Cord-driven two-degree-of-freedom electromagnetic energy harvester

A degree of freedom, electromagnetic technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing the output power, large energy loss, and low output power of the energy harvester, so as to alleviate the resonance frequency mismatch and reduce the Energy loss, effects for a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

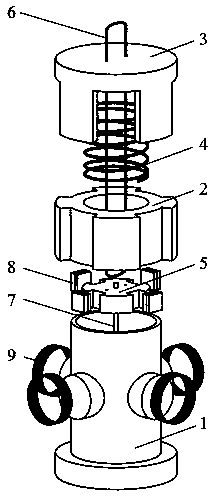

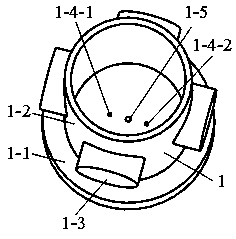

[0031] like figure 1 , figure 2 , Figure 7 A two-degree-of-freedom electromagnetic energy harvester driven by a wire is shown, at least including a base 1, a support cylinder 2, a top cover 3, a spring 4, a rotor 5, a wire 6, a guide rod 7, four magnets 8, four a coil 9; the support cylinder 2 includes a large counterbore 2-1, a small counterbore 2-2 and four support cylinder grooves 2-3; the large counterbore 2-1 is located on the bottom surface of the support cylinder 2, and The support cylinder 2 is coaxial; the small counterbore 2-2 is located on the top surface of the support cylinder 2 and is coaxial with the support cylinder 2; the four support cylinder grooves 2-3 are evenly distributed on the side of the support cylinder 2; The lower end of the spring 4 is fixedly connected to the small counterbore 2-2 of the support column 2, and the large counterbore 2-1 of the support column 2 is overlaid on the cylinder 1-2 of the base 1, and the spring 4 is connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com