Process for producing humic acid liquid suspension water-soluble fertilizer

A production process, humic acid technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of difficult dredging of pipelines, complicated operation, impact on production efficiency, etc., to improve anti-blocking and dredging, improve preparation efficiency, and contact area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

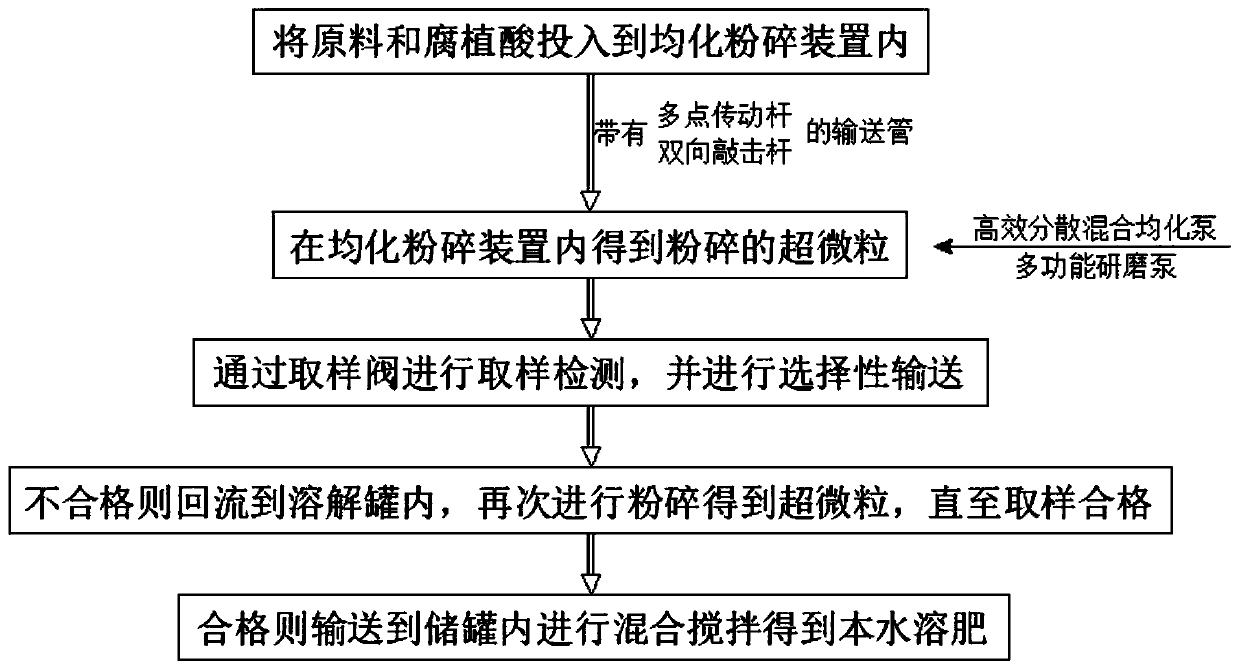

[0050] see figure 1 , a humic acid liquid suspension water-soluble fertilizer production process, comprising the following steps:

