Purple biaxial-stretching polyester film and preparation method thereof

A biaxially stretched polyester, purple technology, applied in the field of polyester film, can solve the problems of complex preparation process, blue dye migration, haze reduction, etc., and achieve the effects of reduced manufacturing cost, reasonable temperature parameters, and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

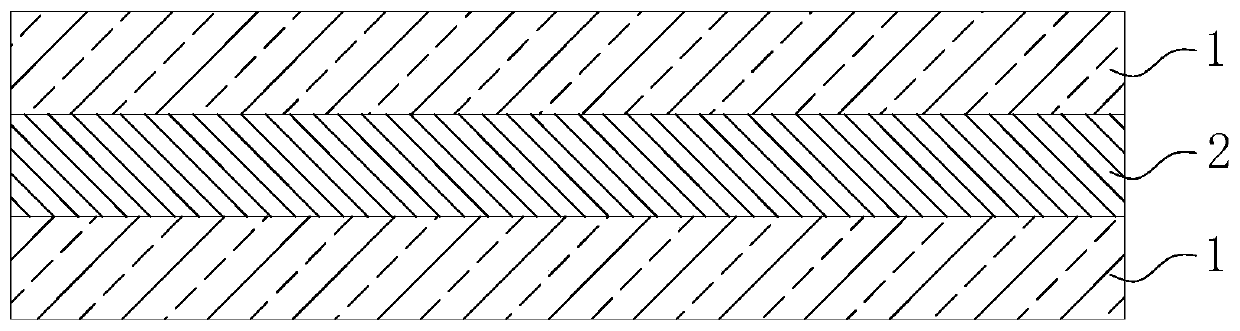

[0032] Such as figure 1 , a purple biaxially stretched polyester film, the purple biaxially stretched polyester film is an ABA type three-layer structure, the B layer is a colored layer, the A layer is located on both sides of the B layer, and the A layer is transparent layer, the raw materials of the B layer include: 0.2% to 15% of purple masterbatch and 85% to 99.8% of optical grade PET slices by mass percentage; the raw materials of the A layer include: 1% to 50% by weight Open masterbatch and 50% to 99% optical grade PET chips.

[0033] The scheme makes the purple double-stretched polyester film have good performance, widens the application range of the purple double-stretched polyester film, and reduces the use cost of the purple double-stretched polyester film.

no. 2 example

[0035] The total thickness of the A layer accounts for 20% to 50% of the total thickness of the purple biaxially stretched polyester film, and the thickness of the B layer accounts for 50% to 80% of the purple biaxially stretched polyester film.

[0036] The purple masterbatch comprises 3% to 14% of purple toner, 0.5% to 2% of dispersant and 80% to 95% of optical grade PET in the weight portion of the purple masterbatch.

[0037] The opening masterbatch comprises: 5% to 15% of calcium carbonate, 1% to 4% of silane coupling agent and 81% to 94% of optical grade PET in the weight of the opening masterbatch.

[0038] The calcium carbonate used is in a regular spherical shape, and the particle size of the calcium carbonate used is 0.5um to 1.6um.

[0039] The particle size of calcium carbonate is not specifically limited, and those skilled in the art can reasonably select it according to needs.

[0040] The total thickness of the purple biaxially stretched polyester film is 12um ...

no. 3 example

[0043] A preparation method for a purple double-stretched polyester film, comprising the following steps:

[0044] Grind optical-grade PET chips into polyester powder with a particle size of 0.5um to 0.8um, then mix polyester powder, quality purple toner and dispersant at a speed of 3500r / min to 4000r / min for 5min to 10min, Then adjust the rotation speed to 100r / min to 150r / min and mix for 2min to 3min. Finally, melt and knead the mixed raw materials at 265°C to 275°C, extrude and pelletize to obtain purple masterbatch;

[0045] Grind optical-grade PET slices into polyester powder with a particle size of 0.5um to 0.8um, then mix polyester powder, calcium carbonate, and silane coupling agent at a speed of 4000r / min to 5000r / min for 10min to 15min, Then adjust the rotation speed to 150r / min to 200r / min and mix for 3min to 5min. Finally, melt and knead the mixed raw materials at 265°C to 275°C, extrude and pelletize to obtain open masterbatch;

[0046]The prepared purple masterb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com