Completely recoverable barrier PE membrane material as well as preparation method and application thereof

A technology of barrier property and film material, applied in the field of organic packaging film materials, can solve the problems of poor barrier property of pure PE film material, inability to effectively protect the contents, and rapid film leakage, and achieve good transparency, good printing adaptability, and economical efficiency. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

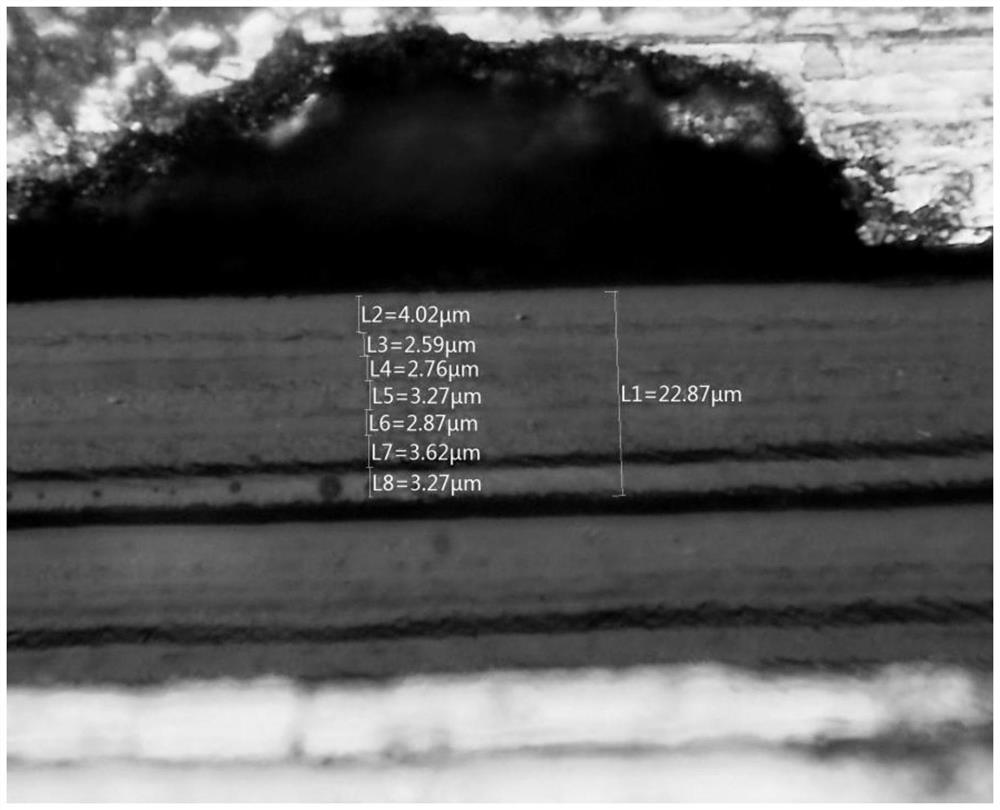

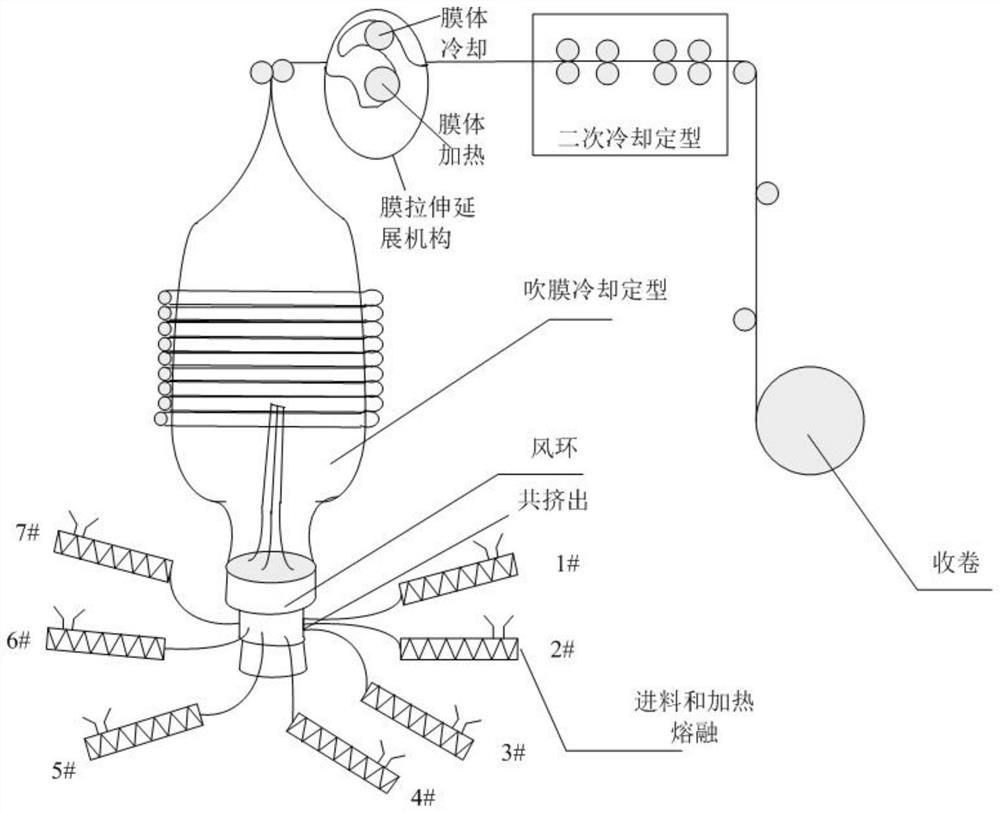

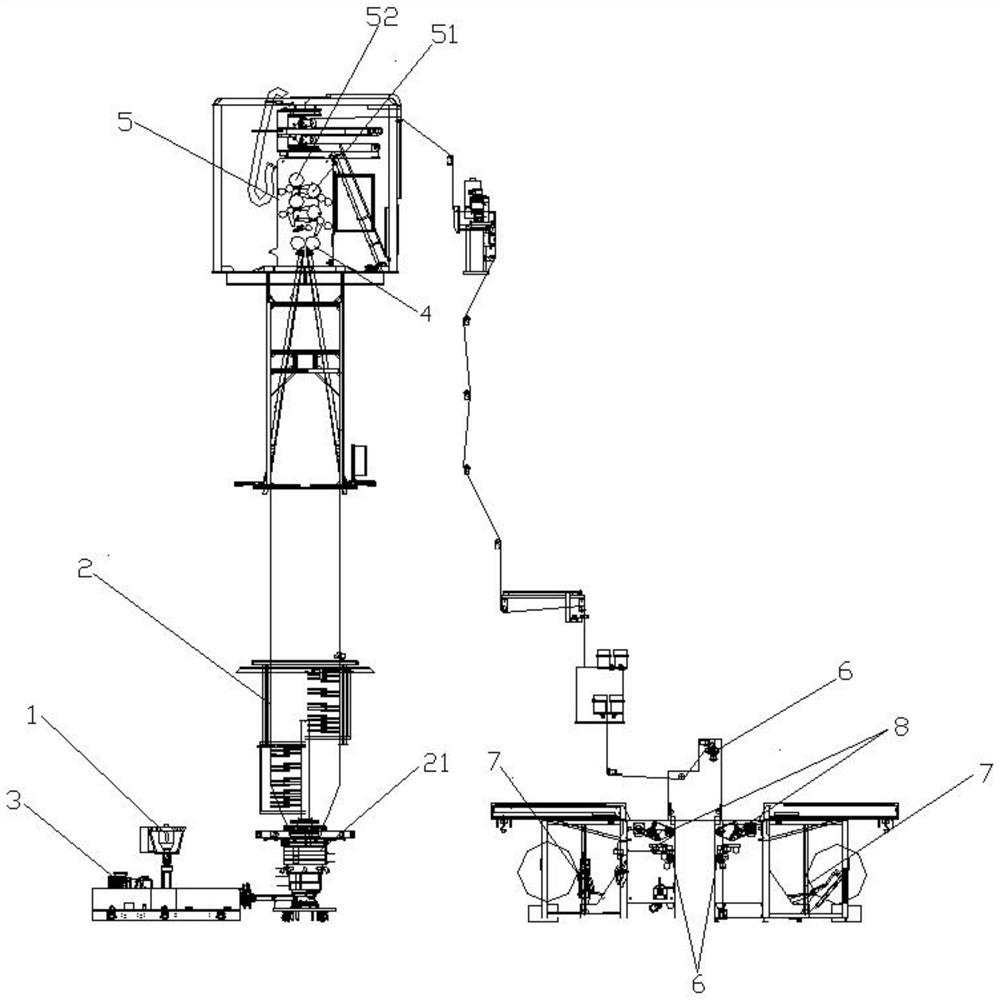

[0070] such as figure 1 The fully recyclable barrier PE film material of the present invention as shown comprises seven superimposed film layer structures, the substrates of each film layer in the film layer structure are polyethylene polymer materials (PE), and the film layer structure It contains three-layer HDPE functional layer with high-density polyethylene polymer material as the base material.

[0071] The structure of the barrier PE film of this embodiment is shown in Table 1, and includes a seven-layer structure of mLLDPE / HDPE / mLLDPE / HDPE / mLLDPE / HDPE / mLLDPE, wherein the HDPE functional layer