A two-degree-of-freedom piezoelectric-electromagnetic hybrid energy harvester

An energy harvester and hybrid technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., which can solve the problem of low output power and inability to efficiently collect low-frequency vibration energy, etc. problem, to achieve the effect of large output power, simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

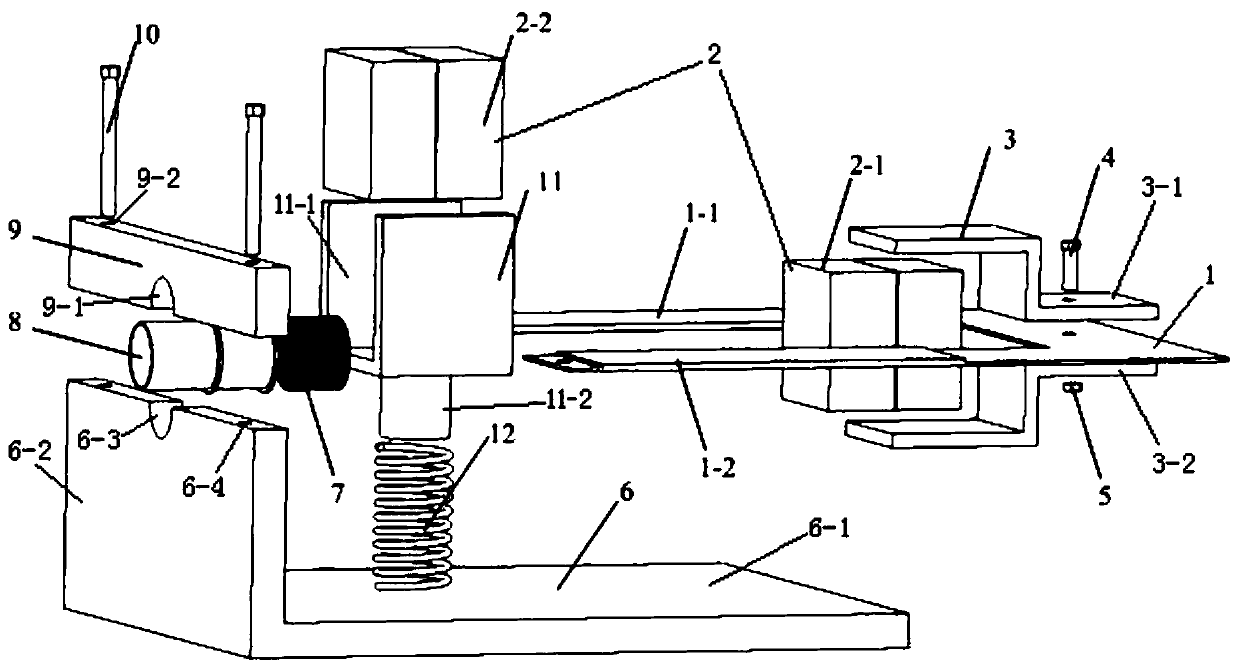

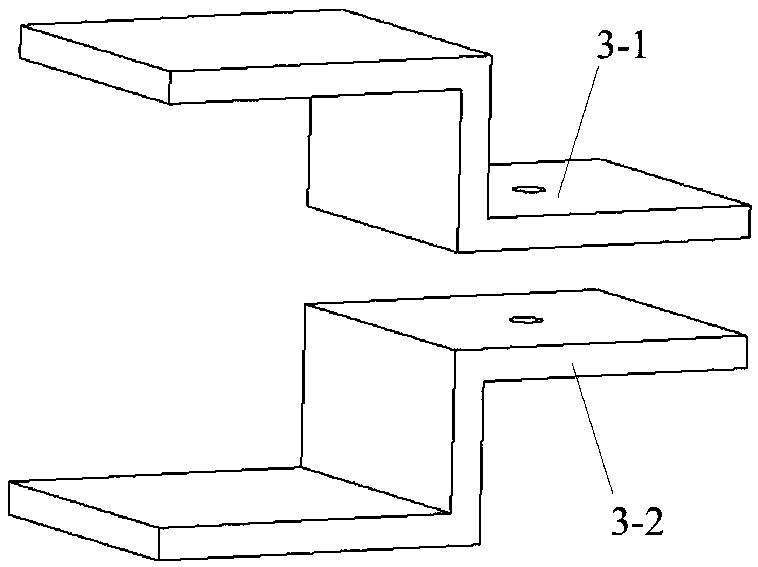

[0030] see figure 1, the present invention provides a two-degree-of-freedom piezoelectric-electromagnetic hybrid energy harvester, which at least includes a U-shaped cantilever beam 1, a magnet 2, a detachable clamp 3, a frame 6, a coil 7, a cylinder 8, and a fixed clamp 11 , spring 12; The magnet 2 includes a first magnet 2-1 and a second magnet 2-2; The frame 6 includes a bottom plate 6-1 and a vertical wall 6-2 that are firmly connected together; The U-shaped The cantilever beam 1 is composed of a first piezoelectric cantilever beam 1-1 and a second piezoelectric cantilever beam 1-2. The open end of the U-shaped cantilever beam 1 is fixedly connected to the vertical wall 6-2 of the frame 6. The piezoelectric cantilever beam 1-1 and the second piezoelectric cantilever beam 1-2 are parallel in the horizontal plane, and the free end of the U-shaped cantilever beam 1 is fixedly connected to the first magnet 2-1 through a detachable clamp 3. A magnet 2-1 is located between the ...

