Building floor heat insulation structure

A technology of floor and thermal insulation layer, which is applied in the direction of floor, building structure, covering/lining, etc., can solve the problems of rough treatment of the ground floor, the flatness cannot meet the construction conditions of the thermal insulation layer, and the hollowing and cracking of the protective layer. To achieve the effect of increasing floor height, convenient process and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

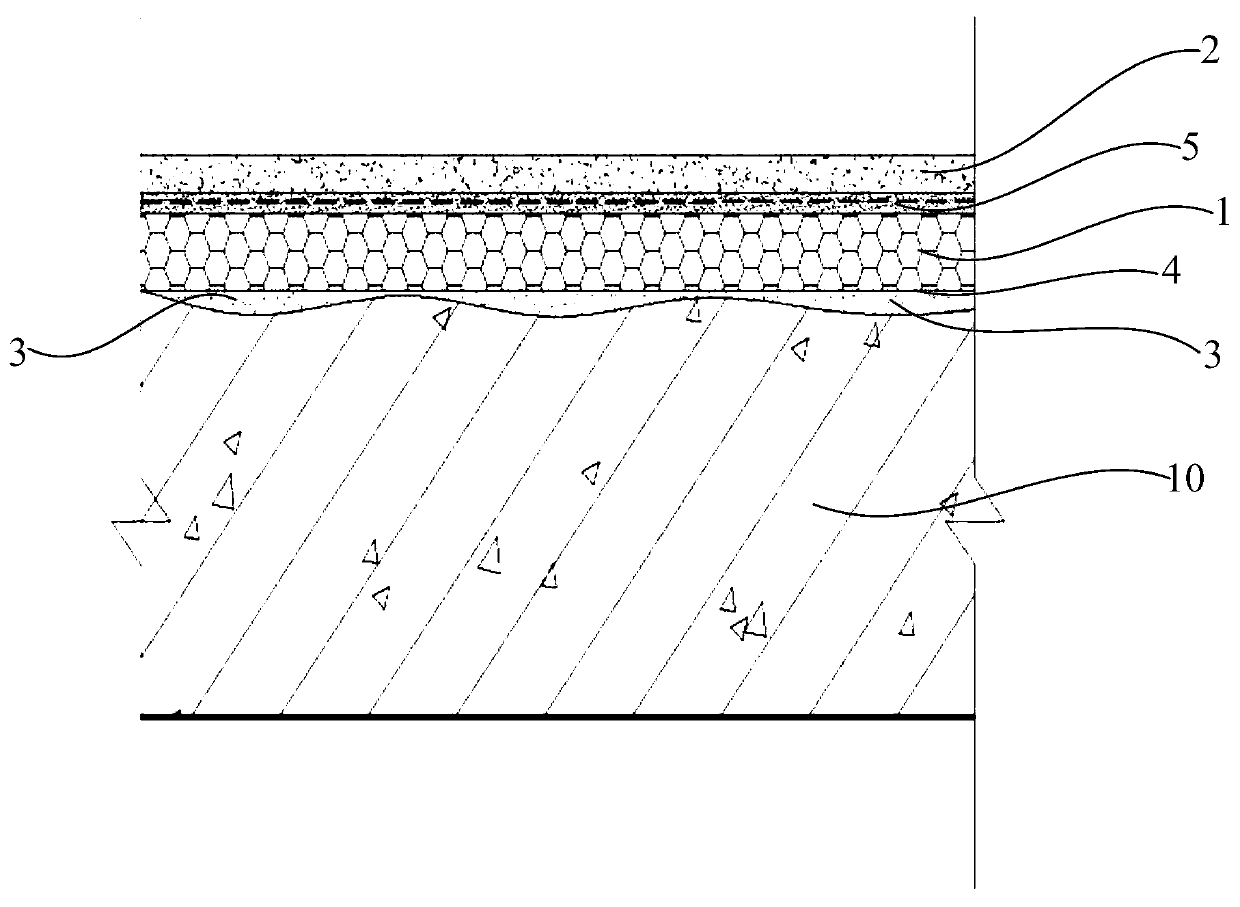

[0026] Such as figure 1 As shown, this embodiment discloses a floor insulation structure. The floor insulation structure includes an insulation layer 1, an armor layer 2 and a leveling layer 3. The armor layer 2 is arranged above the insulation layer 1, and the leveling layer 3 is used for It is connected to the base layer 10 of the floor, and the leveling layer 3 is arranged below the thermal insulation layer 1 . Lay the leveling layer 3 on the base layer 10 of the floor, and realize the leveling of the base layer 10 through the leveling layer 3, and then lay the insulation layer 1 on the top of the leveling layer 3, so as to avoid the unevenness of the original base layer after laying the insulation layer 1 on the base layer 10 of the building. And form the cavity with the insulation layer 1, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com