Greenhouse crop planting automated operation all-in-one machine

A technology of crops and all-in-one machines, applied in agriculture, planting methods, sowing seeders, etc., can solve the problems of poor planting effect of greenhouse vegetables, high labor intensity, and damage to workers' waists, so as to improve economic practicability, economic efficiency, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

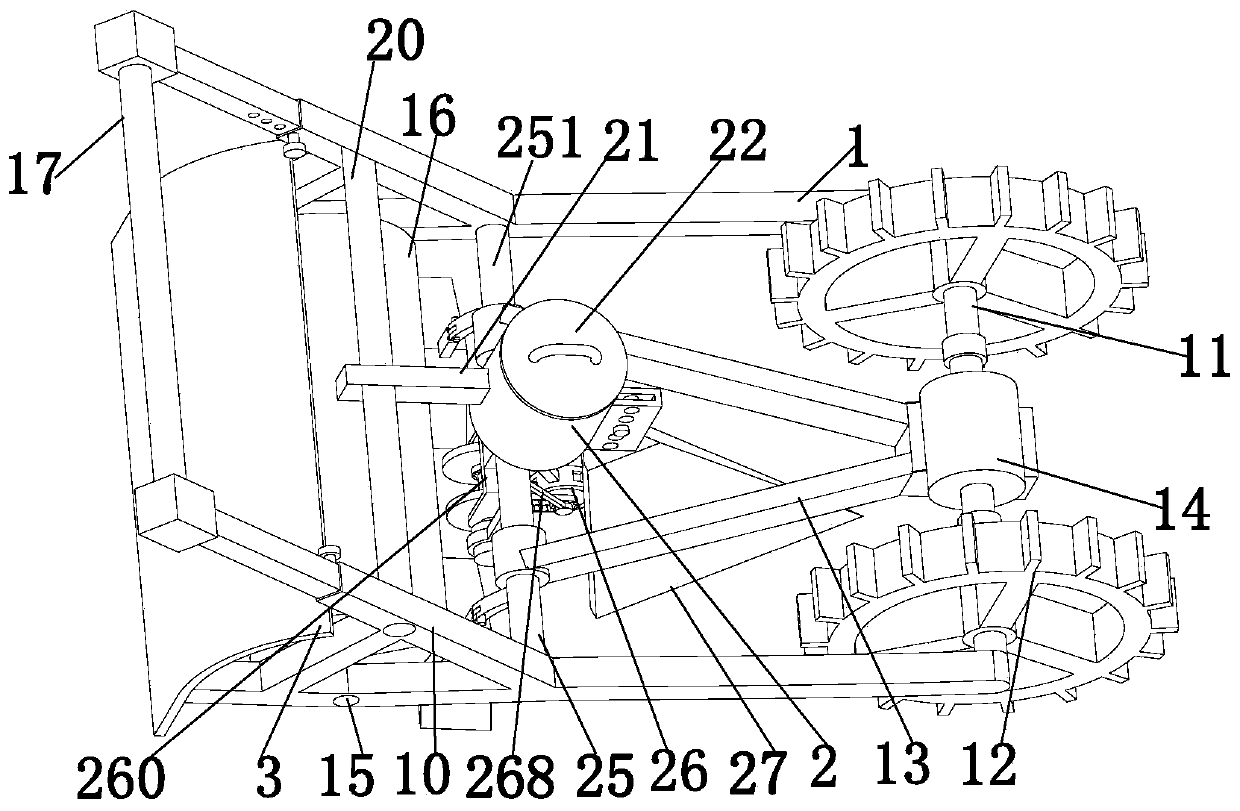

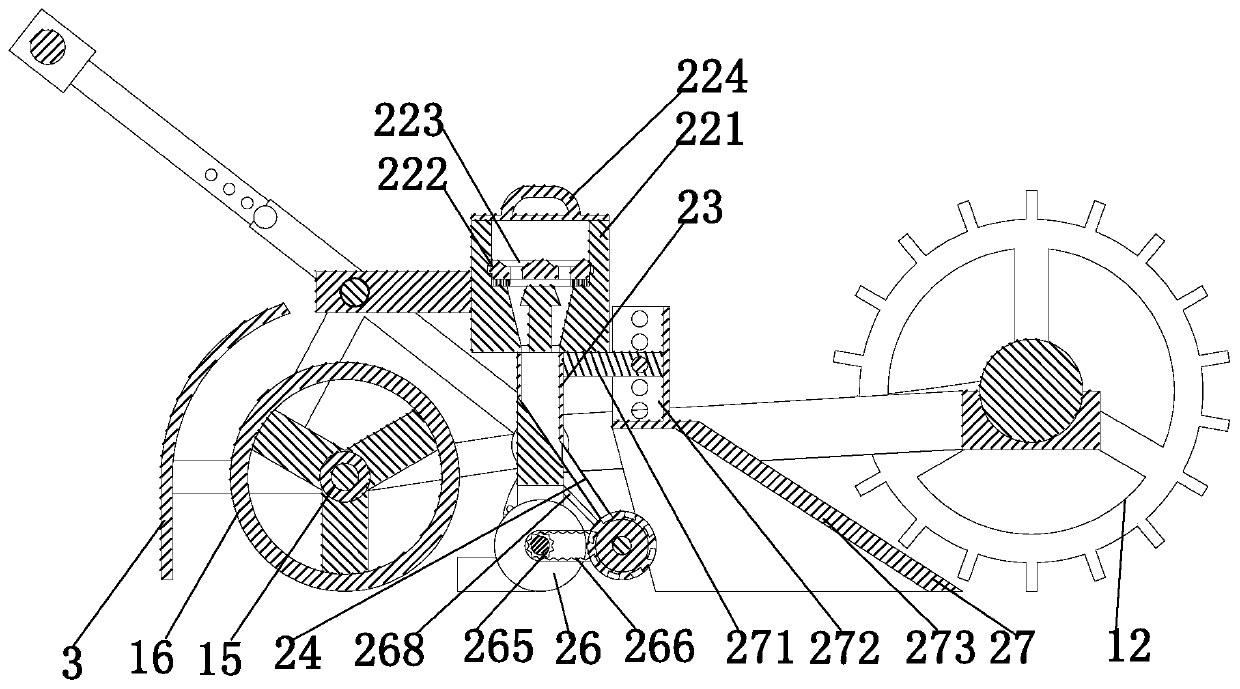

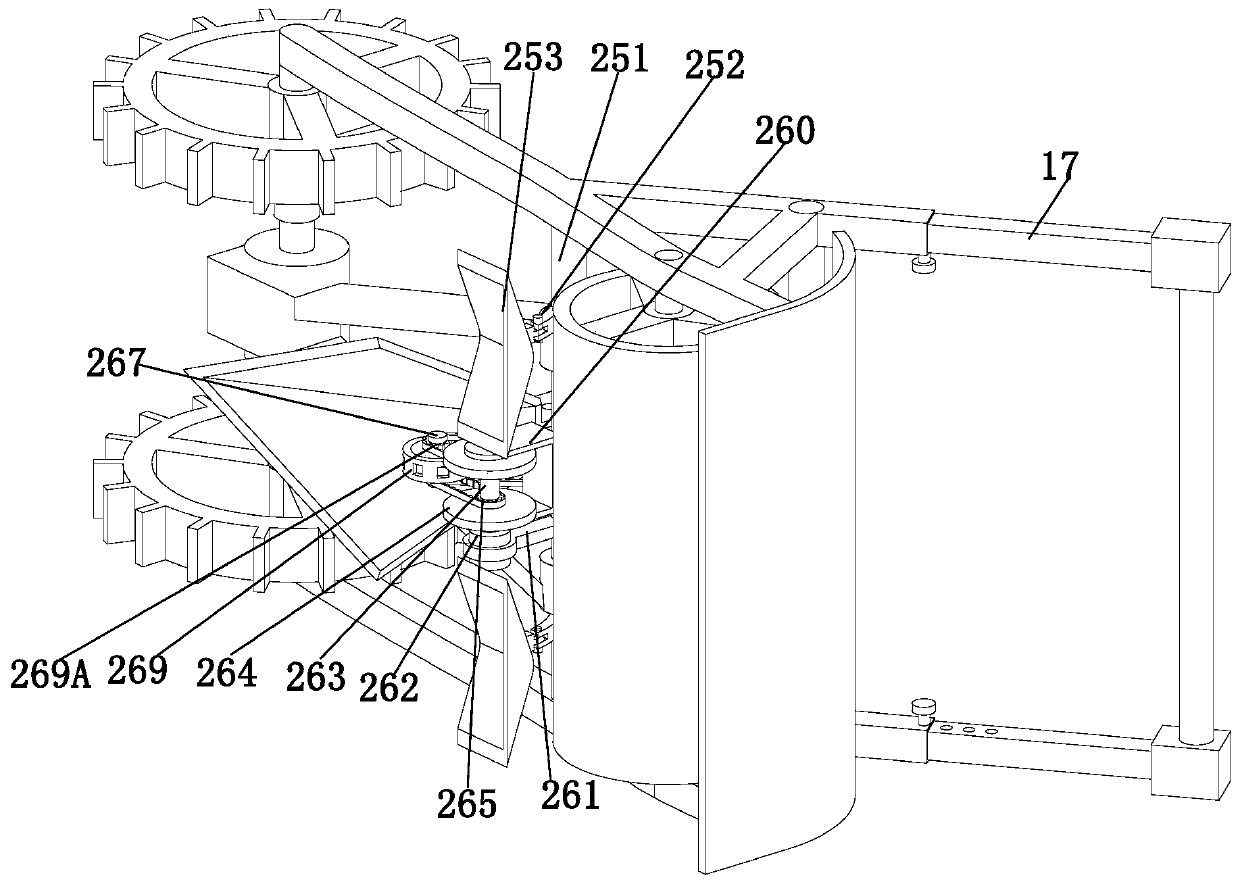

[0025] Such as Figure 1 to Figure 3 As shown, a greenhouse crop planting automatic operation integrated machine includes a driving device 1, an executing device 2 and a protective baffle 3, the middle of the driving device 1 is provided with an executing device 2, and the protective baffle 3 is installed On the device 1, and the protective baffle 3 is located at the rear of the actuator 2, the protective baffle 3 is an inner arc-shaped structure, and the protective baffle 3 is set as an inner arc-shaped structure to prevent soil from splashing during the sowing operation. It also prevents the operator from colliding with the machine by mistake during sowing operations to prevent accidents and improve work safety; among them:

[0026]Described driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com