A five-axis linkage CNC machine tool

A CNC machine tool, five-axis linkage technology, applied in metal processing machinery parts, metal processing equipment, metal processing and other directions, can solve the problems of low efficiency, insufficient cutting rigidity, large Y-axis cantilever, etc., to increase the span and weight. Lightening, easy and quick discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

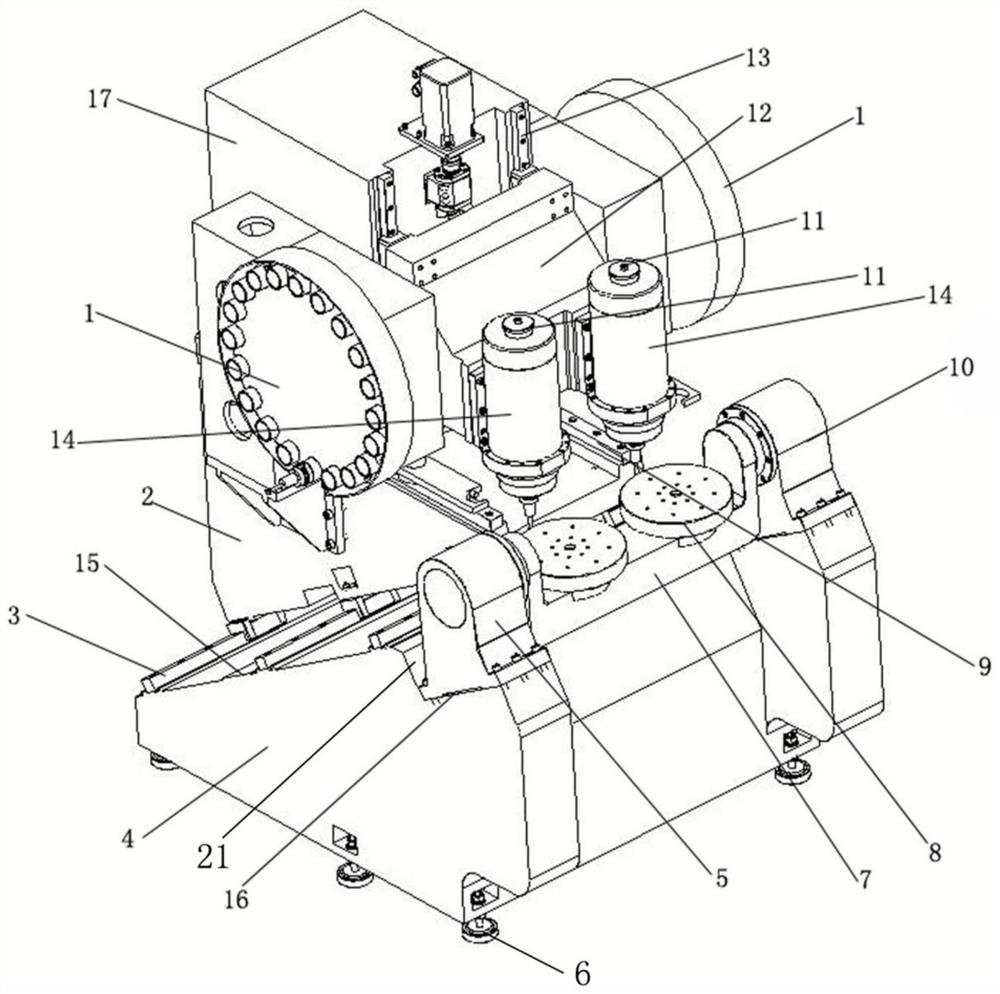

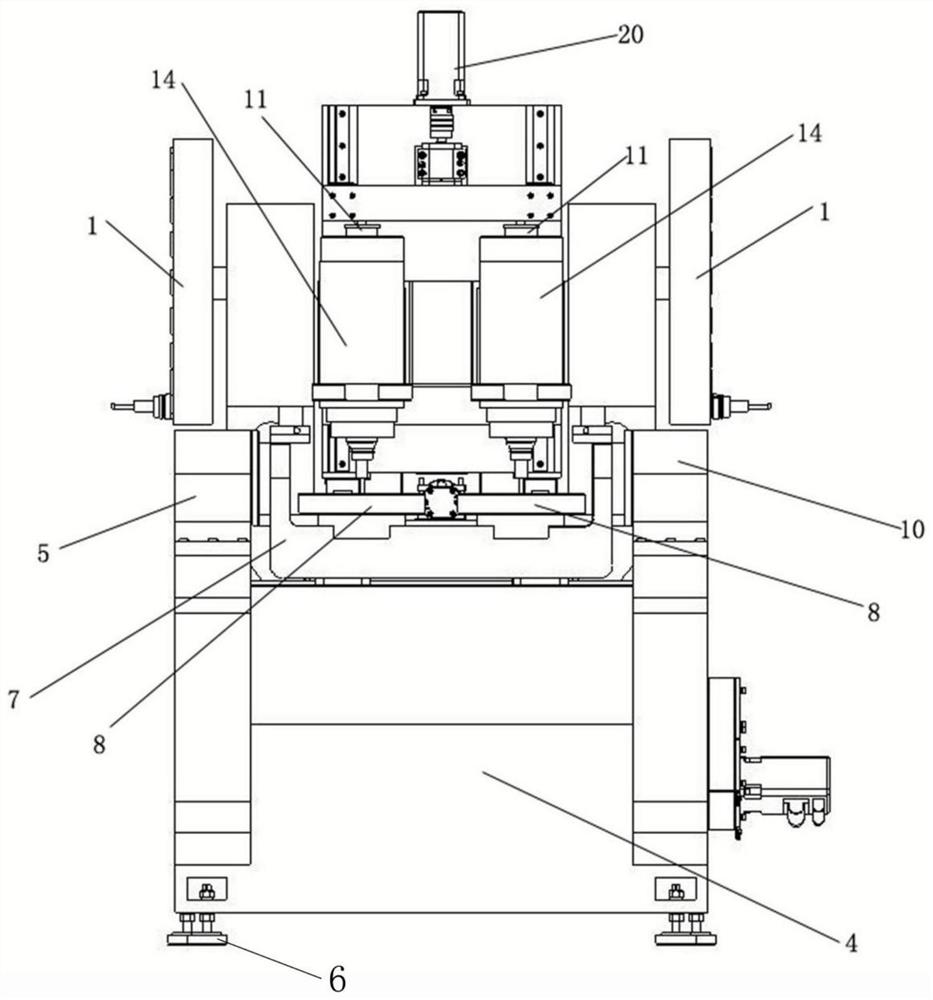

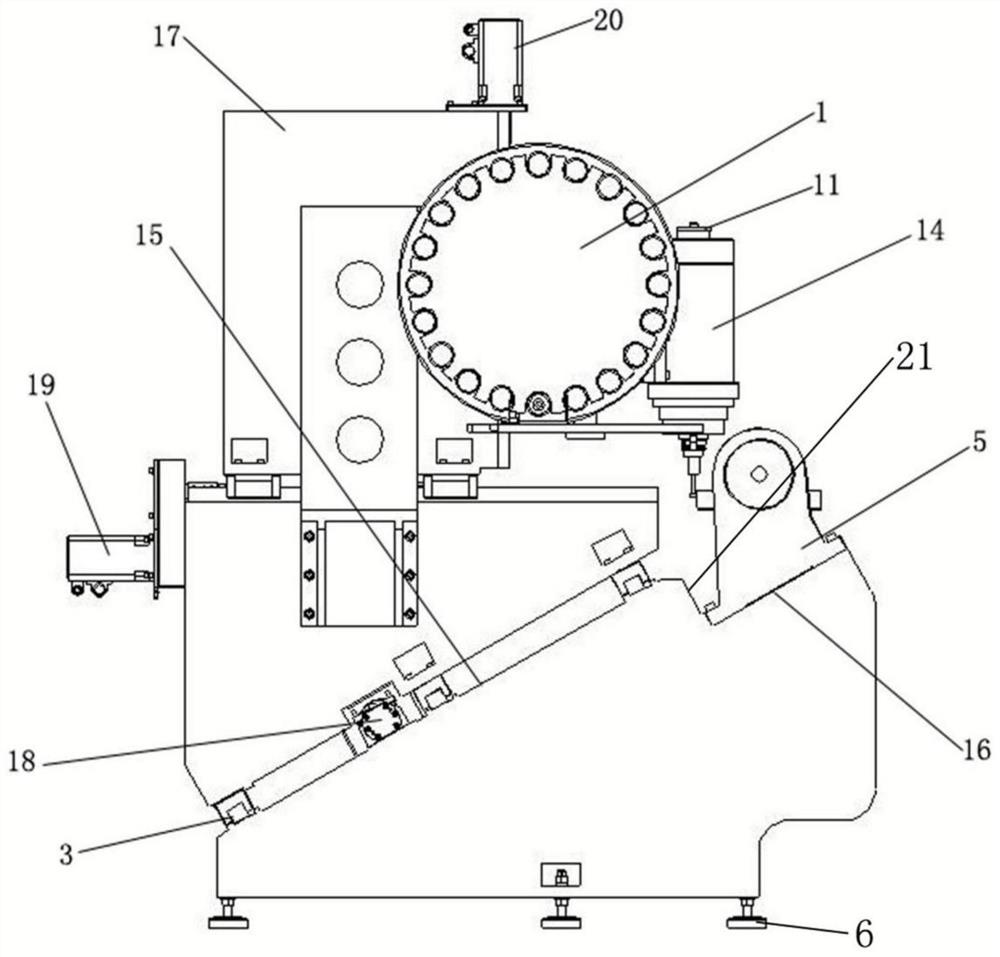

[0038] Figure 1-7 Shown is a five-axis linkage CNC machining center of the present invention. The five-axis linkage CNC machining center includes a bed 4 and two spindles 11 respectively driven by two headstocks 14 . The two main axes 11 are parallel to each other. The bed 4 has two inclined surfaces, a first inclined surface 15 and a second inclined surface 16 . In this embodiment, the first inclined surface 15 and the second inclined surface 16 are parallel to each other, the second inclined surface 16 is at the top of the bed 4 , and the first inclined surface 15 is at the rear of the bed 4 relative to the second inclined surface 16 . In this embodiment, the area of the second inclined surface 16 is smaller than the area of the first inclined surface 15 . vice versa. An X-axis sliding seat 2 is slidably installed on the first inclined surface 15 via an X-axis guide rail 3 . The X-axis sliding seat 2 is driven by the X-axis driving device 18 and moves along the X-ax...

Embodiment 2

[0042] still refer to Figure 1-7 , On the basis of Embodiment 1, a five-axis linkage impeller machining center is provided. In this embodiment, the difference from Embodiment 1 is that the number of worktables 8 is one.

Embodiment 3

[0044] still refer to Figure 1-7 , On the basis of Embodiment 1, a driving motor for driving two workbenches 8 to rotate is installed in the C-axis rotating body 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com