and the non-HDPE in the film layer structure The functional layers (ie, mLLDPE functional layers) are alternately stacked, and each non-HDPE functional layer is based on a metallocene linear low density polyethylene material as a base material. The most central film layer of the film structure is the HDPE functional layer, and the HDPE functional layers and the non-HDPE functiona...

Embodiment 2

[0091] such as Figure 7 The fully recyclable barrier PE film material of the present invention as shown comprises seven superimposed film layer structures, the substrates of each film layer in the film layer structure are polyethylene polymer materials (PE), and the film layer structure It contains three-layer HDPE functional layer with high-density polyethylene polymer material as the base material.

[0092] The structure of the barrier PE film of this embodiment is shown in Table 2, and includes a seven-layer structure of mLLDPE / HDPE / mLLDPE / HDPE / mLLDPE / HDPE / mLLDPE, wherein the HDPE functional layer and the non-HDPE in the film layer structure The functional layers (ie, mLLDPE functional layers) are alternately stacked, and each non-HDPE functional layer is based on a metallocene linear low density polyethylene material as a base material. The most central film layer of the film structure is the HDPE functional layer, and the HDPE functional layers and the non-HDPE function...

Embodiment 3

[0100] such as Figure 8 The fully recyclable barrier PE film material of the present invention as shown comprises seven superimposed film layer structures, the substrates of each film layer in the film layer structure are polyethylene polymer materials (PE), and the film layer structure It contains two layers of HDPE functional layer with high-density polyethylene polymer material as the base material.

[0101] The structure of the barrier PE film of this embodiment is specifically shown in Table 3, including a seven-layer structure of mLLDPE / HDPE / mLLDPE / LLDPE / mLLDPE / HDPE / mLLDPE (which can also be mLLDPE / mLLDPE / HDPE / LLDPE / HDPE / mLLDPE / mLLDPE), wherein the HDPE functional layer and the non-HDPE functional layer (ie mLLDPE functional layer) in the film structure are not completely alternately stacked. The most central membrane layer of the membrane structure is the LLDPE functional layer, which is arranged symmetrically on both sides of the most central membrane layer in an al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com