Process for synchronously removing volatile organic chemcials (VOCs), sulfides and ammonia in waste gas and recycling sulfur by chemical biological coupling method

A technology for sulfide and resource utilization, which is applied in the fields of sulfur compounds, chemical instruments and methods, and inorganic chemistry. Carbon source, operating cost saving, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

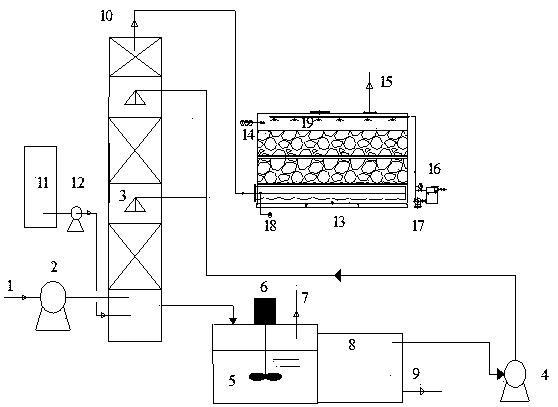

Method used

Image

Examples

Embodiment 1

[0040] Sewage treatment anaerobic process, a 200 t / h papermaking wastewater with an exhaust gas flow of 2500 Nm 3 / h, VOCs content is 600mg / Nm 3 , H 2 The S content is 20000 mg / Nm 3 , NH 3 The content is 500 mg / Nm 3 , the exhaust gas temperature is 30 o C, according to the process of the present invention, when leaving the treatment facility, the VOCs content is ≤ 80 mg / Nm 3 , H 2 S content is ≤35 mg / Nm 3 , NH 3 The content is ≤10 mg / Nm 3 ; The desulfurization efficiency is over 98%, the denitrification efficiency is over 98%, the VOCs removal efficiency is over 85%, and the recovery of elemental sulfur is 1200 kg / d. The absorption tower is a spray tower with a diameter of 1.5 m, a height of 12 m, and a liquid-gas ratio of 6 L / Nm 3 In the absorption process, the desulfurization and denitrification absorption liquid is mixed with water-soluble alkalis and salts to form a buffer solution, which is mainly alkalis or salts of group IA or IIA elements, preferably sodium h...

Embodiment 2

[0042] Mixed gas from pharmaceutical workshops and anaerobic tanks with an exhaust gas flow of 4000 Nm 3 / h, H 2 The S content is 30000 mg / Nm 3 , NH 3 The content is 400 mg / Nm 3 , VOCs content is 800 mg / Nm 3 , the exhaust gas temperature is 35°C, according to the process of the present invention, when the exhaust gas leaves the absorption tower, H 2 S content is ≤50 mg / Nm 3 , NH 3 The content is ≤20 mg / Nm 3 , VOCs content is ≤80 mg / Nm 3 , the removal efficiency of VOCs is over 90%, the desulfurization efficiency is over 98%, the denitrification efficiency is over 98%, and the recovery of elemental sulfur is 2700 kg / d. The absorption tower is a packed tower with a diameter of 2.0 m, a height of 18 m, and a liquid-gas ratio of 6 L / Nm 3 The lye of the absorption liquid in the absorption process is preferably a mixture of water-soluble alkalis and salts to form a buffer solution, mainly alkalis or salts of IA or IIA group elements, preferably sodium hydroxide, calcium hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com