Organic metal halide perovskite solar cell composite packaging thin film and preparation method thereof

A halide perovskite, solar cell technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as damage to perovskite solar cell devices, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

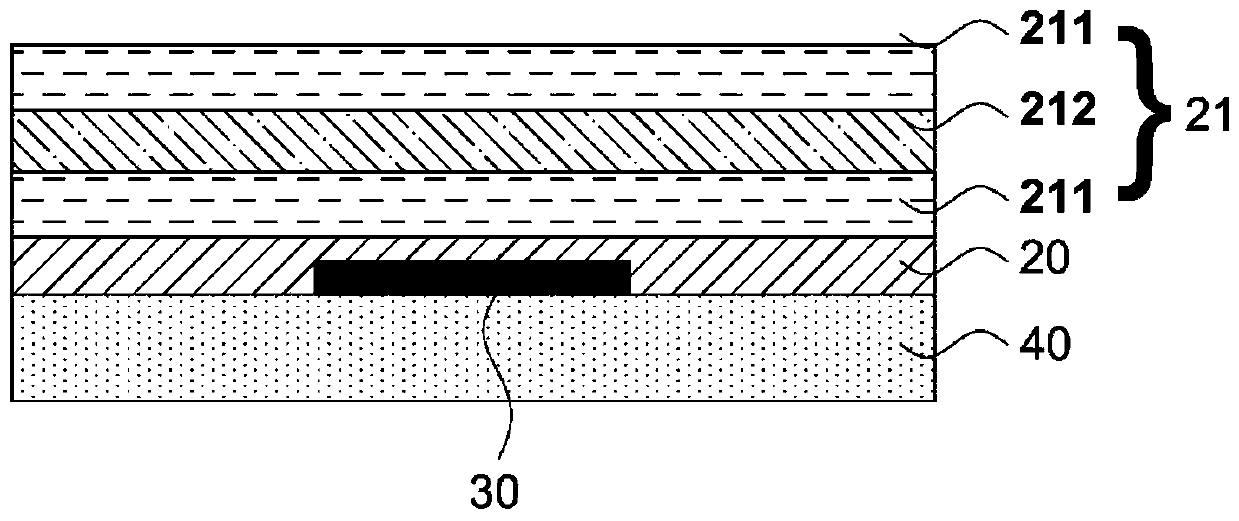

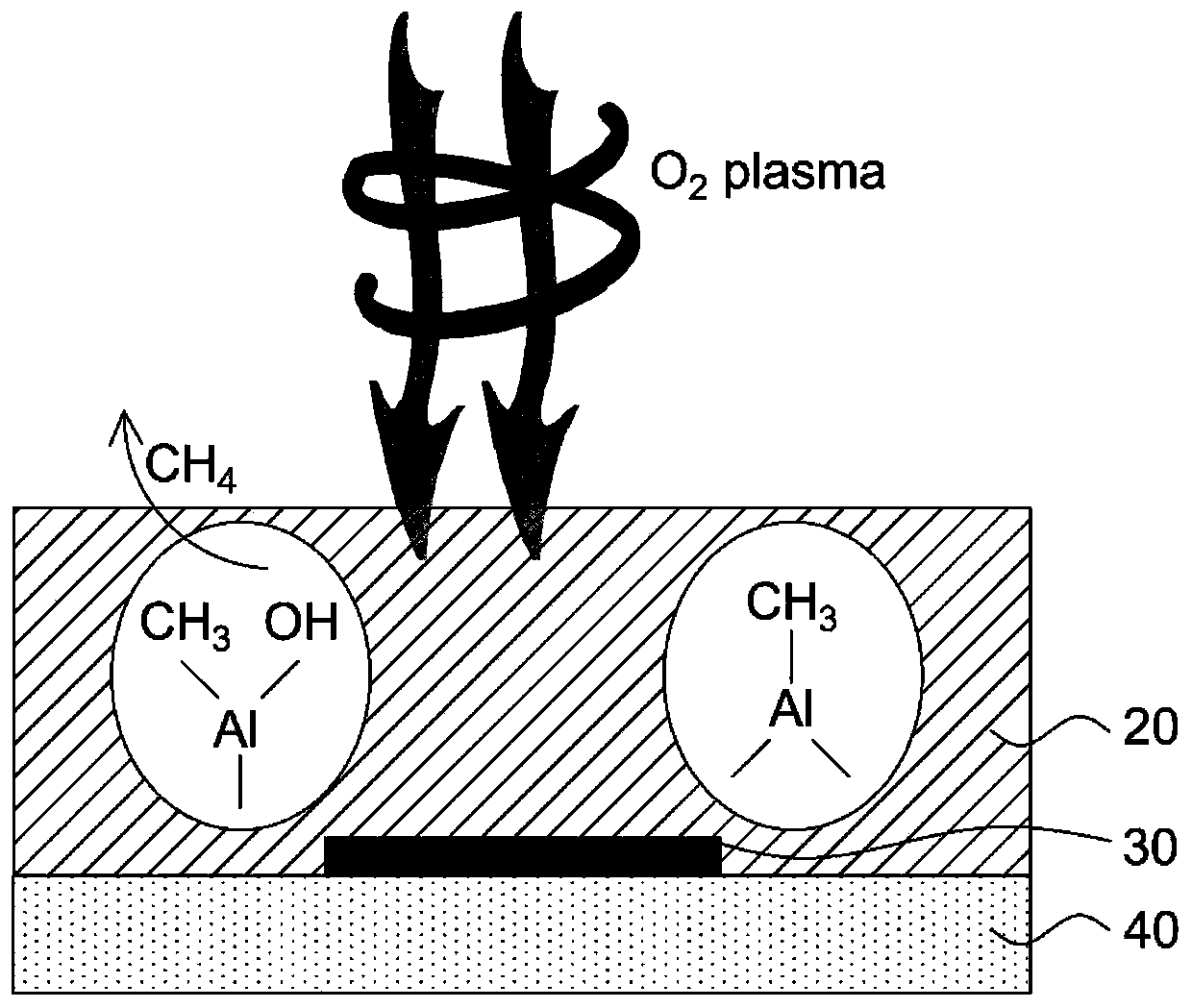

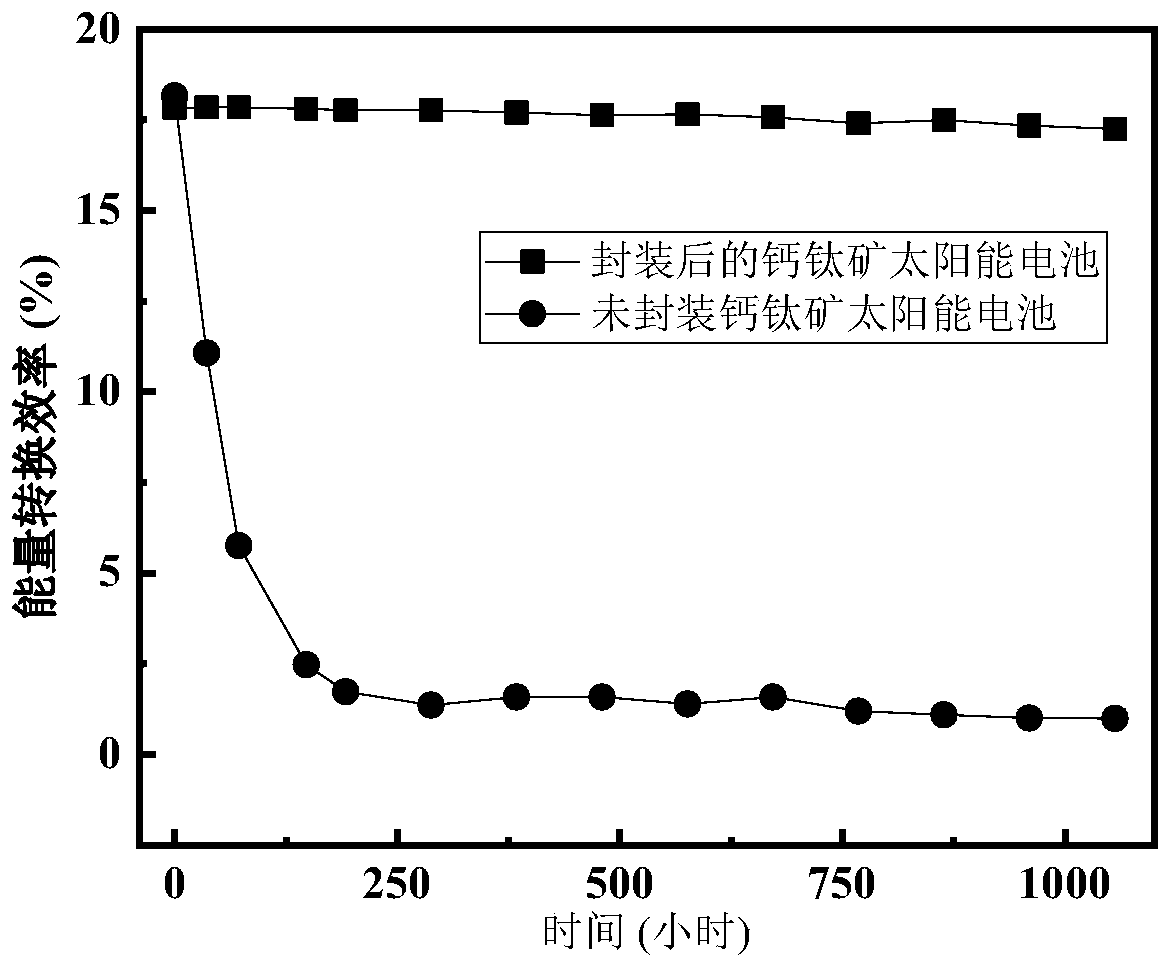

[0050] refer to figure 1 As shown, Embodiment 1 of the present invention provides a thin film encapsulation structure of an organometal halide perovskite solar cell prepared on a rigid substrate, the structure comprising a rigid substrate 40, an organometal halide perovskite disposed on the substrate Mineral solar cell 30, an organic-inorganic hybrid barrier layer 20 disposed on the outer surface of the