Two-dimensional piezoelectric electromagnetic hybrid energy harvester

A hybrid energy harvester technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of low output power and achieve high output power, High energy harvesting efficiency, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

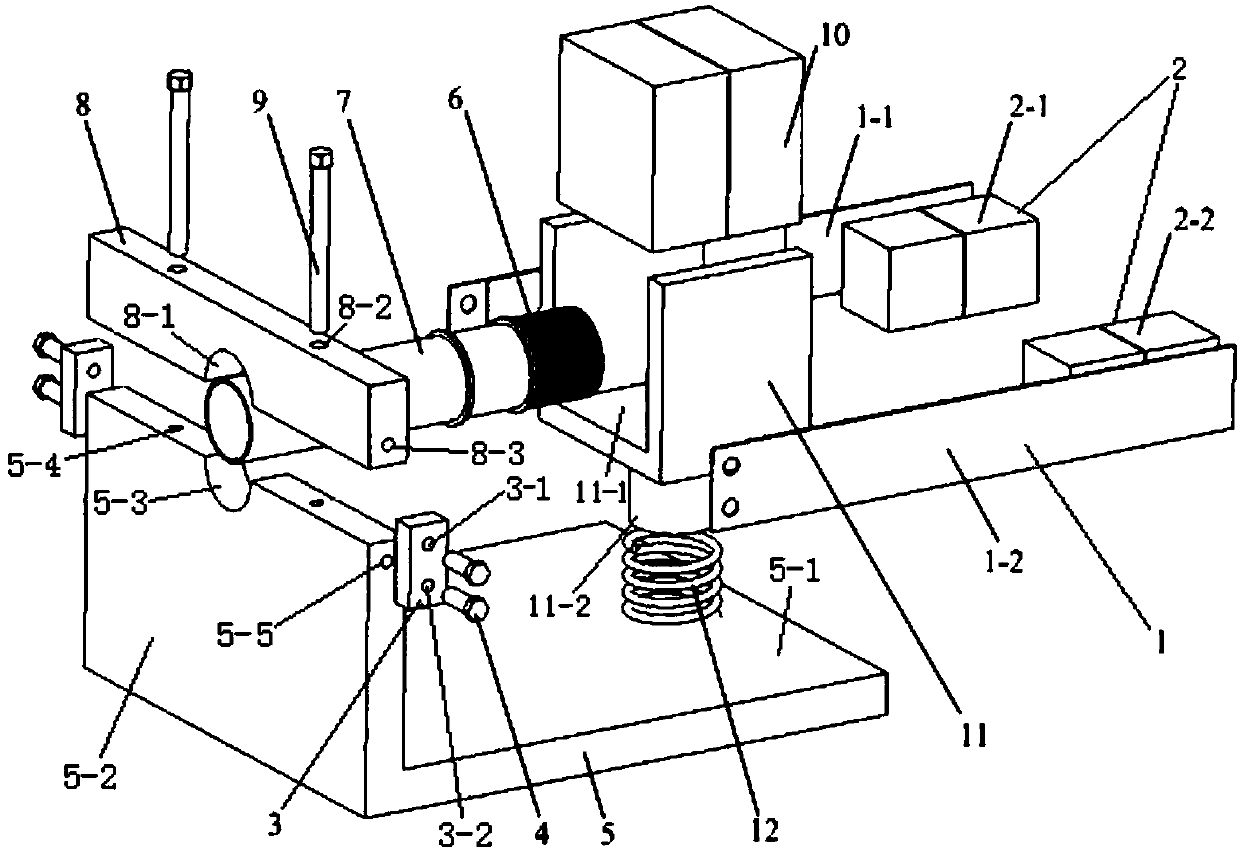

[0031] Such as figure 1 As shown, the present invention provides a two-dimensional piezoelectric electromagnetic hybrid energy harvester, which at least includes a piezoelectric cantilever beam 1, a magnet 2, a frame 5, a coil 6, a cylinder 7, a fixed fixture 11, and a spring 12; The magnet 2 includes a first magnet 2-1 and a second magnet 2-2; the frame 5 includes a bottom plate 5-1 and a vertical wall 5-2 that are fixed together; the piezoelectric cantilever beam 1 includes a first A piezoelectric cantilever 1-1 and a second piezoelectric cantilever 1-2, the fixed end of the first piezoelectric cantilever 1-1 is fixedly connected to the rear end of the vertical wall 5-2, the The fixed end of the second piezoelectric cantilever beam 1-2 is fixedly connected to the rear end of the vertical wall 5-2, the free end of the first piezoelectric cantilever beam 1-1 is fixedly connected to the first magnet 2-1, The free end of the second piezoelectric cantilever 1-2 is fixedly connec...