Embodiment 2

[0032] On the basis of Embodiment 1, the open end of the U-shaped cantilever beam 1 is fixedly connected to the vertical wall 6 - 2 of the frame 6 through the cover plate 9 and the screw 10 .

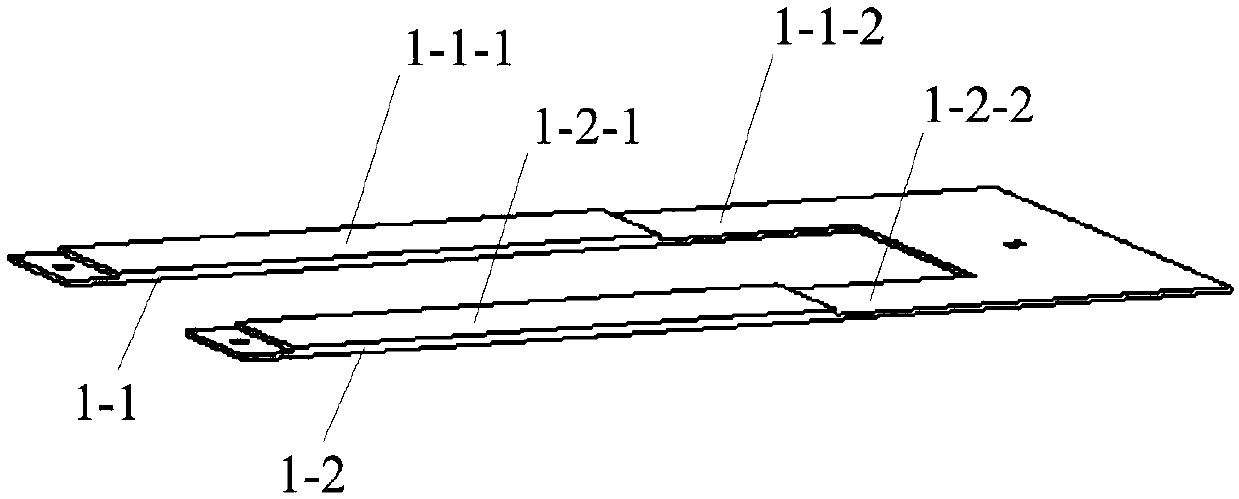

[0033] like figure 2 As shown, the first piezoelectric cantilever 1-1 includes a first piezoelectric element 1-1-1 and a first rectangular piezoelectric metal beam 1-1-2; the second piezoelectric cantilever 1- 2 includes a second piezoelectric element 1-2-1 and a second rectangular piezoelectric metal beam 1-2-2; the first piezoelectric element 1-1-1 is fixed to the first rectangular piezoelectric On the metal beam 1-1-2, the second piezoelectric element 1-2-1 is fixed on the second rectangular piezoelectric metal beam 1-2-2 through conductive glue; the first piezoelectric element 1-1 -1 is polarized along the thickness direction of the first rectangular piezoelectric metal beam 1-1-2, and the electrodes of the first piezoelectric element 1-1-1 are connected in series or in parallel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com