Preparation method of combustible mud from urban sludge and firecoal

An urban sludge, coal-burning technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as large heat consumption, limitation, insecurity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

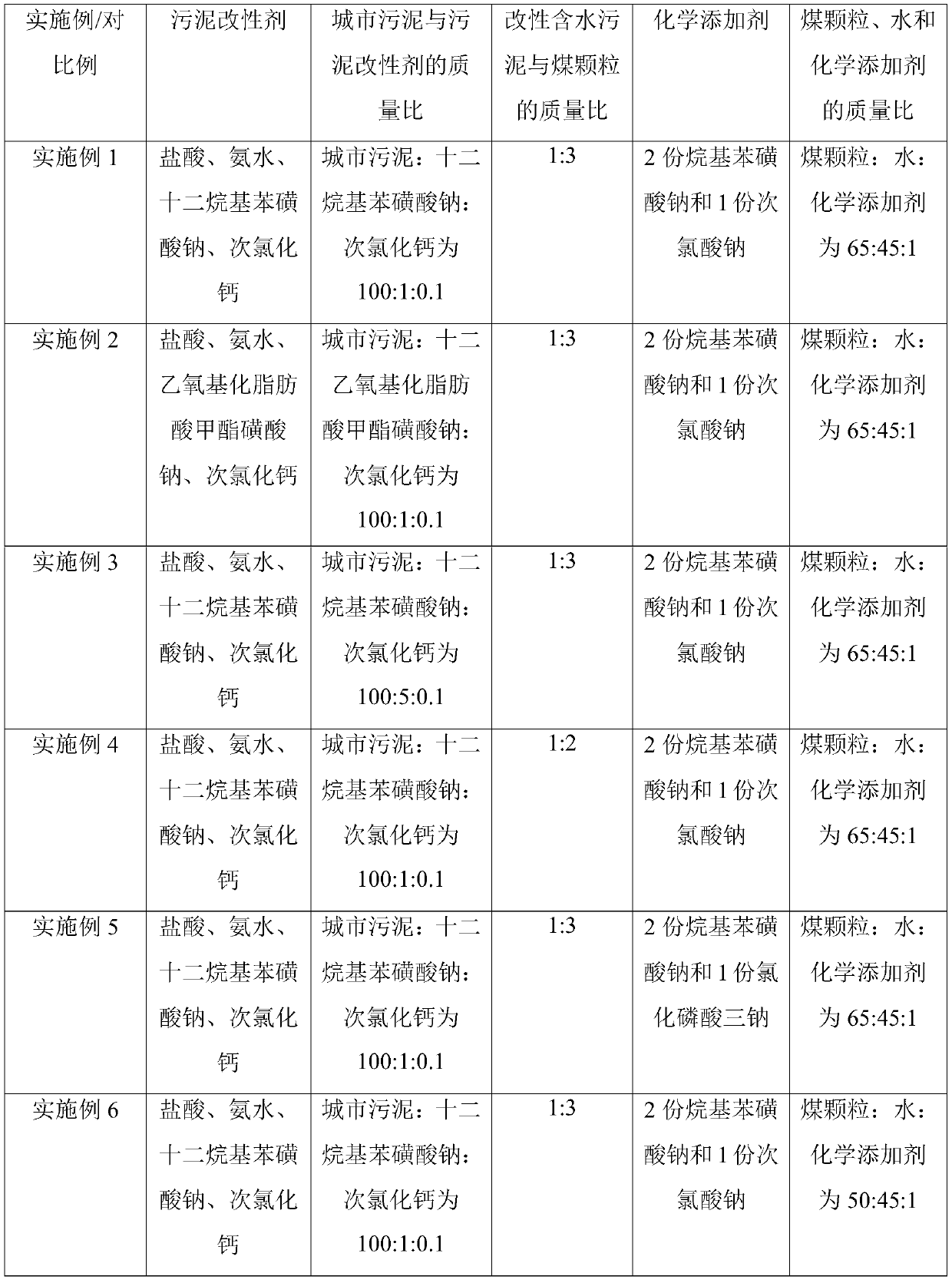

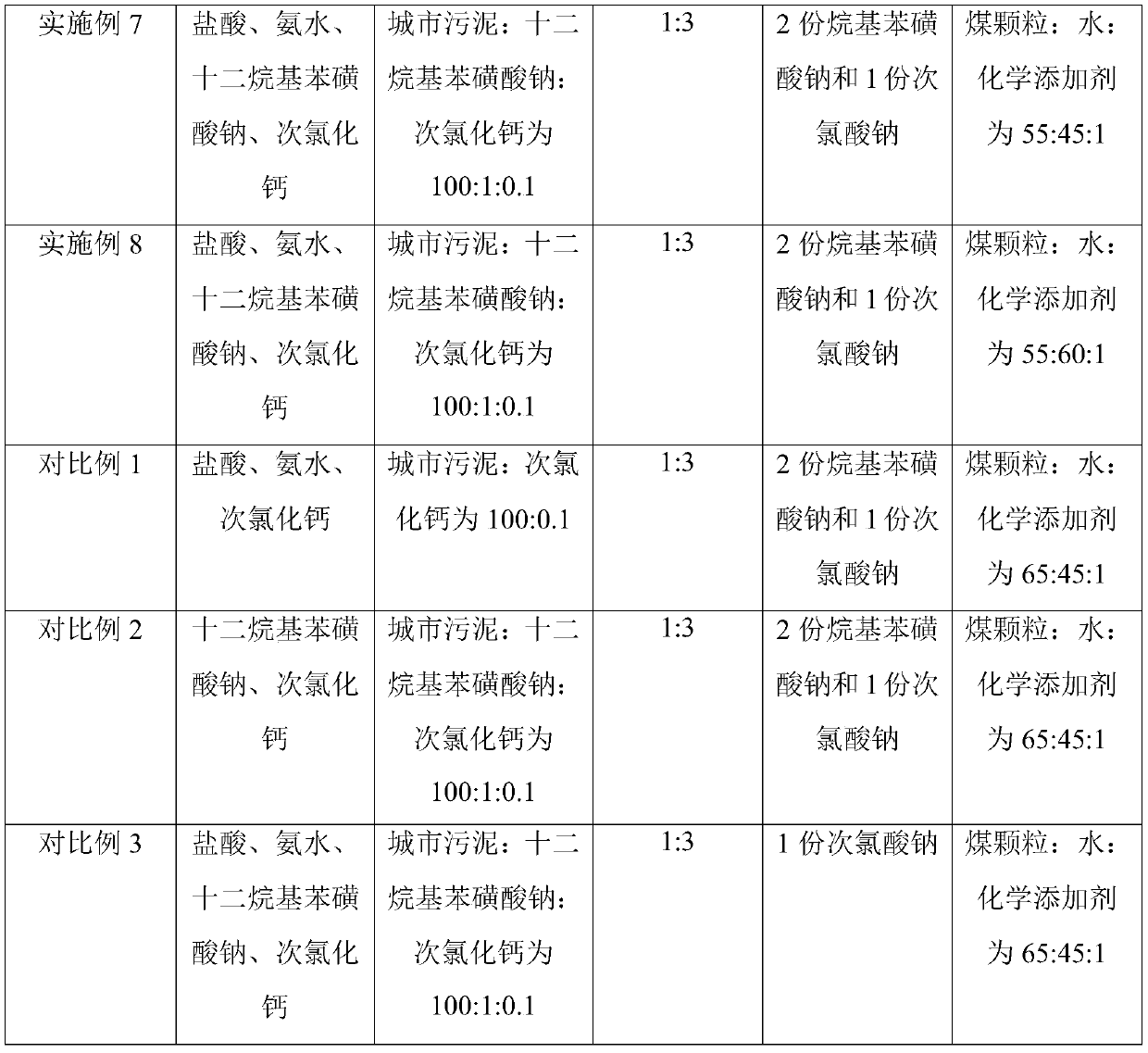

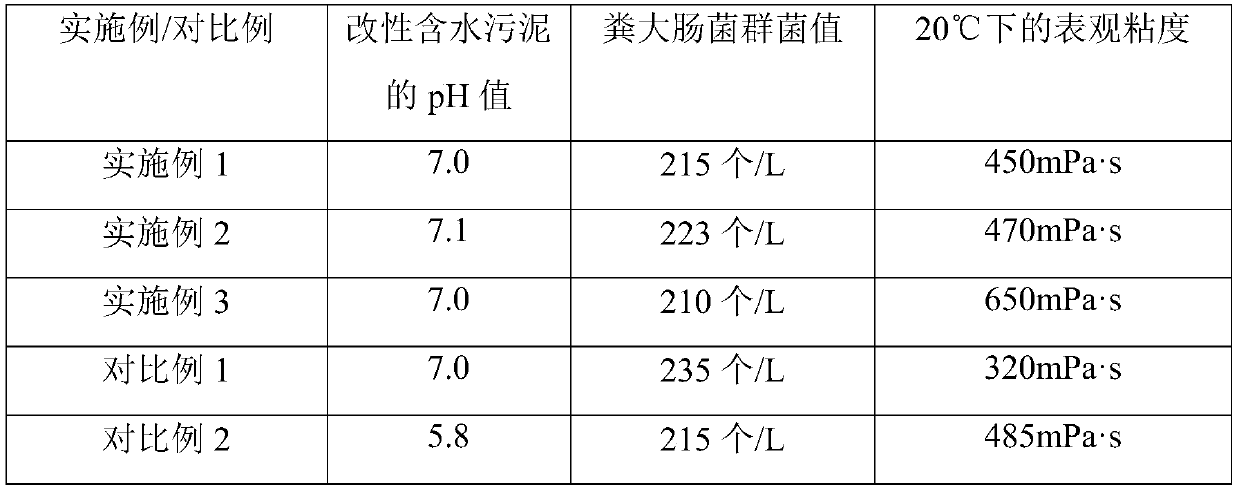

Examples

Embodiment 1

[0051] A method for preparing combustible sludge from municipal sludge and burning coal includes the following steps:

[0052] (1) Preparation of modified aqueous sludge

[0053] Mix municipal sludge with sludge modifier in a 200m3 storage tank. The sludge modifier includes hydrochloric acid, ammonia, sodium dodecylbenzene sulfonate and calcium hypochloride, and municipal sludge and dodecylbenzene The mass ratio of sodium sulfonate and calcium hypochloride is 100:1:0.1.

[0054] The constant temperature system is used to control the temperature in the tank at 15-20°C; the grouped mechanical shearing and stirring are used to ensure the formation of the sludge in the tank while the heavy metals separate and settle.

[0055] (2) Material handling

[0056] The fluid state of the modified water-containing sludge is transported to the ball mill, and the coal in the coal bunker (15%-18% of the total water received) is crushed into particles with a particle size of 1~5mm. The modified water-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com