Embodiment 2

[0033] On the basis of Embodiment 1, the first piezoelectric cantilever beam 1 - 1 and the second piezoelectric cantilever beam 1 - 2 are fixedly connected to the vertical wall 5 - 2 of the frame 5 through the splint 3 and the screw 4 respectively.

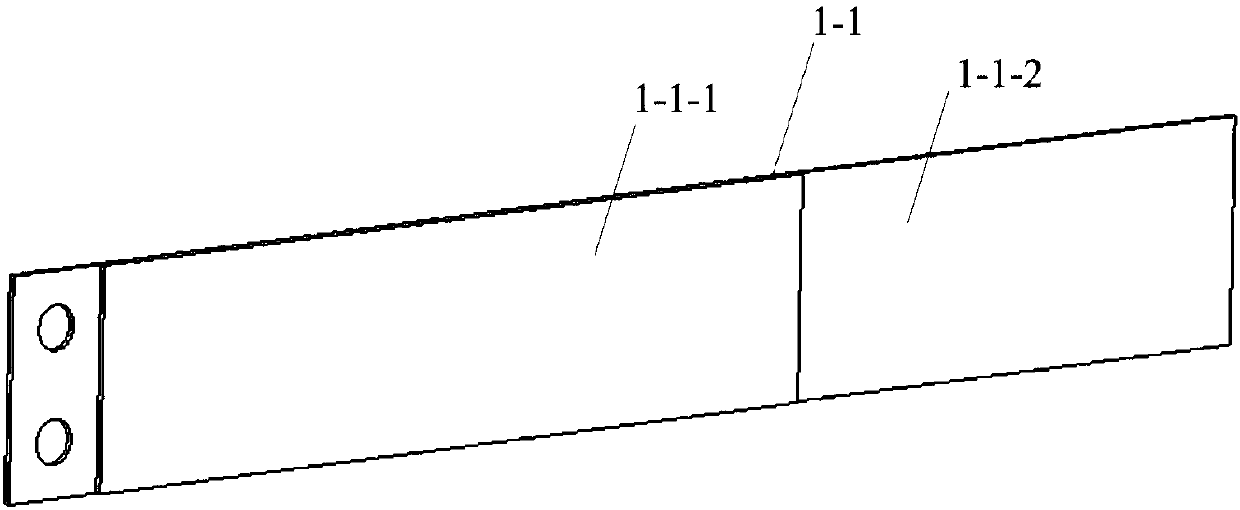

[0034] Such as figure 2 As shown, the first piezoelectric cantilever beam 1-1 includes a piezoelectric element 1-1-1 and a rectangular piezoelectric metal beam 1-1-2; the piezoelectric element 1-1-1 is fixed by conductive glue on the rectangular piezoelectric metal beam 1-1-2; the piezoelectric element 1-1-1 is polarized along the thickness direction of the rectangular piezoelectric metal beam 1-1-2, and the piezoelectric element 1-1-1 The electrodes are connected in series or in parallel; the structure of the second piezoelectric cantilever beam 1-2 is the same as that of the first piezoelectric cantilever beam 1-1.

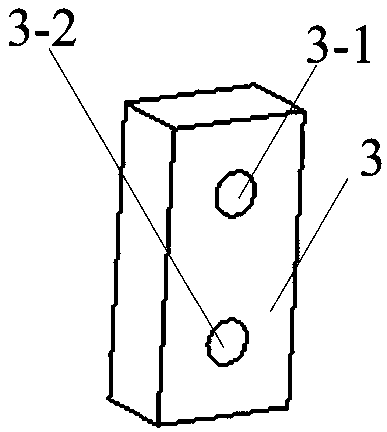

[0035] Such as image 3 As shown, the splint 3 is a rectangular sheet structure, and the splint 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com