Silicone tube production line and process

A silicone tube and production line technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of increased production costs, complicated operating procedures, and high equipment costs, and achieves reduced floor space, simplified operating procedures, and reduced The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

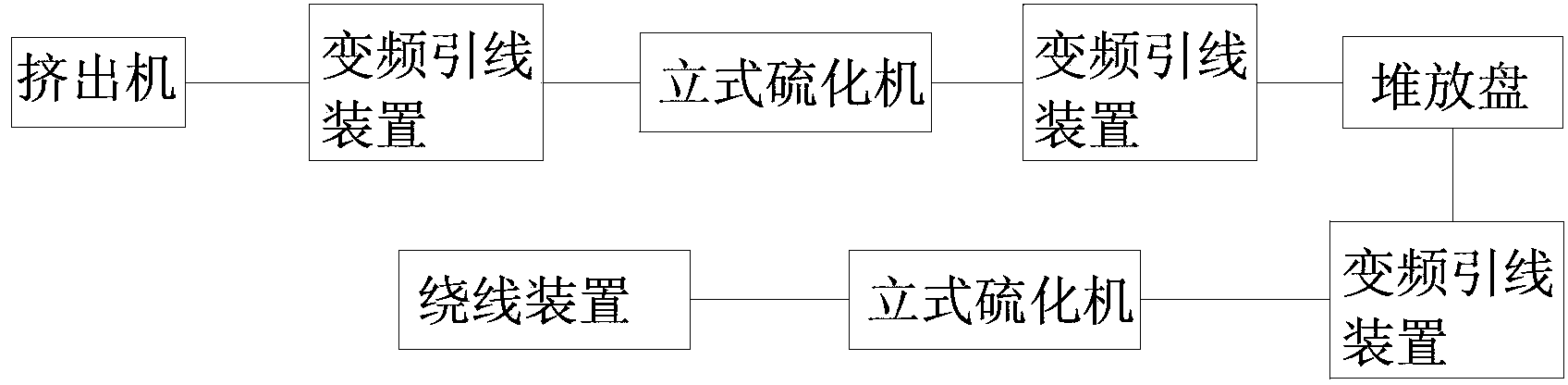

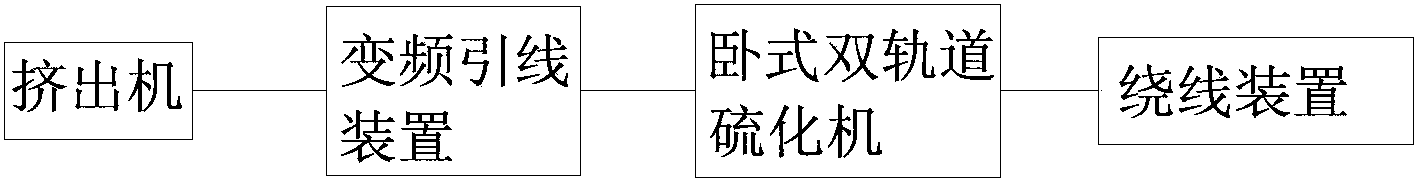

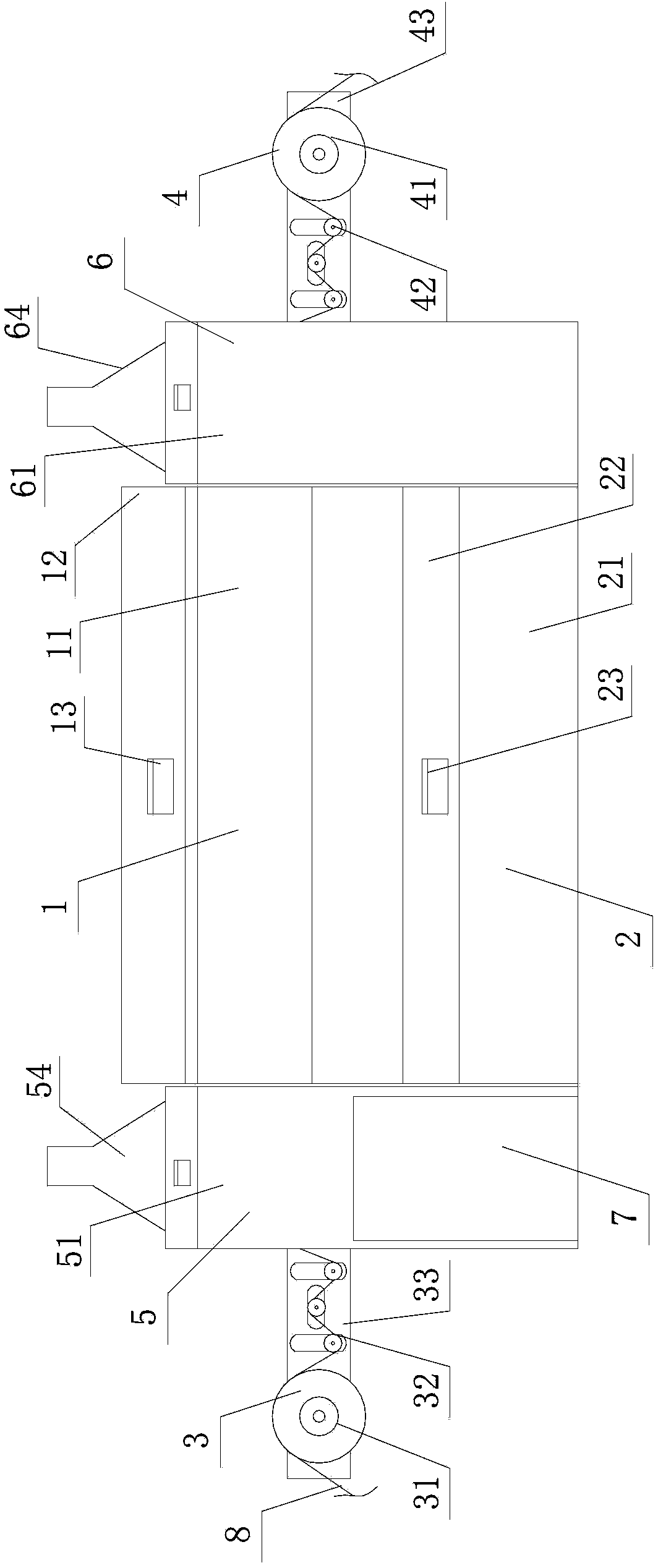

[0061] like Figure 2-6 As shown, the silicone tube production line described in this embodiment includes an extruder, a frequency conversion lead wire device, a horizontal double track vulcanizer and an automatic winding device arranged in sequence, wherein the horizontal double track vulcanizer includes an up and down connection The upper vulcanization box 1 and the lower vulcanization box 2 are set for vulcanizing the silicone tube 8, and both sides of the horizontal double track vulcanizer are set to make the silicone tube 8 inside the upper vulcanization box 1 and the lower vulcanization box 2 cyclic motion transmission.

[0062] The upper vulcanization box 1 comprises a first box body 11, a first cover body 12 is arranged on the first box body 11, a first handle 13 is set on the first cover body 12, to facilitate opening of the first cover body 12, the first box body The first inlet 17 and the first outlet 18 are arranged at both ends of 11 respectively, and the vulcani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com