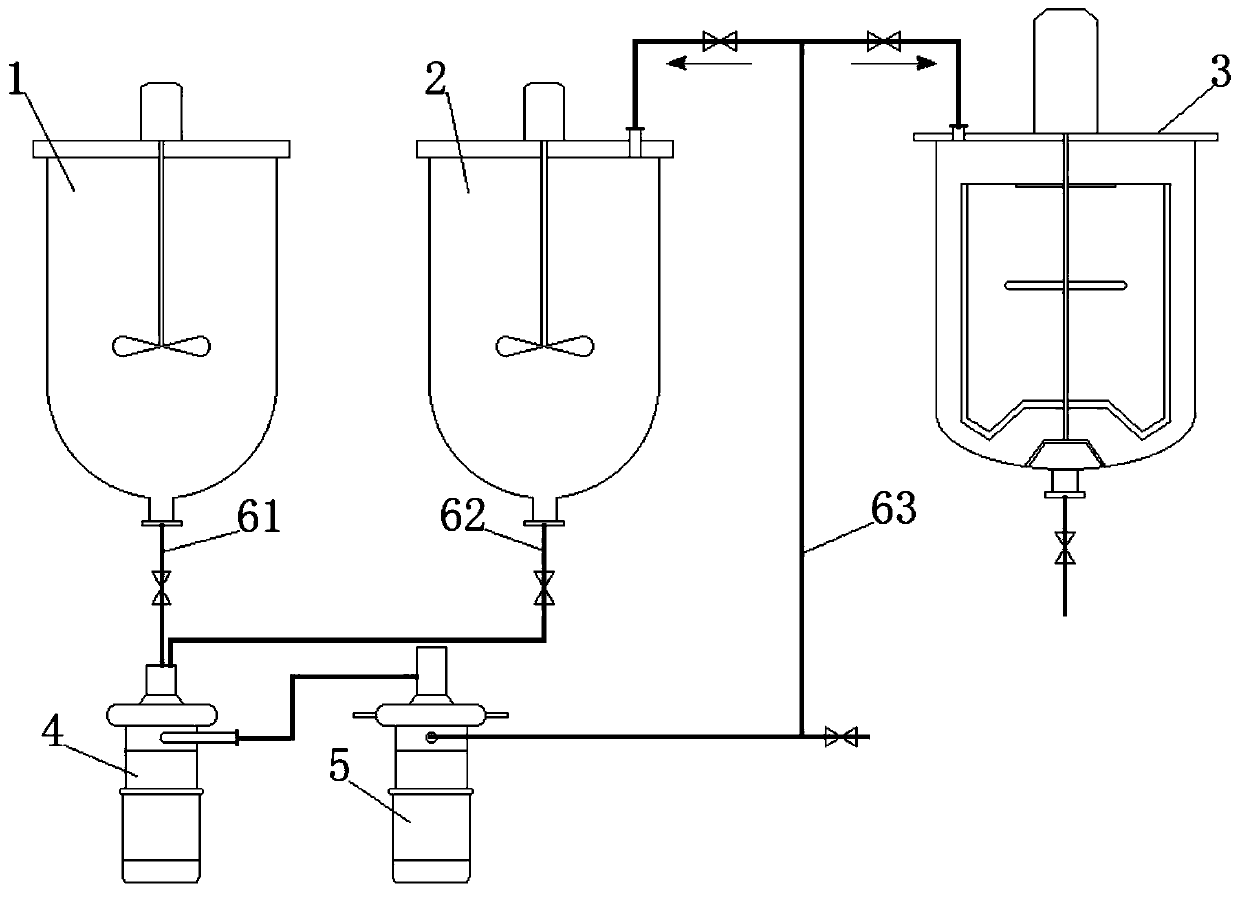

[0051] S1, first put the raw material and humic acid into the blending tank 1 and the dissolving tank 2 with a disperser in the homogenizing and pulverizing device respectively;

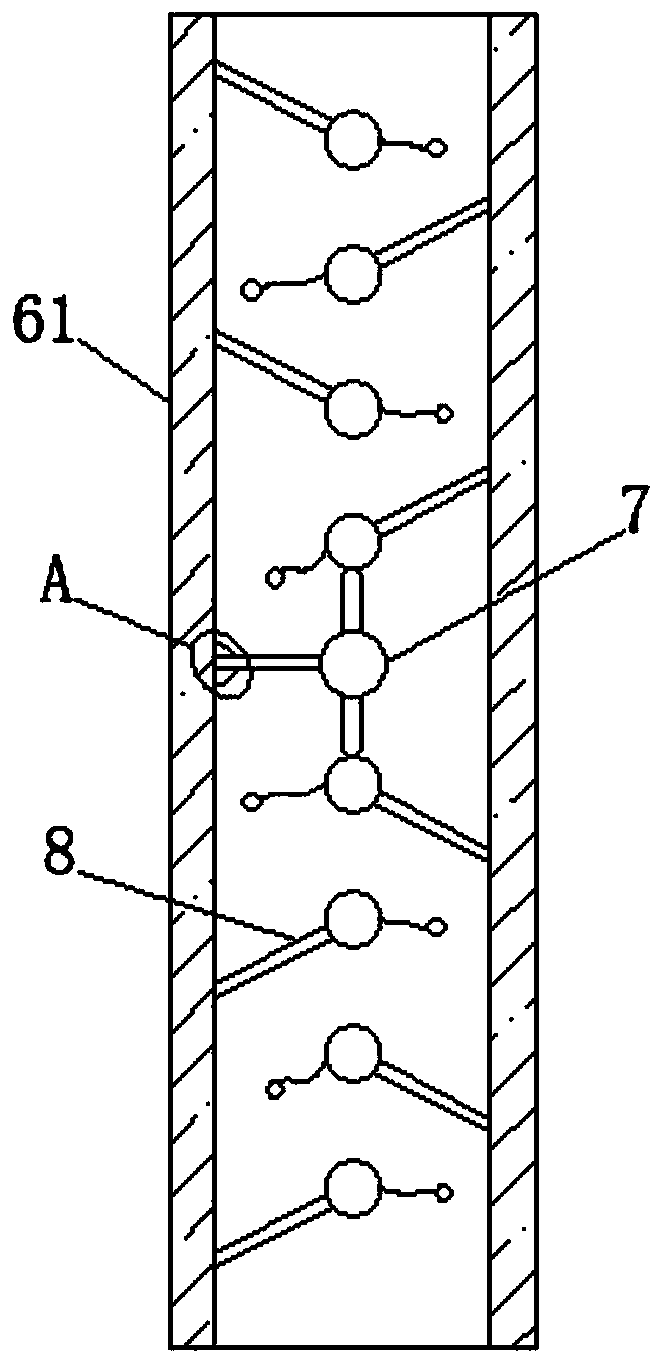

[0052] S2. Raw materials and humic acid pass through the conveying pipe with multi-point transmission rod 8 successively in the homogenizing and crushing device, and pass into the high-efficiency dispersing and mixing homogenizing pump 4 and the multi-functional grinding pump 5 for shearing and dispersing, Depolymerization stirring, mixing homogenization, emulsification and grinding to obtain pulverized ultrafine particles and continue to transport to the next step;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com