organometal halide perovskite solar cell 30 and used to protect the perovskite solar cell 30 during packaging and practical application, and disposed on the hybrid Composite barrier layer 21 on the barrier layer 20 and used to protect the perovskite solar cell 30 during practical application.

[0051] Wherein, the rigid substrate 40 is a glass substrate, and the perovskite solar cell 30 is a planar organic metal halide perovskite solar cell (ITO / SnO 2 / MaPbI 3 / spiro-MeOTAD / Ag, Li, F.; Liu, M., Recent efficient strategies for improving the moisture stability of perovskite sol...

Embodiment 2

[0063] refer to Figure 4 As shown, the present embodiment provides a thin film encapsulation structure of a perovskite solar cell on a flexible substrate, the structure includes a flexible substrate 40, a substrate disposed on the substrate for protecting the perovskite solar cell 30 during practical application Encapsulation barrier layer 22, the perovskite solar cell 30 disposed on the base encapsulation barrier layer 22, the organic-inorganic hybrid barrier layer 20 disposed on the device 30 and used to protect the perovskite solar cell 30 during the encapsulation process, The top packaging composite barrier layer 21 is disposed on the hybrid barrier layer 20 and used to protect the device 30 during practical application. Wherein, the top packaging composite barrier layer 21 includes at least two inorganic barrier layers 211 and at least one organic barrier layer 212 disposed between two adjacent inorganic barrier layers.

[0064] The flexible substrate 40 is PET, which has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com