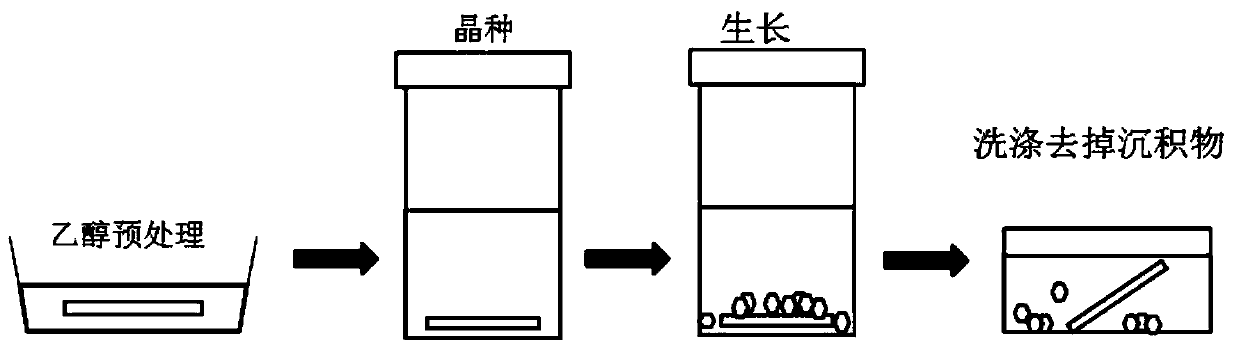

[0038] Place the glass fiber membrane substrate soaked in ethanol in 10 ml of seed crystal solution for 30 minutes at a temperature of 30 degrees. The molar ratio of the seed solution is 1Zn(NO 3 ) 2 ·6H 2 O:70~80 2-Methylimidazole: 5000~6000 water. Then the seeded substrate was washed with water three times, and added to 10 ml of fresh growth solution for 24 hours at 30°C. The molar ratio is 1Zn(NO 3 ) 2 ·6H 2 O:70~80 2-Methylimidazole: 5000~6000 water. Dried glass fiber membranes, without soaking in ethanol, were also treated with the above procedure. The glass fiber membrane was weighed before and after loading ZIF-8 to calculate the loading amount of ZIF-8. Figure 8A Demonstrated the loading of ZIF-8 on a hydrophobic glass fiber membrane; Figure 8B It is the loading of ZIF-8 on the hydrophilic glass fiber membran...

Embodiment 2

[0041] Embodiment 2: Long ZIF-8 metal-organic framework film (secondary growth method) on carbon cloth

[0042] Place the carbon soaked in ethanol in 10ml of seed solution for 30 minutes at a temperature of 30°C. The molar ratio of the seed solution is 1Zn(NO 3 ) 2 ·6H 2 O:70~80 2-Methylimidazole: 5000~6000 water. Then the seeded substrate was washed with water three times, and added to 10 ml of fresh growth solution for 24 hours at 30°C. The molar ratio is 1Zn(NO 3 ) 2 ·6H 2 O:70~80 2-Methylimidazole: 5000~6000 water. The carbon cloth is finally washed with methanol to remove deposits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com