Nanometer multifunctional aqueous anticorrosive paint

A multi-functional, anti-corrosion paint technology, applied in the field of anti-corrosion paint, can solve the problems of poor performance and high production cost of multi-functional water-based anti-corrosion paint, and achieve the effect of solving high production cost, poor performance and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Nano multifunctional water-based anti-corrosion paint, its components are proportioned by mass percentage: 10% water, 10% montmorillonite slurry, 25% epoxy modified polyvinyl alcohol solution, 0.2% dispersant, 4% film former, 0.2% defoamer, 0.2% fungicide, 40% acrylic emulsion, 0.6% thickener.

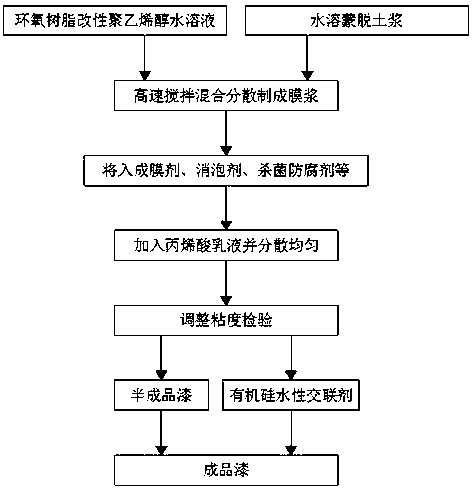

[0017] Preparation method: first modify polyvinyl alcohol with epoxy resin for water resistance, then mix and disperse it with montmorillonite slurry in a certain proportion to prepare nano-sized low-cost modified polyvinyl alcohol film-forming slurry, and then Cross-linking with acrylic emulsion to prepare a high-performance anti-corrosion paint, and then adding a silicone water-based cross-linking agent during use to completely change the water resistance of the anti-corrosion paint to obtain a finished paint.

Embodiment 2

[0019] Nano multifunctional water-based anti-corrosion paint, its components are proportioned by mass percentage: 10% water, 10% montmorillonite slurry, 25% epoxy modified polyvinyl alcohol solution, 0.2% dispersant, 4% film former, 0.2% defoamer, 0.2% bactericide, 40% acrylic acid emulsion, 0.6% thickener; the mass ratio of epoxy-modified polyvinyl alcohol aqueous semi-finished product is water 90%, polyvinyl alcohol 7%, epoxy resin 3%.

[0020] Preparation method: first modify polyvinyl alcohol with epoxy resin for water resistance, then mix and disperse it with montmorillonite slurry in a certain proportion to prepare nano-sized low-cost modified polyvinyl alcohol film-forming slurry, and then Cross-linking with acrylic emulsion to prepare a high-performance anti-corrosion paint, and then adding a silicone water-based cross-linking agent during use to completely change the water resistance of the anti-corrosion paint to obtain a finished paint.

Embodiment 3

[0022] Nano multifunctional water-based anti-corrosion paint, its components are proportioned by mass percentage: 10% water, 10% montmorillonite slurry, 25% epoxy modified polyvinyl alcohol solution, 0.2% dispersant, 4% film former, 0.2% defoamer, 0.2% bactericide, 40% acrylic acid emulsion, 0.6% thickener; the mass ratio of epoxy-modified polyvinyl alcohol aqueous semi-finished product is water 90%, polyvinyl alcohol 7%, epoxy resin 3%; wherein the mass ratio of the water-soluble montmorillonite slurry semi-finished product is 85% of water, 14% of montmorillonite, and 1% of antiseptic and bactericide.

[0023] Preparation method: first modify polyvinyl alcohol with epoxy resin for water resistance, then mix and disperse it with montmorillonite slurry in a certain proportion to prepare nano-sized low-cost modified polyvinyl alcohol film-forming slurry, and then Cross-linking with acrylic emulsion to prepare a high-performance anti-corrosion paint, and then adding a silicone wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com